A method for forming a ceramic body

A ceramic embryo body and ceramic slurry technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of damage, cracking inside, embryo body cracks, etc., and achieve the effect of simple operation method and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] see Image 6 , Embodiment 1 of the present invention provides a method for forming a ceramic green body, which includes the following steps:

[0075] S30, calculating and preparing a molding die 140 according to the size of the ceramic product to be formed;

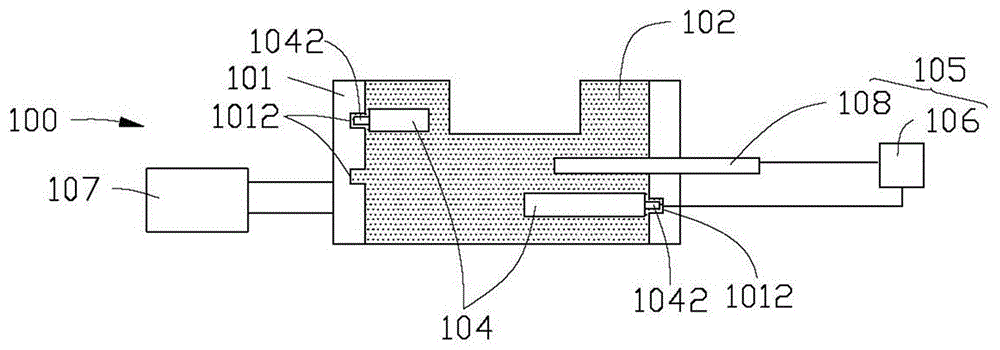

[0076] S31, placing the molding mold 140 on the vacuum vibration table 120, coating a coating film 103 on the surface of the molding mold 140, so that the coating film 103 is attached to the surface of the molding mold 140;

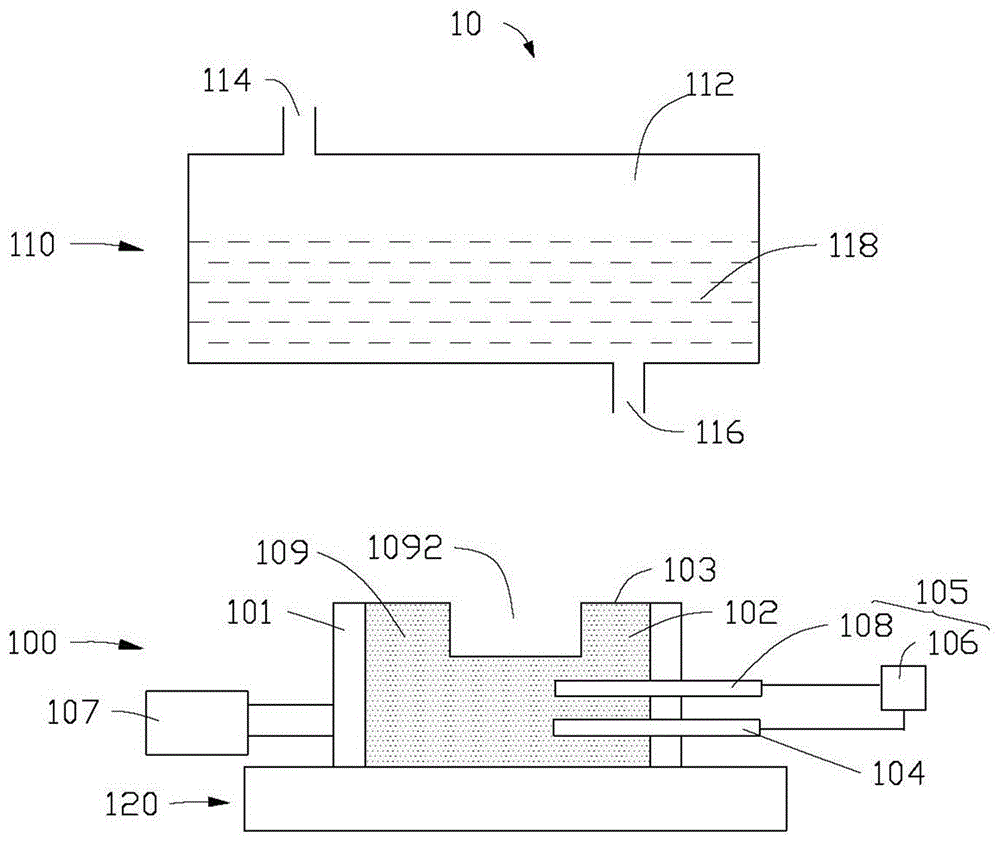

[0077] S32, place the sand box 101 on the vacuum vibrating table 120 and cover the molding mold 140, then fill the sand box 101 with molding sand 102, vibrate the molding sand 102 through the vacuum vibrating table 120 and scrape the molding sand 102 Spread a film 103 on the surface and keep the molding sand 102 in vacuum;

[0078] S33, release the vacuum of the vacuum vibrating table 120, hold up the sand box 101 and take off the molding mold 140, turn over the sand box 101, the molding san...

Embodiment 2

[0089] see Figure 7 , Embodiment 2 of the present invention provides a method for forming a ceramic green body, which includes the following steps:

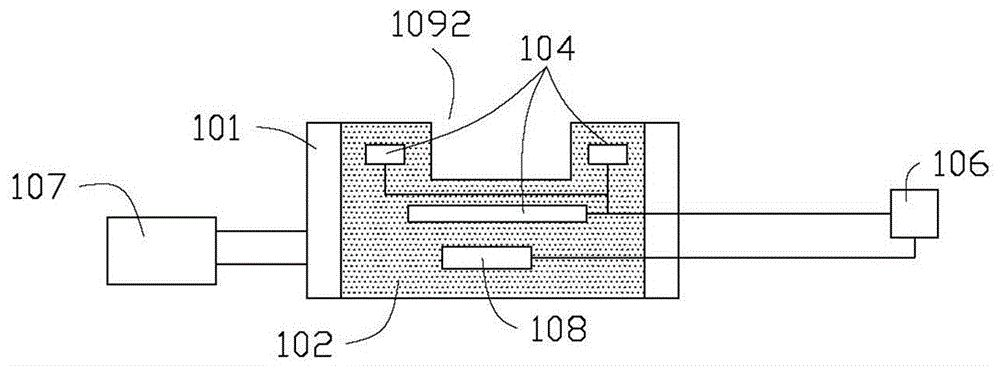

[0090] S40, calculating the size of the molding die 140 according to the ceramic product that needs to be formed, and determining the parting surface according to the shape of the ceramic body, the molding die 140 is divided into an upper mold 142 and a lower mold 144 by the parting surface;

[0091] S41, placing the upper mold 142 and the lower mold 144 on the vacuum vibration table 120 respectively, and laying a coating film 103 on the surface of the upper mold 142 and the lower mold 144, so that the coating 103 is attached to the upper mold 142 and the lower mold 144 surfaces;

[0092] S42, set a sprue and a riser core on the surface of the upper mold 142, place the sand box 101 on the vacuum vibration table 120 and cover the upper mold 142 and the lower mold 144 respectively, and then fill the sand box 101 with molding sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com