A jet electrodeposition nozzle and its method for manufacturing seamless metal pipe

A technology of jet electrolysis and electrodeposition, which is applied in the direction of electroforming and electrolysis, can solve the problems of poor adaptability, low production efficiency, and difficult demoulding, and achieve the effect of strong flexible manufacturing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

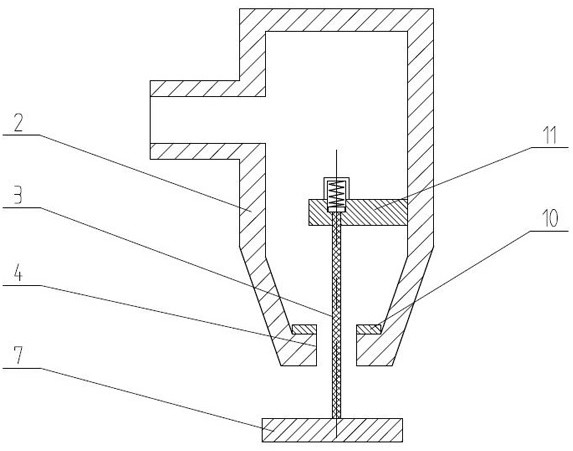

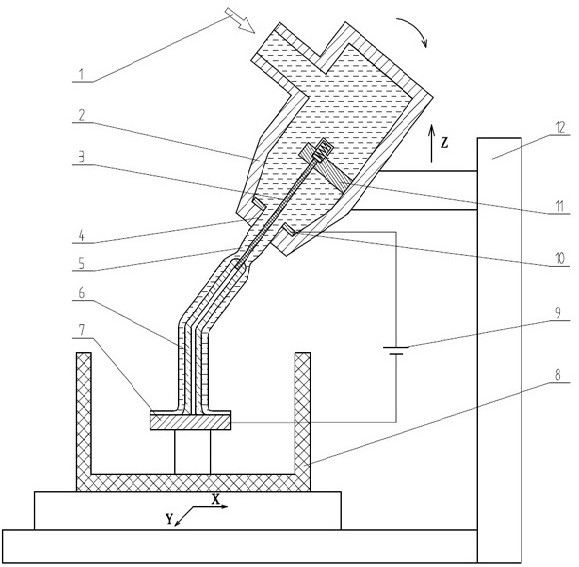

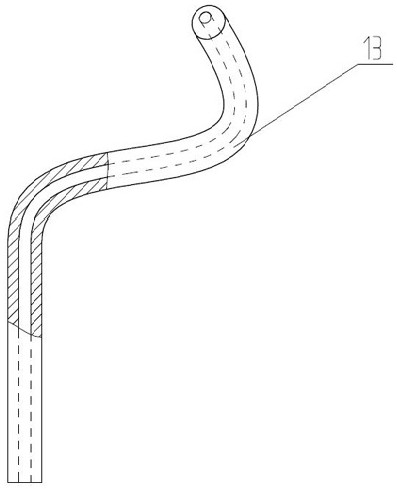

[0028] In the jet electrodeposition nozzle described in the present invention, the nozzle body 2 is made of plexiglass (PMMA). The nozzle body 2 is provided with a nozzle 4 with a diameter of 1 mm communicating with the electrolyte 1. The support frame 11 inside the nozzle body is installed with a diameter of 0.3 The polypropylene round rod of mm is used as the electrical insulation mold core 3, and the adjustment mechanism on the support frame can make the electrical insulation mold core 3 and the center of the nozzle 4 coaxial, and the protruding end plane of the electrical insulation mold core 3 exceeds the nozzle outlet by 3mm. A ring-shaped platinum sheet with an outer diameter of 3 mm and an inner diameter of 1 mm is coaxially fixed at the inlet of the nozzle 4 as a conductive anode 10 . The cathode substrate 7 is a square brass sheet wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com