Method and device for continuously hydrolyzing corn bran

A corn husk and hydrolyzate technology, which is applied in the field of corn deep processing, can solve the problems of high energy consumption, low hydrolyzate quality and production efficiency, and achieves the effects of low energy consumption, convenient automatic operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for continuous hydrolysis of corn bran, comprising the following steps:

[0036] (1) corn bran is mixed with sulfuric acid with a concentration of 1.5%, presoaked for 10 minutes, and the amount of sulfuric acid added is 9 units of sulfuric acid per unit weight of corn bran;

[0037] (2) After the material mixed and pre-soaked in step (1) is heated to 118° C. by means of jet instant heating with steam as the heat source, it is hydrolyzed for 3 hours to obtain a hydrolyzed solution;

[0038] (3) The hydrolyzate prepared in step (2) is reduced to 80-85° C. by means of flash cooling, and the hydrolyzate and slag are separated by pressing with a screw press;

[0039] After testing, the solid content of the hydrolyzate is 9.3%, and the main components are as follows:

[0040] Salt 31.24%, glucose 19.53%, xylose 29.62%, arabinose 16.32%, and the rest impurities.

Embodiment 2

[0042]The hydrolyzate prepared in Example 1 and corn bran were mixed in a weight ratio of 1:9, presoaked for 10 minutes, and the operations of step (2) and step (3) of Example 1 were repeated.

[0043] After testing, the solid content of the hydrolyzate is 17.1%, and the main components are as follows:

[0044] 25.03% salt, 20.92% glucose, 31.79% xylose, 19.96% arabinose, and the remaining impurities.

[0045] After cyclic hydrolysis, the solid content is nearly doubled, and the proportion of sugar components is basically unchanged, which saves the consumption of sulfuric acid and energy consumption.

Embodiment 3

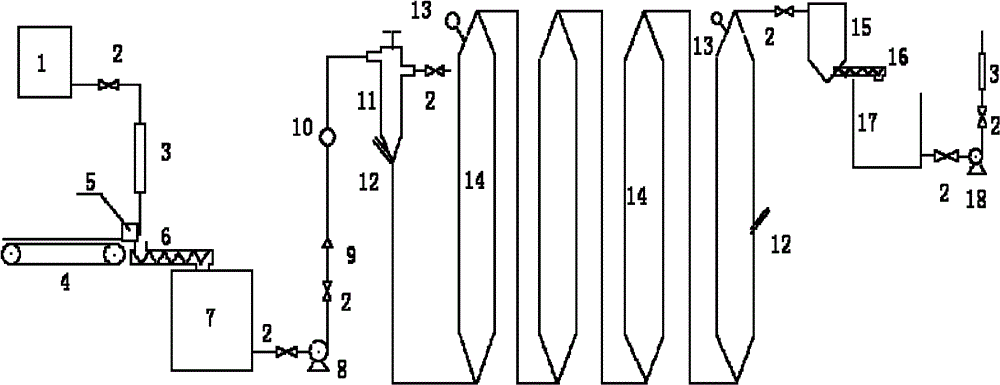

[0047] The special equipment for the above-mentioned continuous hydrolysis method of corn bran, such as figure 1 As shown, it includes a material supply device, a mixing device, a heating device, a hydrolysis reactor, a cooling device, and a pulp and slag separation device. The feed port is connected, the discharge port of the heating device is connected with the feed port of the hydrolysis reactor, the discharge port of the hydrolysis reactor is connected with the feed port of the cooling device, the discharge port of the cooling device is connected with the pulp and slag separation device The feed port of the pulp-slag separation device is connected with the feed port of the slurry discharge pipe and the mixing device respectively.

[0048] The above-mentioned material supply device includes an acid liquid storage tank 1, a flow meter 3, a belt feeder 4, and an impact type bulk solid flow meter 5, and the liquid feed port of the acid liquid storage tank 1 and the impact type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com