Composite plate

一种叠合板、叠板的技术,应用在楼板、建筑构件、建筑等方向,能够解决整体性差、难等效双向板、施工周期难度大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

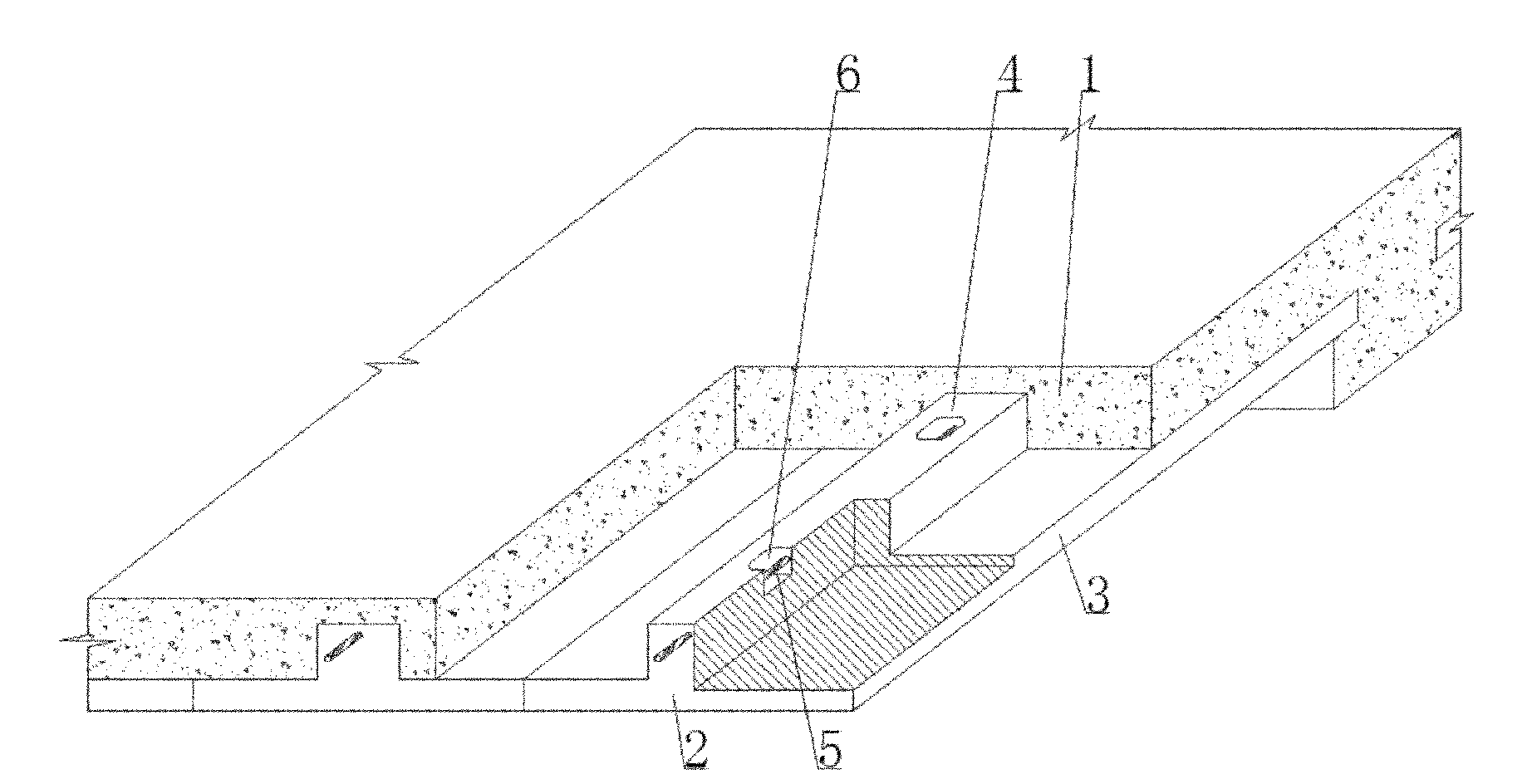

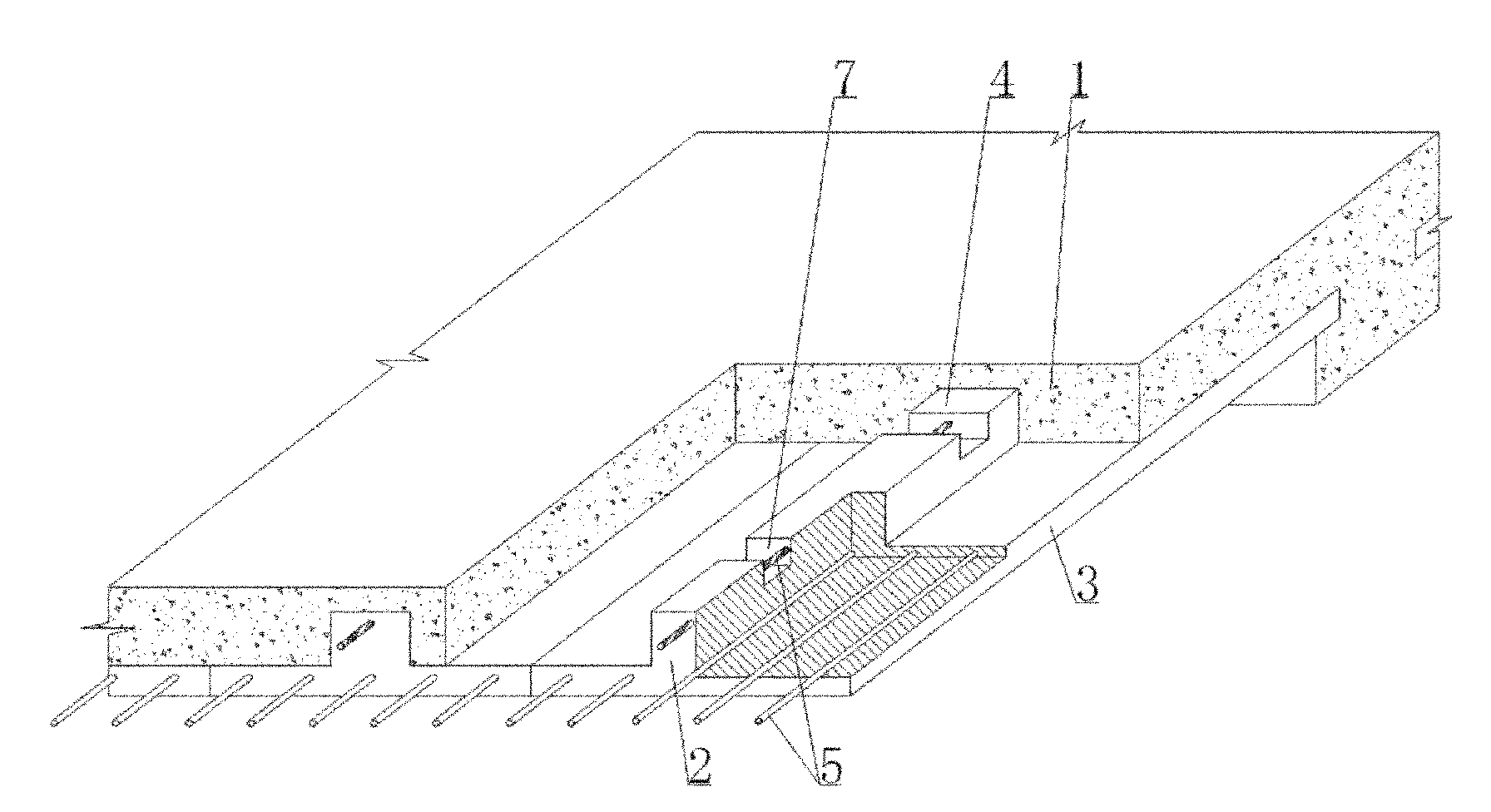

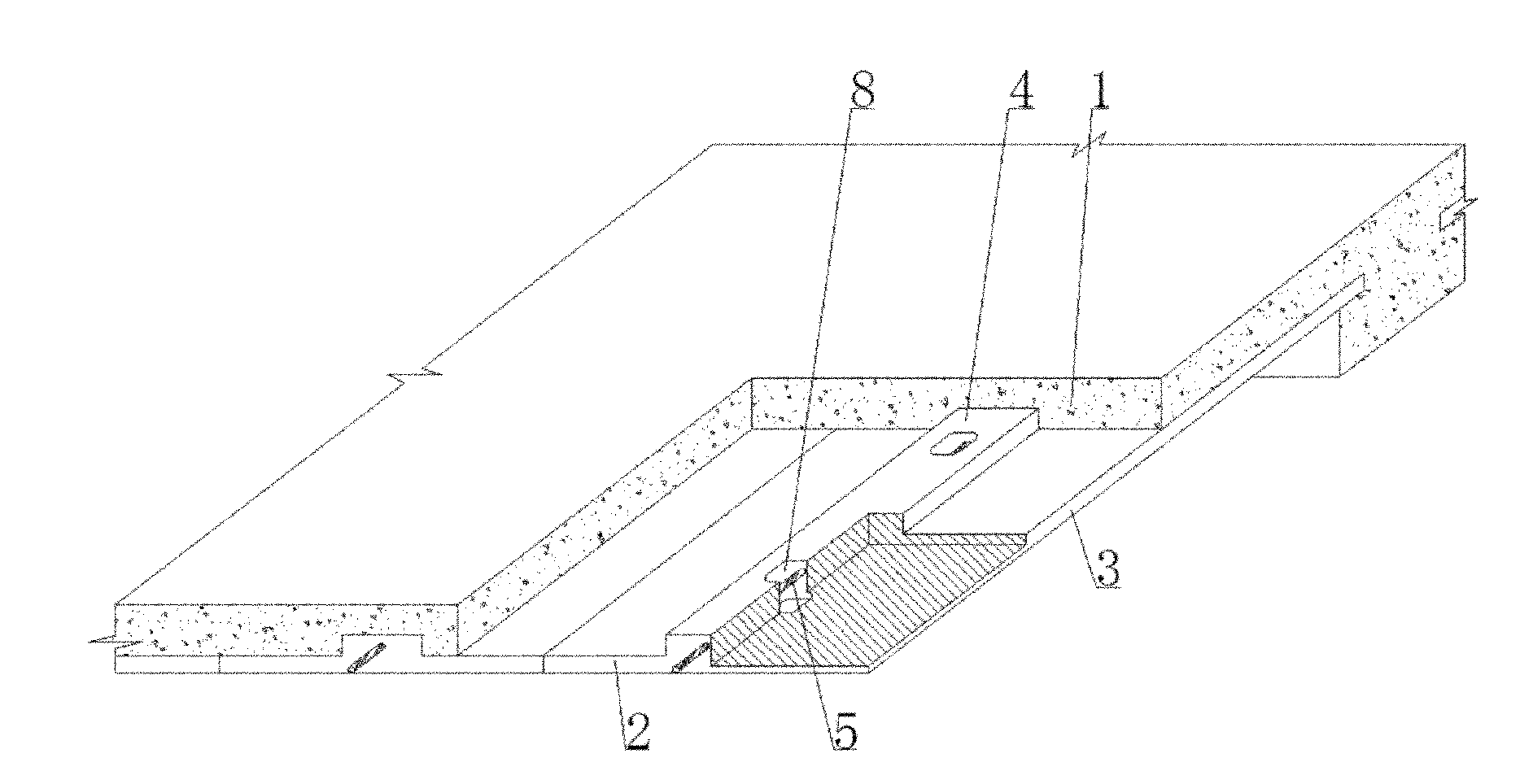

[0065] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0066] As shown in the drawings, the present invention includes reinforced concrete 1 and reinforced concrete ribbed prefabricated slab 2, the reinforced concrete ribbed prefabricated slab 2 is arranged at the bottom of the laminated slab, and the reinforced concrete ribbed prefabricated slab 2 includes a reinforced concrete strip-shaped bottom plate 3. The longitudinal long rib 4 of reinforced concrete is characterized in that the longitudinal long rib 4 is provided with a longitudinal or transverse steel bar 5, and the steel bar 5 is a pit 6 or / and a groove 7 or / and a hole 8 on the longitudinal long rib 4 The prestressed steel bars on the outside of the longitudinal long rib 4 are exposed to form a two-way structural load-bearing composite slab combined with cast-in-place and prefabricated. In the attached drawings, 1 is reinforced concrete, 2 is rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com