Perforating structure of motor power leading-out wire

A technology of motor power supply and lead-out wires, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of easy deformation of the sealing ring, and easy gaps between the sealing ring and the power lead-out wires, and achieve the effect of strengthening the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

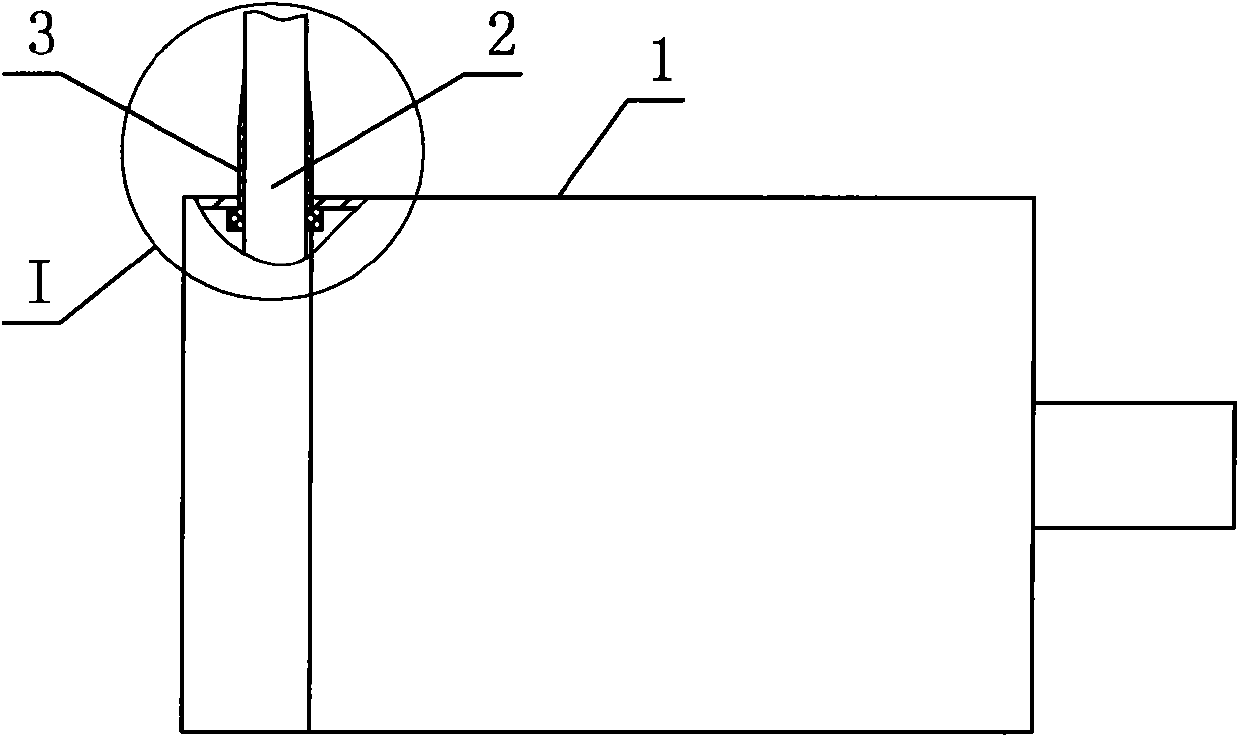

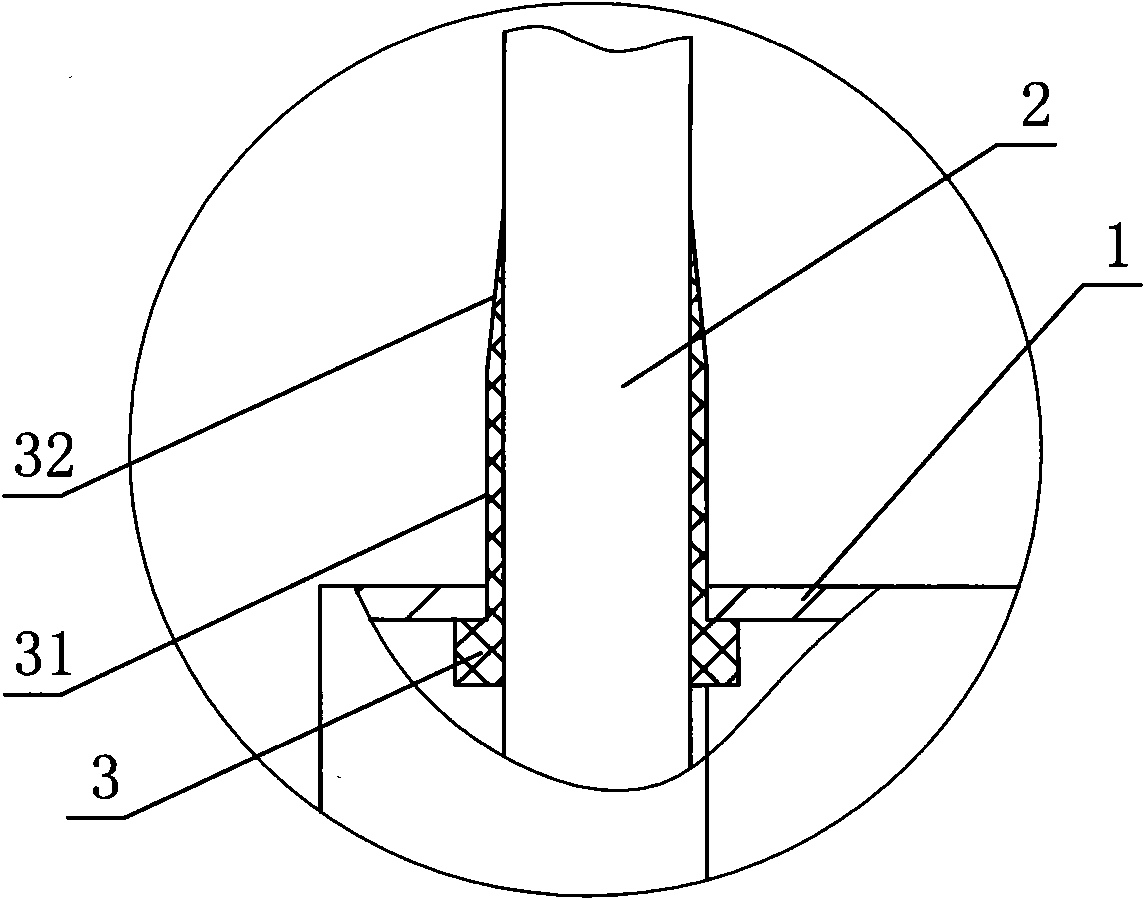

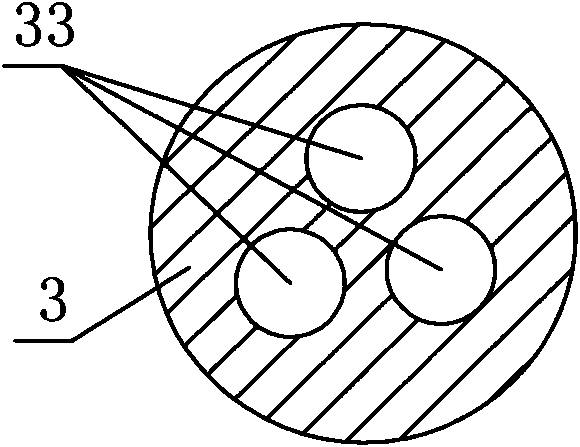

[0013] Such as figure 1 with figure 2 As shown, it is the structure of the motor power supply lead-out line of the present invention, including a casing 1 and a power supply lead-out line 2 passing through the hole in the casing. A sealing ring 3 is provided between the power supply lead-out line and the casing perforation, and the sealing ring 3 The outer port is provided with an extension section 31 protruding from the casing, and the port 32 of the extension section is a cone structure, and the length of the extension section is 5-10 cm. When multiple power lead wires pass through the same case, if image 3 , The through holes in the sealing ring are composed of several independent single-line perforations 33 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com