Pressing and breakover process and laminating board structure of circuit board

A circuit board and conduction technology, which is applied in the manufacturing process and structure of circuit boards, can solve product quality problems, high cost of laser drilling blind hole conduction process, hole deformation and other problems, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

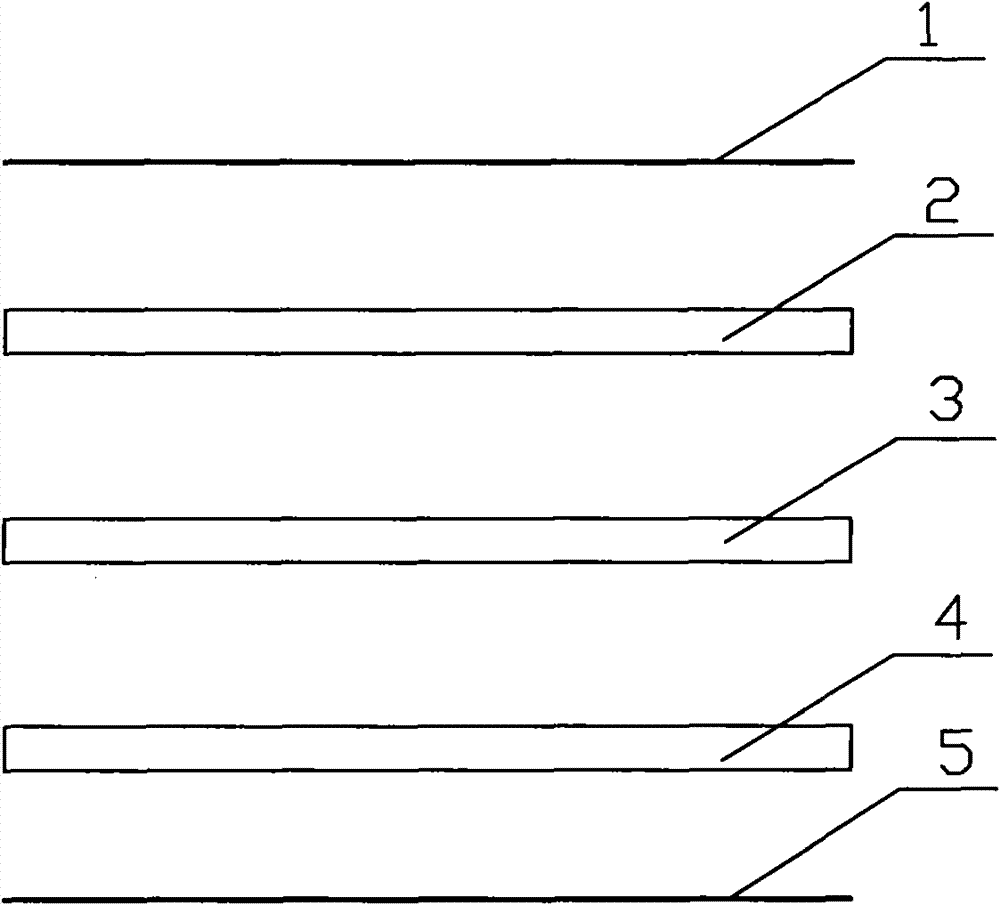

[0029] Such as figure 1 To and image 3 As shown, a press-fit and conduction process of a circuit board includes an inner layer board and an outer layer board prepared by blanking, and the processing technology mainly includes the following steps,

[0030] A. Fabrication of the inner layer board circuit. After the inner layer board is coated with copper, the designed circuit diagram is transferred to the board through the film, and then the required circuit is obtained by etching the inner layer board;

[0031] B, outer layer plate pressing, described outer layer plate and the inner layer plate obtained through step A are pressed;

[0032] C, drilling, the multi-layer board obtained in step B is drilled, so that the corresponding lines on the upper and lower positions of the circuit board are conducted by drilling;

[0033] D, electroplating, make the hole wall of step C conduction by electroplating;

[0034] E. Printing, through printing, the holes on the circuit board are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com