Gear grinding tool and method of using gear grinding tool

A technology for grinding tools and gears, applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing devices, manufacturing tools, etc., can solve the problem that gear grinding tools cannot achieve machining accuracy, the service life of the finishing area is over, and the service life is not available. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring to the accompanying drawings, a gear grinding tool according to a preferred embodiment of the present invention is described in detail below regarding a method of using the gear grinding tool.

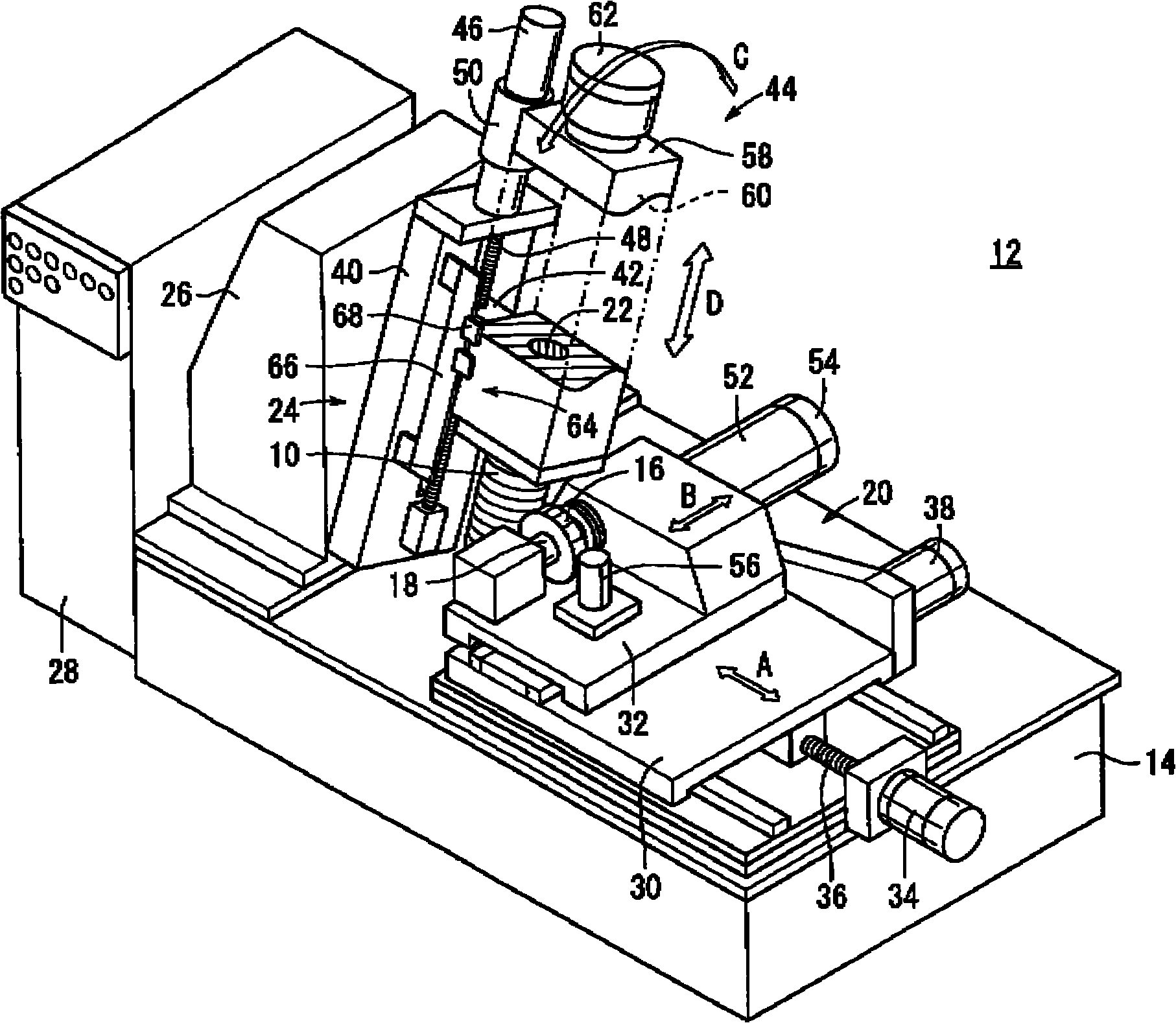

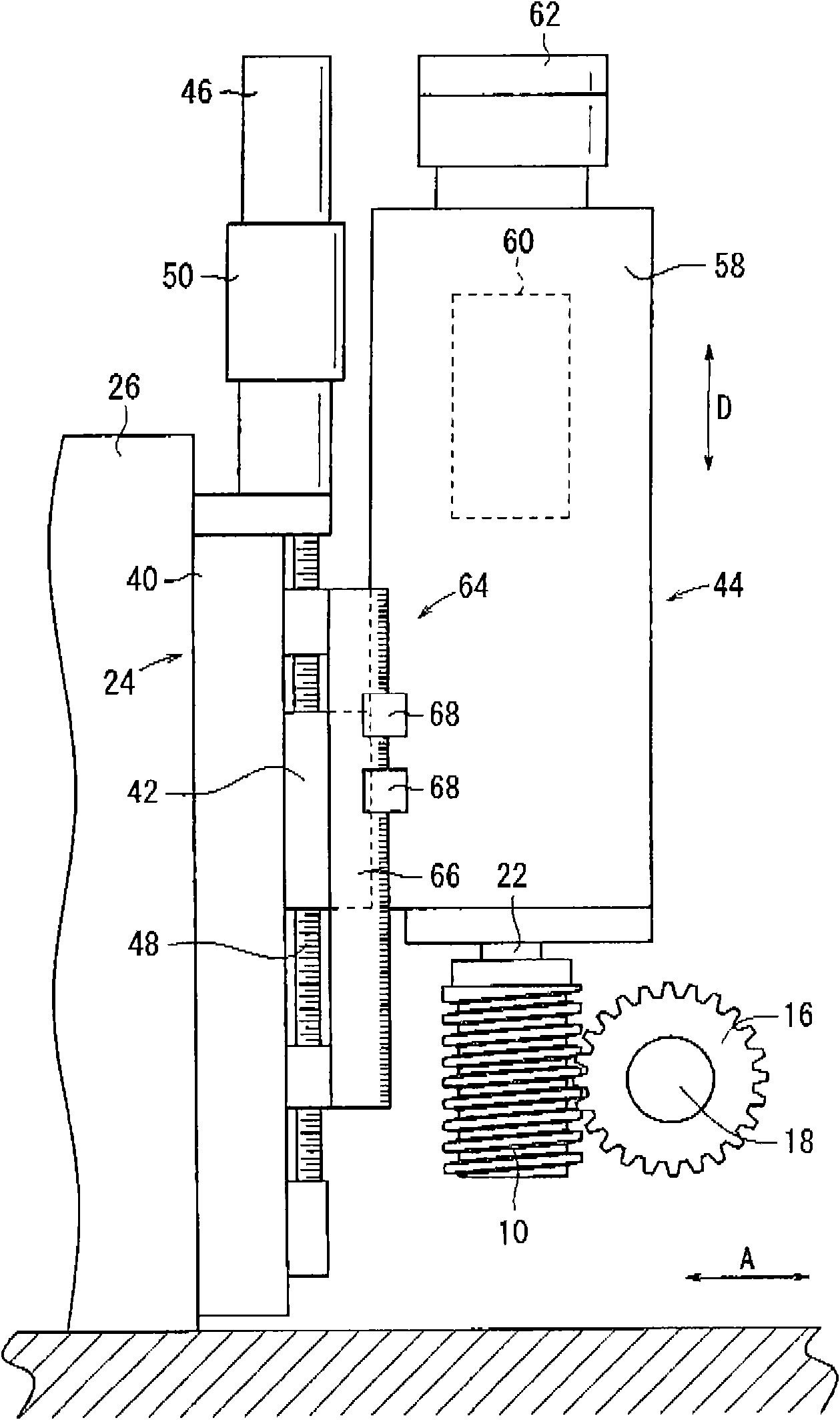

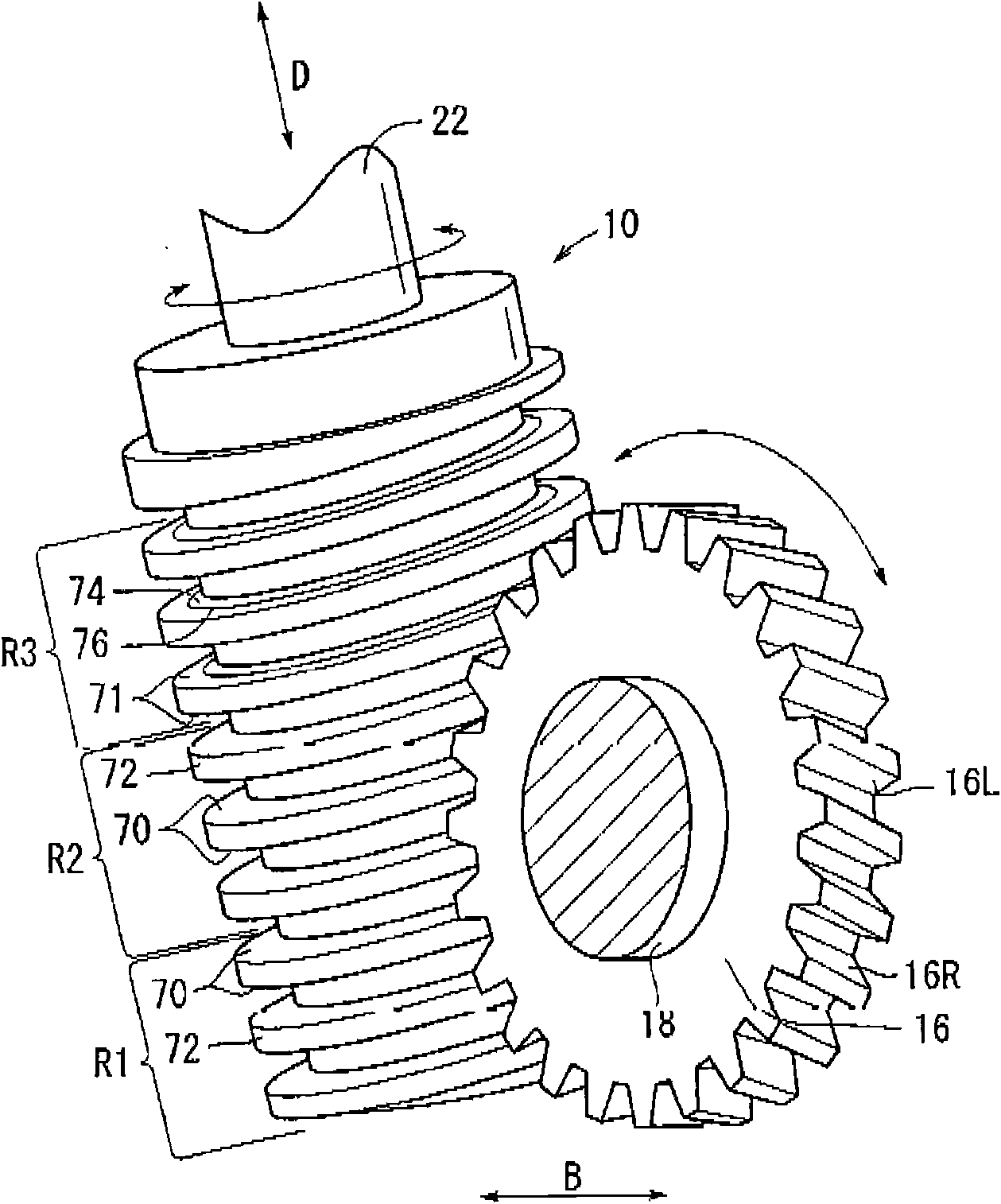

[0027] figure 1 is a perspective view of a gear grinding machine 12 incorporating therein a gear grinding tool 10 according to an embodiment of the present invention. figure 2 yes figure 1 A partial front view of the tool shaft and proximal portion of the gear grinder 12 is shown. The gear grinding tool 10 constitutes a tool mounted on a tool shaft of a gear grinding machine 12 to grind tooth surfaces of gears mounted on a work shaft of the gear grinding machine 12 .

[0028] Such as figure 1 with figure 2 As shown, the gear grinding machine 12 includes: a bed 14; a workpiece shaft 18 for holding a gear 16 to be ground as a workpiece above the bed 14; a movable table mechanism 20 for supporting the workpiece shaft 18 thereon , the workpiece shaft 18 is movable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com