Hoop composite insulating brick or building block and manufacturing and building methods thereof

A technology of composite thermal insulation and manufacturing methods, which is applied in the direction of construction, building materials, building components, etc., can solve the problems of insufficient durability and safety, affecting the overall quality of products, and low product strength, so as to ensure stability, improve work efficiency, and variety. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described below in conjunction with the accompanying drawings.

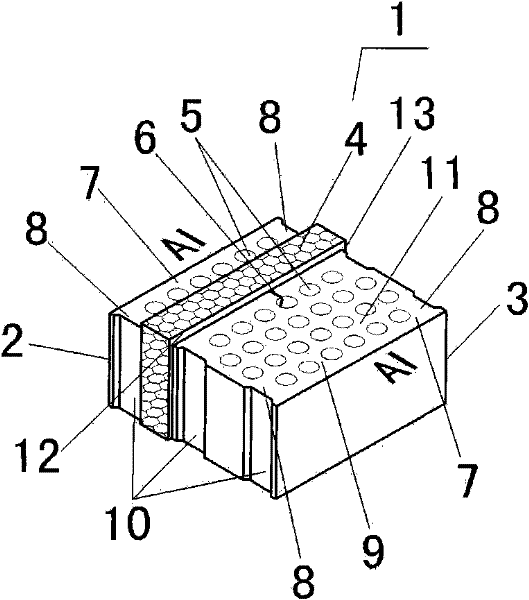

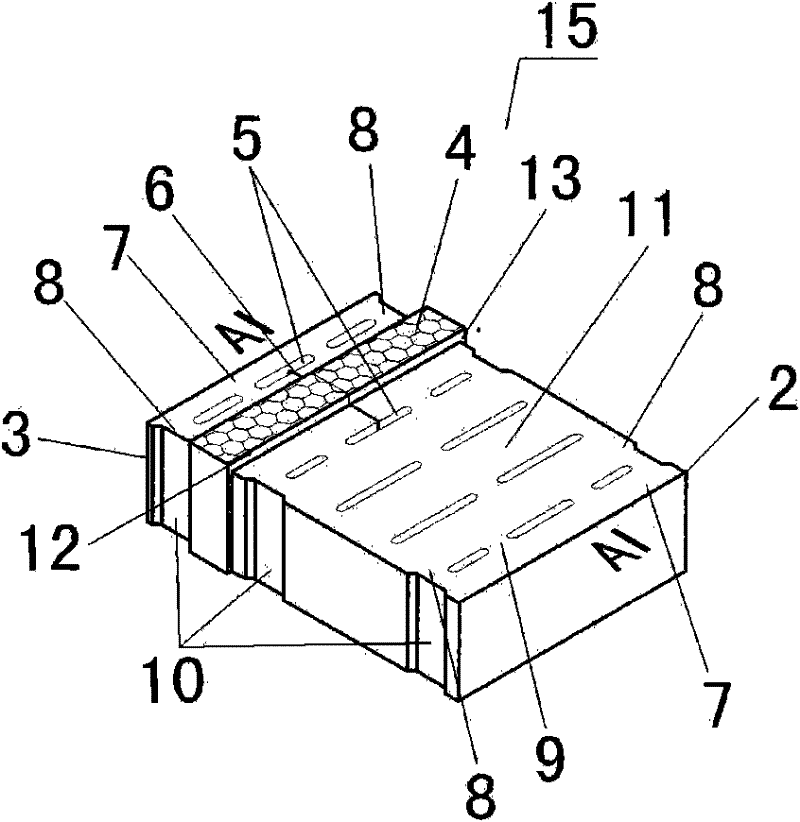

[0034] Technical scheme of the present invention figure 1 The hoop-type sintered porous composite thermal insulation brick 1 is composed of an inner leaf block 2, an outer leaf block 3, an insulating body 4, and a hoop 6 passing through the holes 5 in the inner leaf block 2 and the outer leaf block 3. The leaf block 2 and the outer leaf block 3 are provided with a bar wall 7 , a top wall 8 , a hole 5 , and a rib 9 , and vertical mortar tanks 10 are symmetrically arranged on the top wall 8 . The part 12 of the thermal insulation body 4 protruding from the grouting surface 11 can block the horizontal mortar in the wall, and the part 13 protruding from the top wall 8 can block the vertical mortar in the wall.

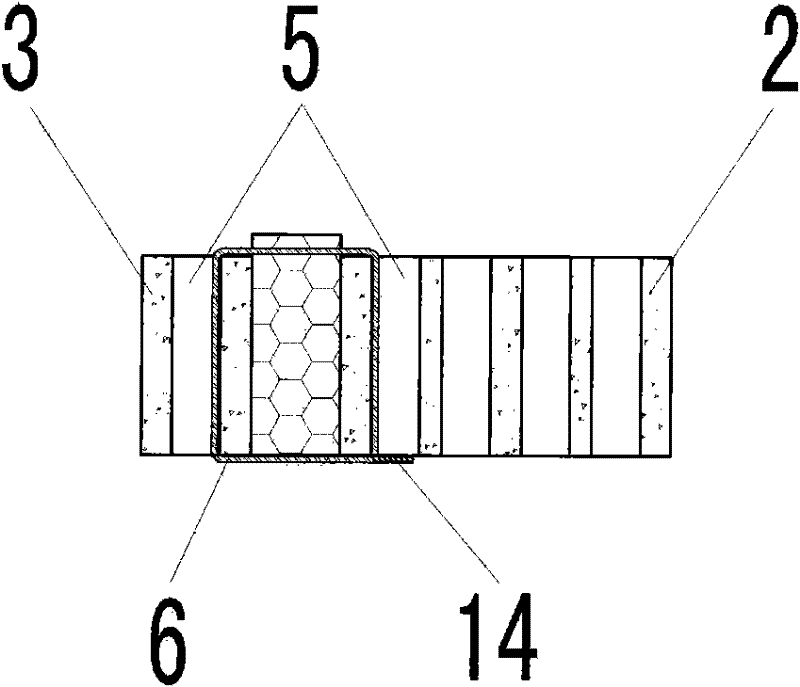

[0035] Technical scheme of the present invention figure 2 Yes figure 1 The cross-sectional view of the A-A direction of the hoop type sintered porous composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com