Axial adjusting device of butterfly valve shaft

A technology for regulating devices and butterfly valves, which is applied in the direction of valve devices, lifting valves, engine components, etc., can solve the mismatch between the sealing ring of the valve body and the sealing ring of the butterfly plate, and the inaccuracy of the cooperation between the sealing ring of the valve body and the sealing ring of the butterfly plate Advanced problems, to achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

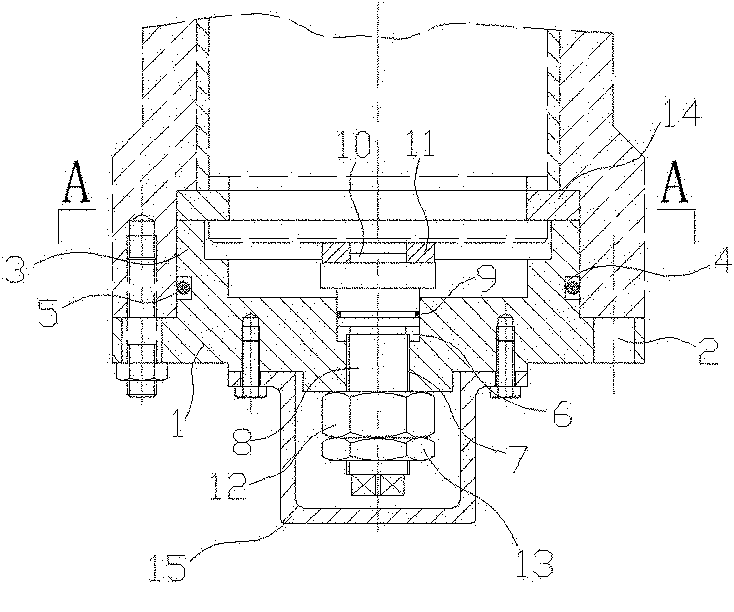

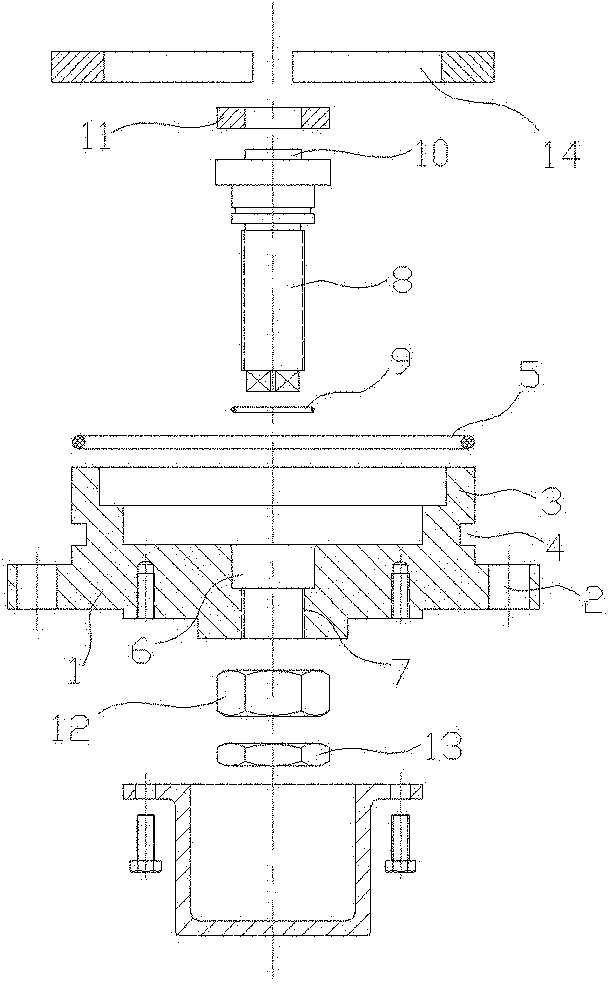

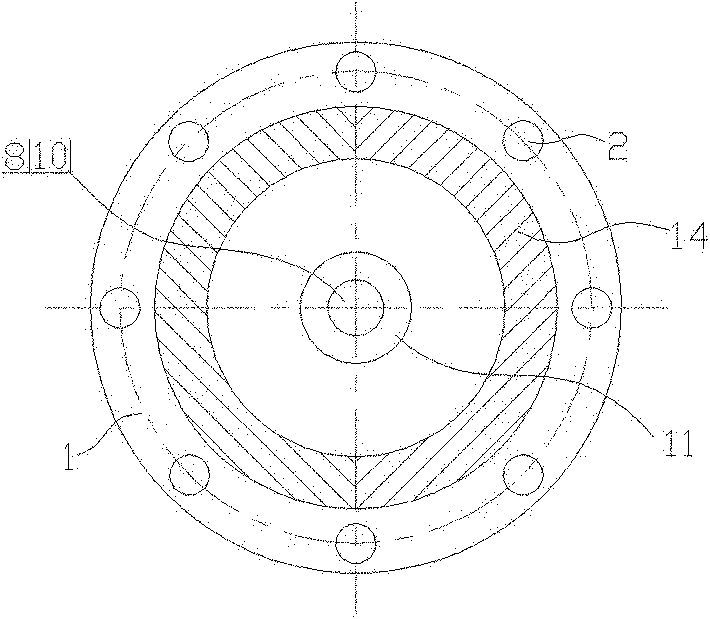

[0014] Figure 1~Figure 3 Among them, the axial adjustment device of the butterfly valve shaft has a circular end cover 1, the outer circumference of the end cover surface is evenly distributed with axial circular holes 2, and the top of the end cover is connected with a raised cylinder 3, and the end cover cylinder There is a groove 4 along the circumference on the outer circumference, a sealing ring 5 is arranged in the groove, a round hole 6 is arranged in the center of the end cover, and the lower section of the round hole is an internally threaded hole 7, and an adjusting screw 8 is screwed inside the internally threaded hole section. There is a sealing ring 9 between the adjusting screw and the upper section of the round hole, the upper end of the adjusting screw has a circular protrusion 10, the circular protrusion is covered with a circular friction pad 11, and the lower end of the adjusting screw is screwed with a fastening nut 12 in turn. With fastening nut 13, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com