Conjugated dendritic electrically-induced pure red material and preparation method and use thereof

A dendritic and conjugated technology, applied in luminescent materials, chemical instruments and methods, circuits, etc., can solve the problems of reduced luminous efficiency of devices, aggregation of small molecule luminescent materials, unsuitable for industrialized large-scale production, etc., to reduce excitation Formation of base complexes, reduction of fluorescence self-quenching, and improvement of energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

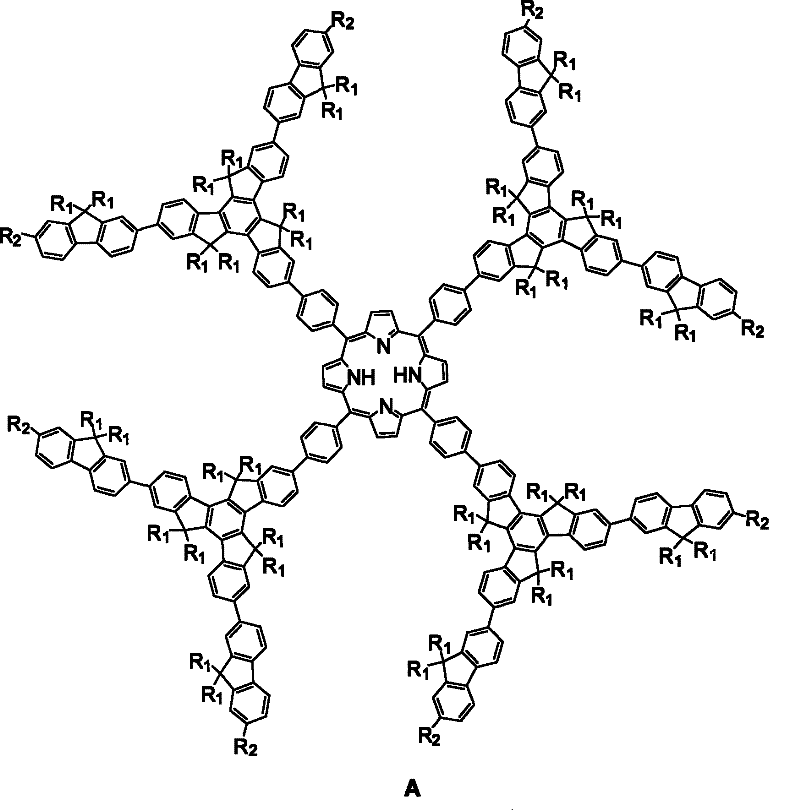

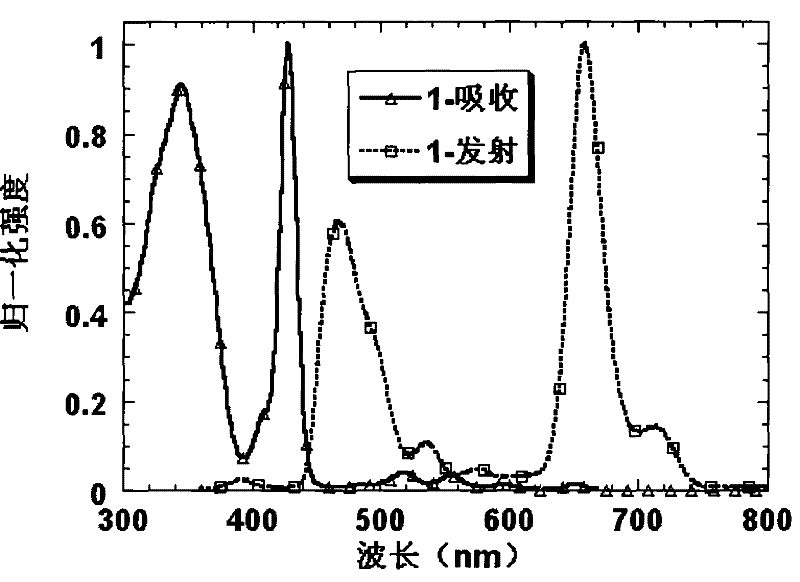

[0031] Embodiment 1: Preparation of compound 1 and its property determination

[0032] Suzuki reaction of bromide 3 with boronate 4 as shown below affords compound 5. Compound 1 is then obtained under the catalysis of boron trifluoride:

[0033]

[0034] where: R 1 =n-C 6 h 13

[0035] (1) Preparation of Compound 5:

[0036] Bromide 3 (0.15mmol), borate 4 (0.90mmol), potassium phosphate (1.80mmol) and catalyst Pd(PPh 3 ) 4 (5mol%) is added in the three-necked reaction flask that reflux condenser is installed, degasses with oil pump, blows into N 2 , repeat 3 times. Inject the bubbling degassed toluene and deionized water with a needle, degas again with an oil pump, and blow in N 2 , repeat 3 times. The mixed solution was refluxed for 24 hours under heating in an oil bath. After cooling to room temperature, the reaction was quenched by adding saturated ammonium chloride solution, extracted with ethyl acetate (3×100 mL), the organic phase was washed with saturated ...

Embodiment 2

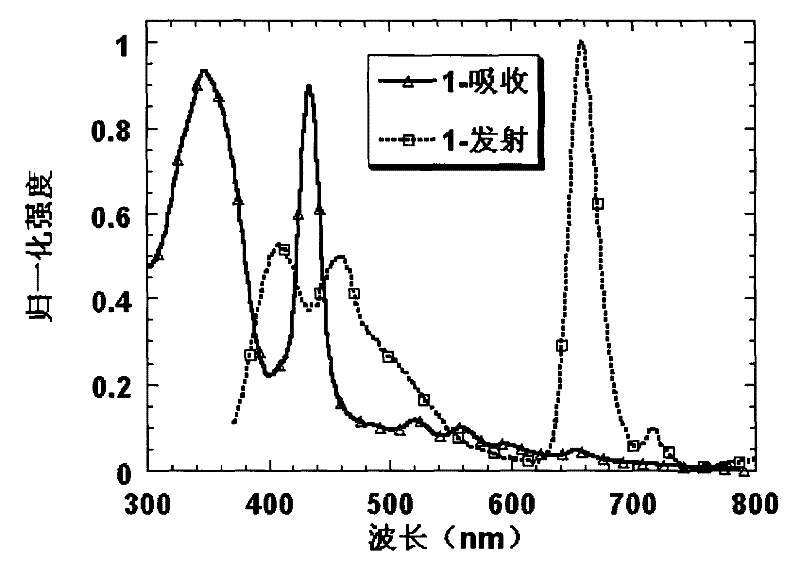

[0048] Embodiment 2: Preparation of compound 2 and its property determination

[0049] When preparing long oligomeric fluorene units, the synthesis method shown in the figure below is used:

[0050]

[0051] (1) Preparation of compound 6:

[0052] Compound 3 (1.0mmol), 1,3-propanediol (2.0mmol), p-toluenesulfonic acid (0.05mmol) were dissolved in toluene (50ml), and the mixed solution was heated and refluxed to TLC to detect that the raw material compound 3 had been consumed (about 4-6 hours), the reaction solution was left to room temperature, washed with deionized water, washed with saturated brine, dried over magnesium sulfate, and spin-dried to obtain a mixture purified by column chromatography (100-200 mesh silica gel, developer: petroleum ether / ethyl acetate=30: 1), product 6 is a white solid, yield: 92%.

[0053] 1 H NMR (CDCl 3 , 300Hz, ppm): δ 8.37-8.34 (Ar-H, 1H, d, J=8.4Hz), 8.24-8.17 (Ar-H, 2H, m,), 7.74-7.71 (Ar-H, 2H, d , J=8.4Hz), 7.65-7.50 (Ar-H, 8H, m)...

Embodiment 3

[0076] Embodiment 3: device making

[0077] The typical device manufacturing process of the present invention is as follows: ITO (indium tin oxide) glass is ultrasonicated for ten minutes with acetone, alkaline washing solution, pure water (twice), and isopropanol, and then treated with ozone plasmar for 5 minutes. The hole injection layer PEDOT (poly(3,4-ethylenedioxythiophene)) was spin-coated on the treated substrate to form a film with a thickness of 50 nm, and was heated in air at 160° C. for 6 minutes. A hole transport layer PVK (poly(9-vinylcarbazole)) (thickness 40 nm) was spin-coated thereon, and heated for 15 minutes in a nitrogen atmosphere. Then spin-coat the light-emitting layer (compound 1 or 2, thickness 60 nm), and heat for 15 minutes in a nitrogen atmosphere. Finally, Ba / Al (with a thickness of 4.5nm / 150nm) is vacuum evaporated to complete the device. The device structure is ITO / PEDOT(50nm) / Compound 1 or 2(60nm) / Ba(4.5nm) / Al(150nm) or ITO / PEDOT(50nm) / PVK(40nm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com