Patents

Literature

30results about How to "Adjust fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

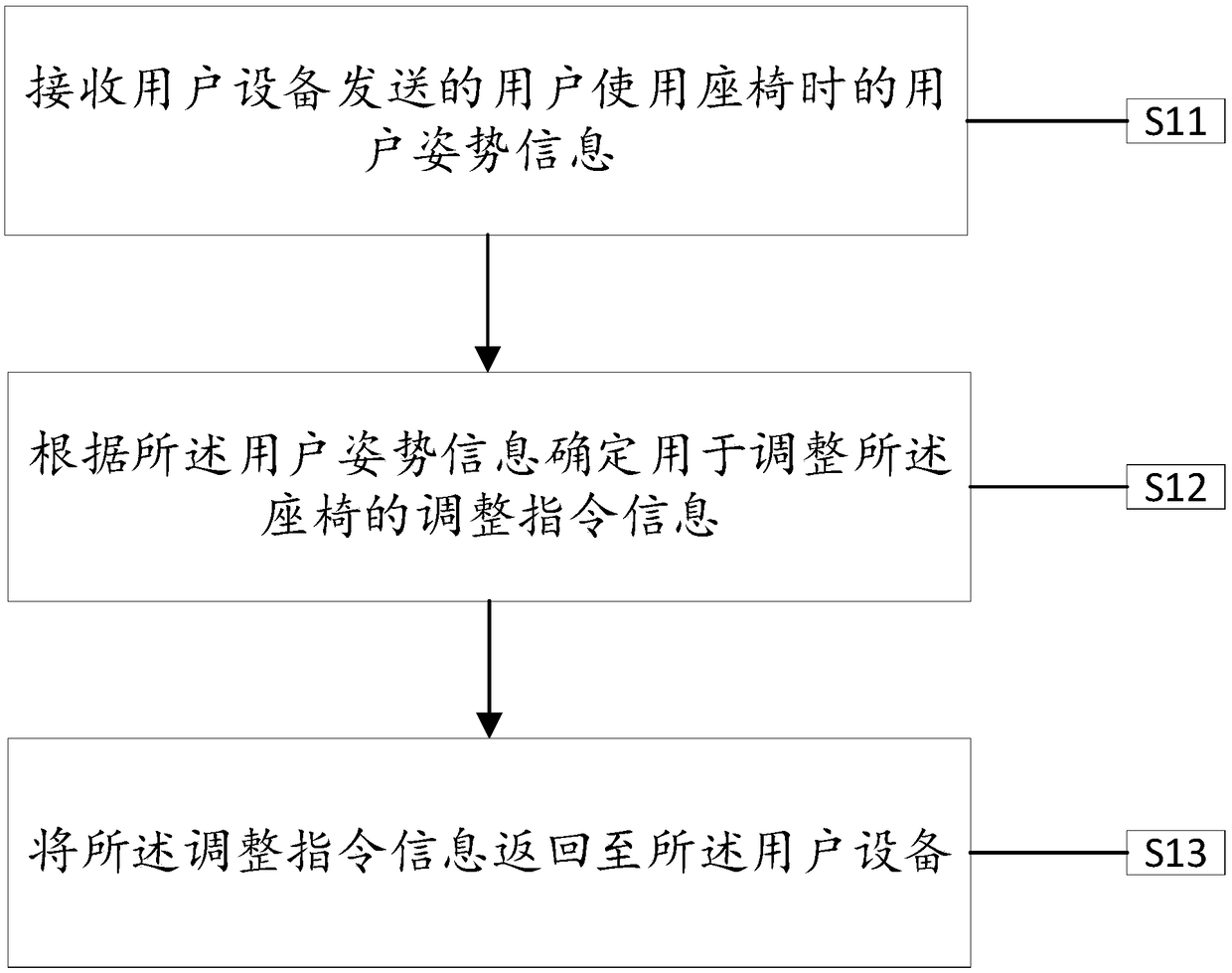

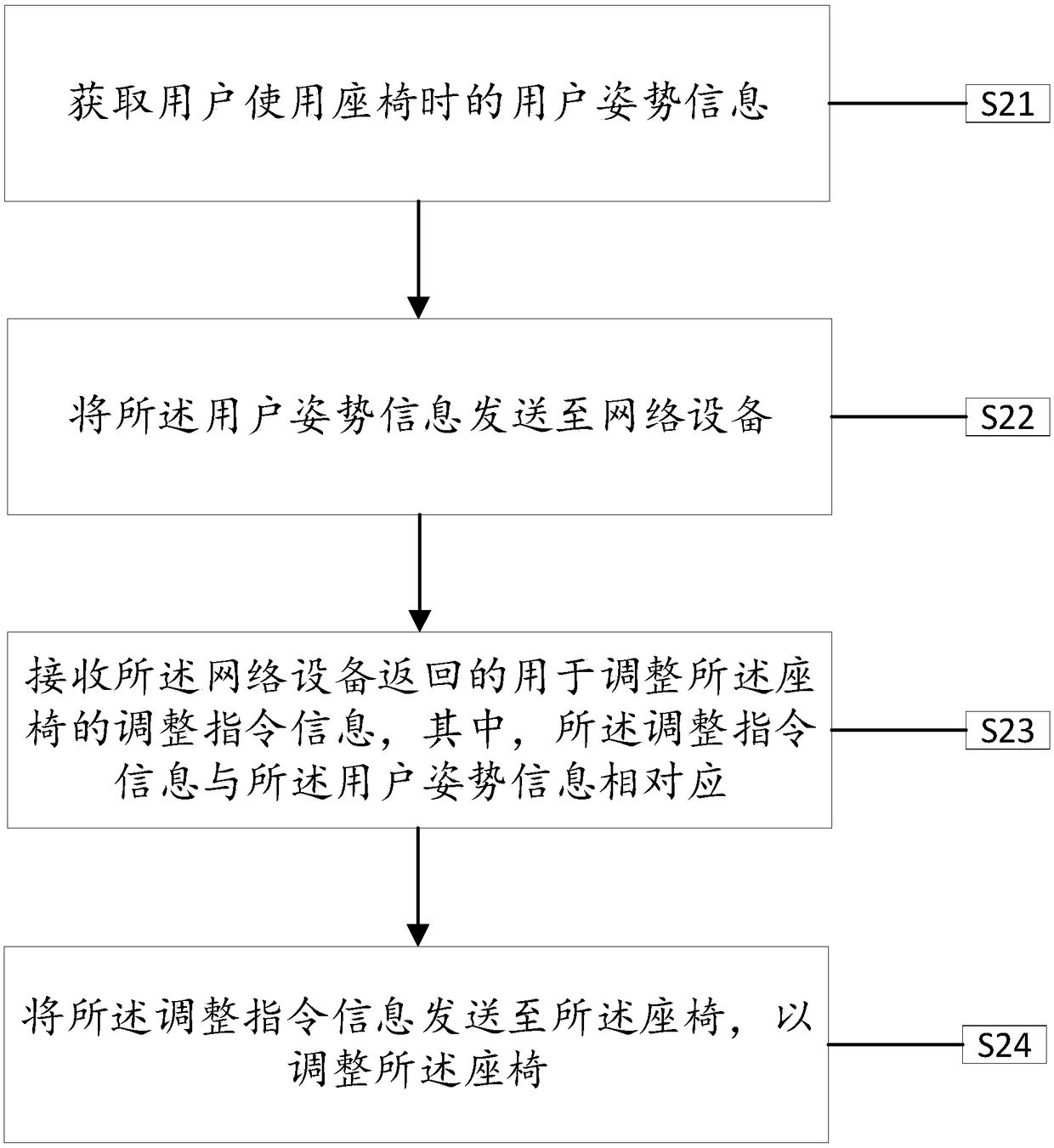

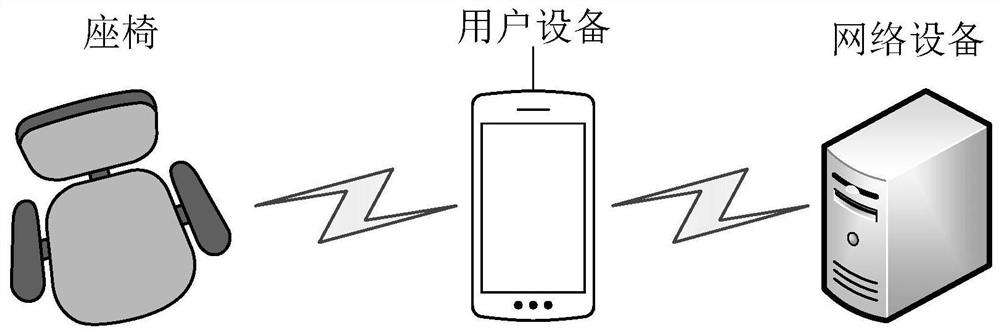

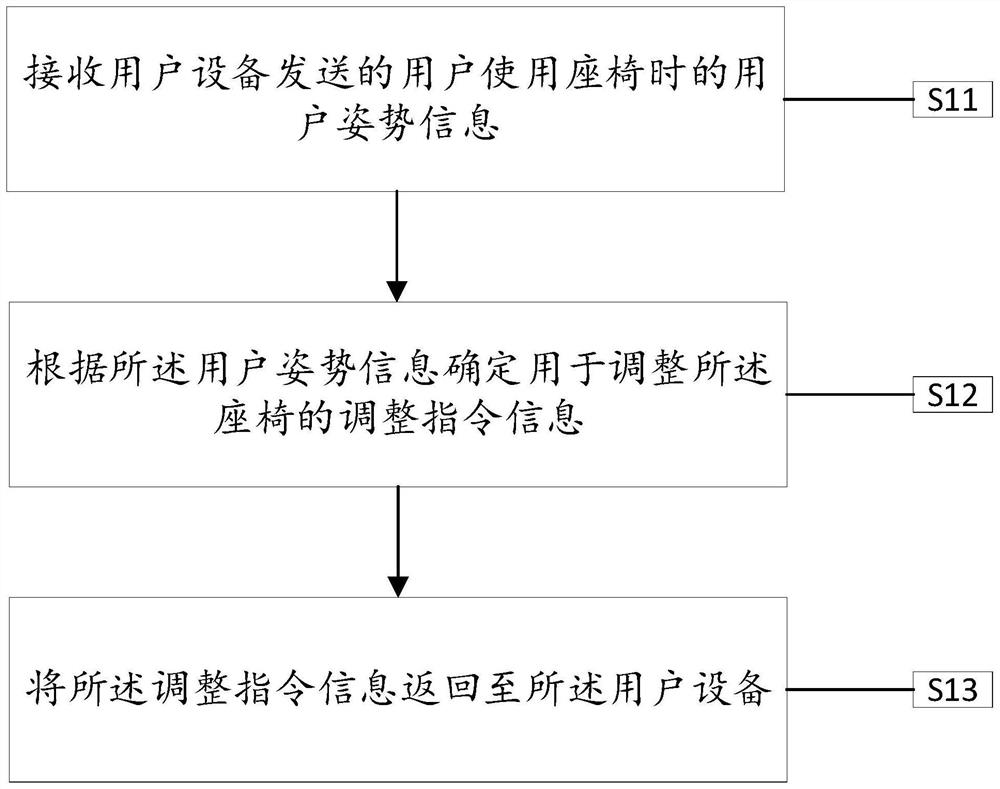

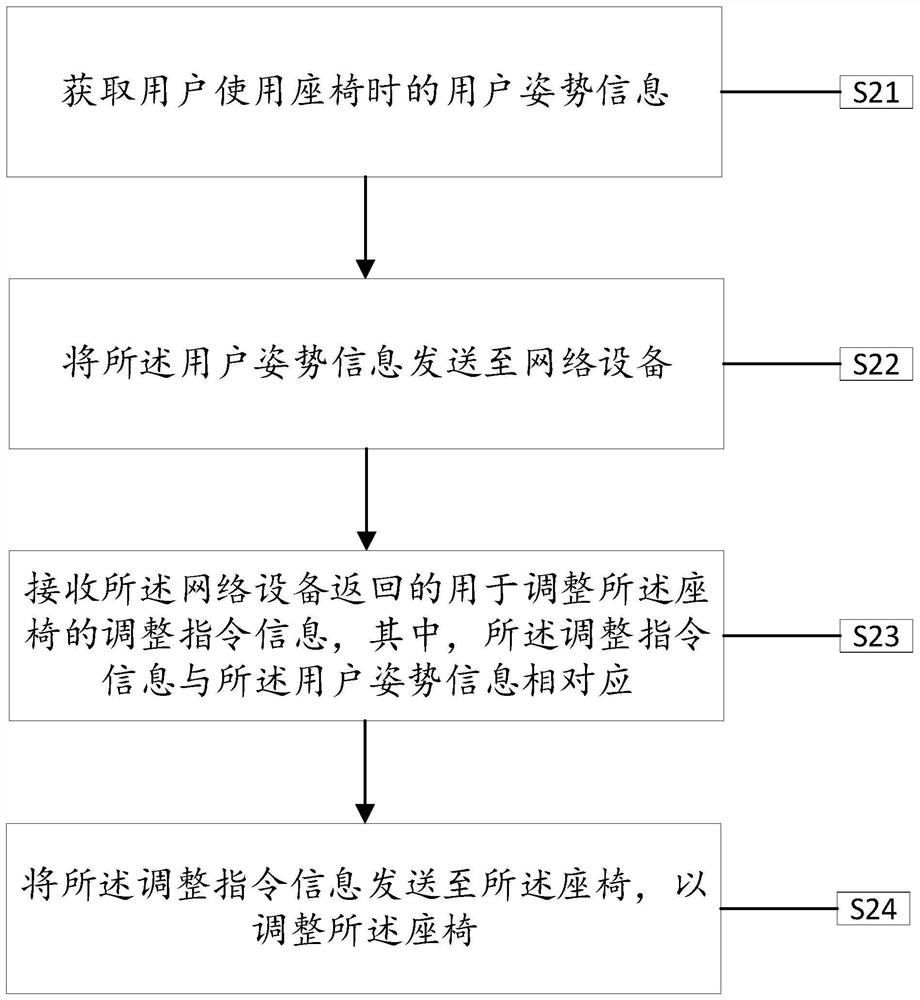

Method and equipment for adjusting user seat

ActiveCN108616585AEasy to adjustImprove user experienceStoolsTransmissionPostural orientationComputer science

The invention aims to provide a method for adjusting a user seat, wherein the method comprises the steps of receiving user posture information which is transmitted by user equipment in using the seatby a user; determining adjusting instruction information for adjusting the seat according to the user posture information; and returning the adjusting instruction information to the user equipment. According to the method of the invention, the user gesture information in using the seat by the user is acquired through the user equipment. A server determines the corresponding adjusting instruction information according to the user gesture information which is transmitted by the user equipment, wherein the adjusting instruction information is used for adjusting the seat which is used by the user.According to the method of the invention, the user gesture information can be acquired in real time, the seat is corresponding adjusted according to the user gesture change so that the seat can always supply optimal supporting and protection when the user uses the seat; and furthermore the seat is adjusted based on an automatic acquisition process of a sensor; and the adjusting process optimizesthe tedious adjusting operation of the user, thereby greatly improving user experience.

Owner:SHANGHAI CHENGTAN NETWORK TECH CO LTD

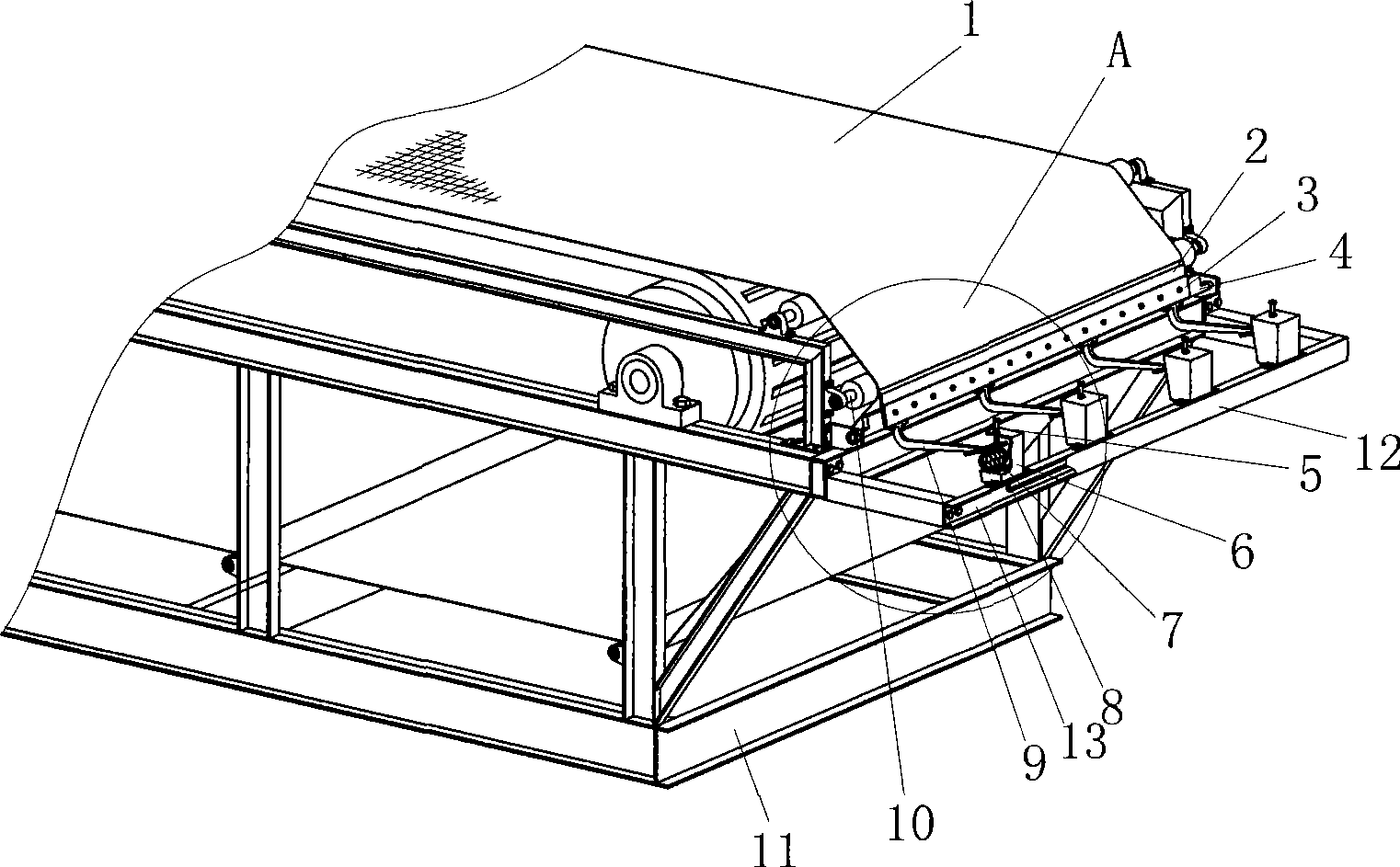

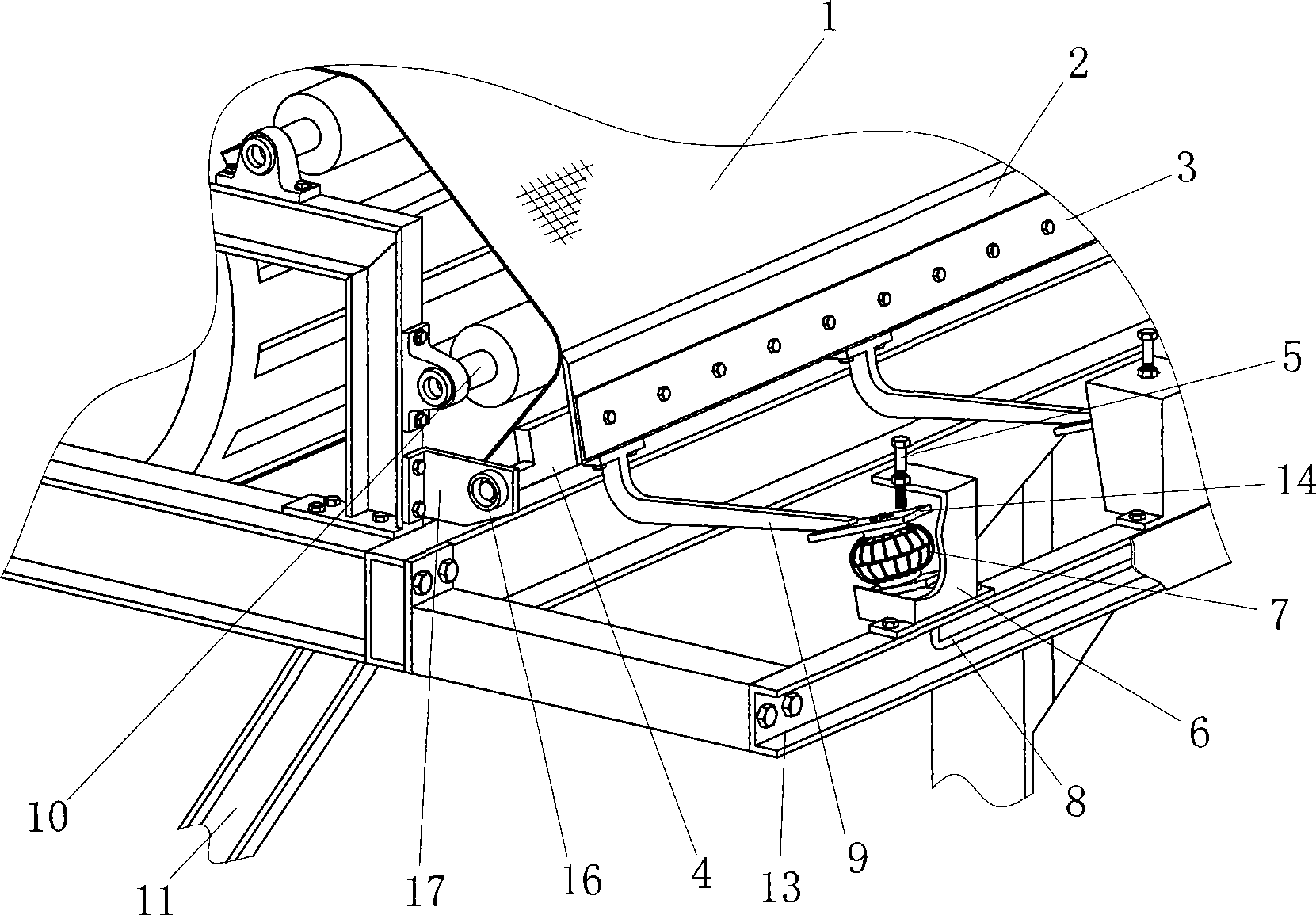

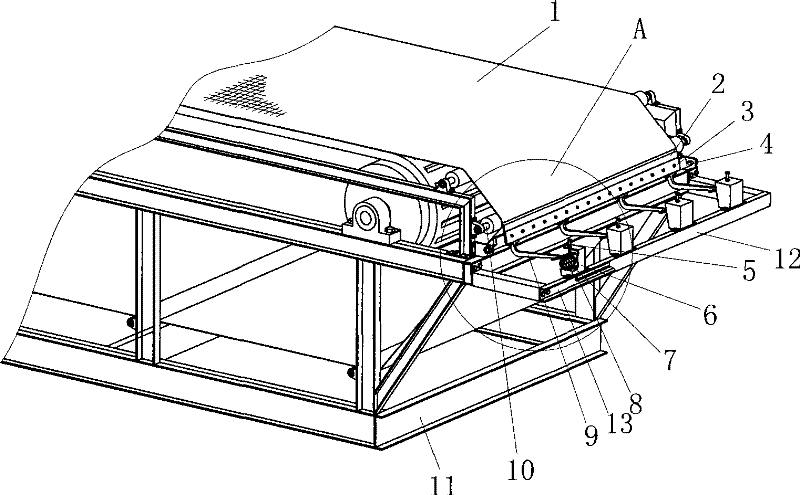

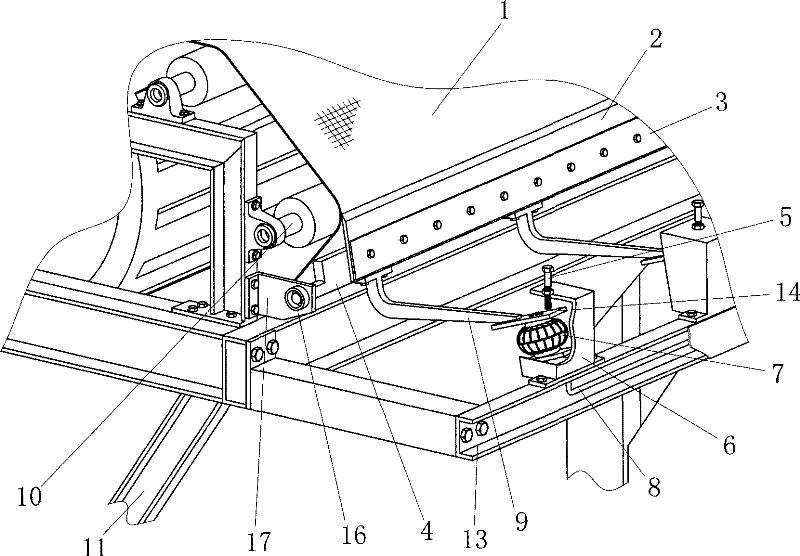

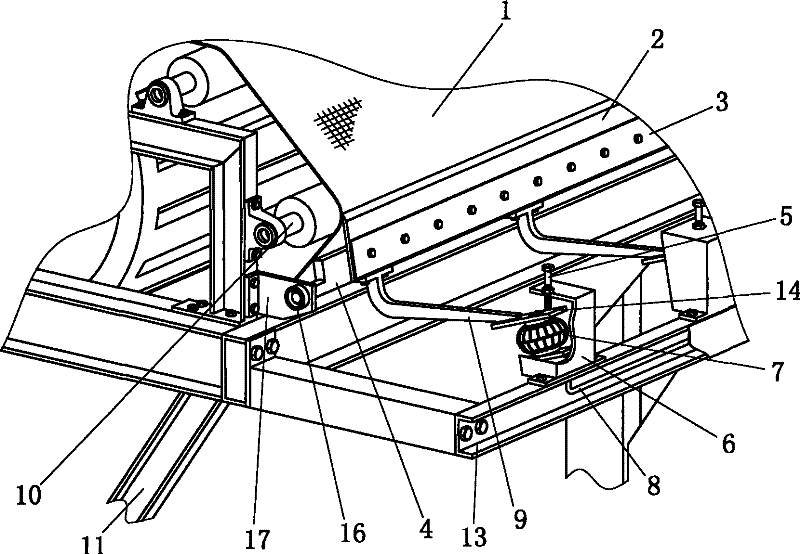

Rubber belt type vacuum filter discharge device

InactiveCN101485943AApplicable dischargeAdaptableMoving filtering element filtersFiltrationInlet pressure

The invention relates to a scraper discharging device, in particular to the scraper discharging device of filtration fabric of a rubber belt type vacuum filter. The scraper discharging device comprises a scraper support saddle and a scraper bracket arranged on the scraper support saddle, wherein the scraper bracket is pivoted with a scraper by a bearing; the scraper comprises a scraper body and a squeeze plate for squeezing the scraper body; the scraper body and the squeeze plate are positioned at the two sides of the bearing respectively; one ends of a plurality of bent levers are fixedly connected with the squeeze plate of the scraper; and the other ends of the bend levers are linked with an air bag. The output force of the air bag can be controlled by adjusting inlet pressure through a pressure regulating valve so as to conveniently adjust condition of the action of the scraper and a discharging roll and avoid damage to the filtration fabric.

Owner:湖州旺能环保科技有限公司

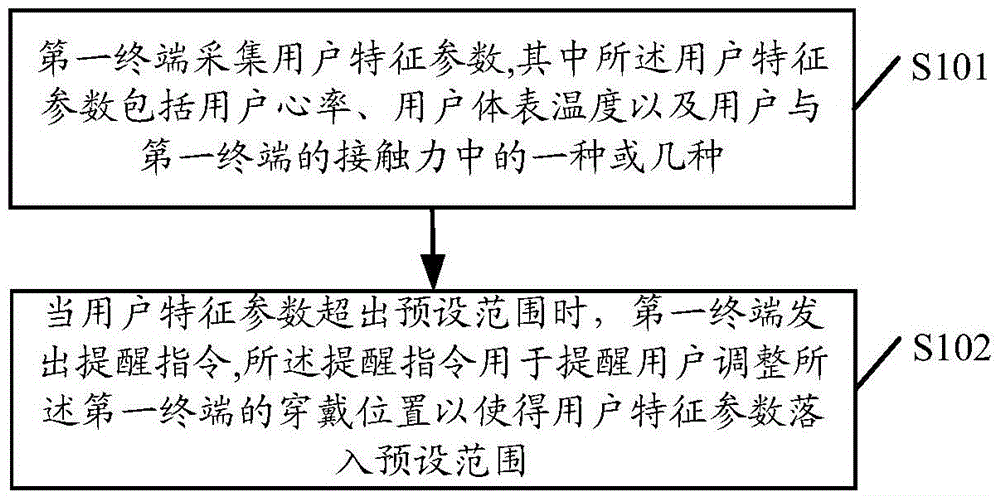

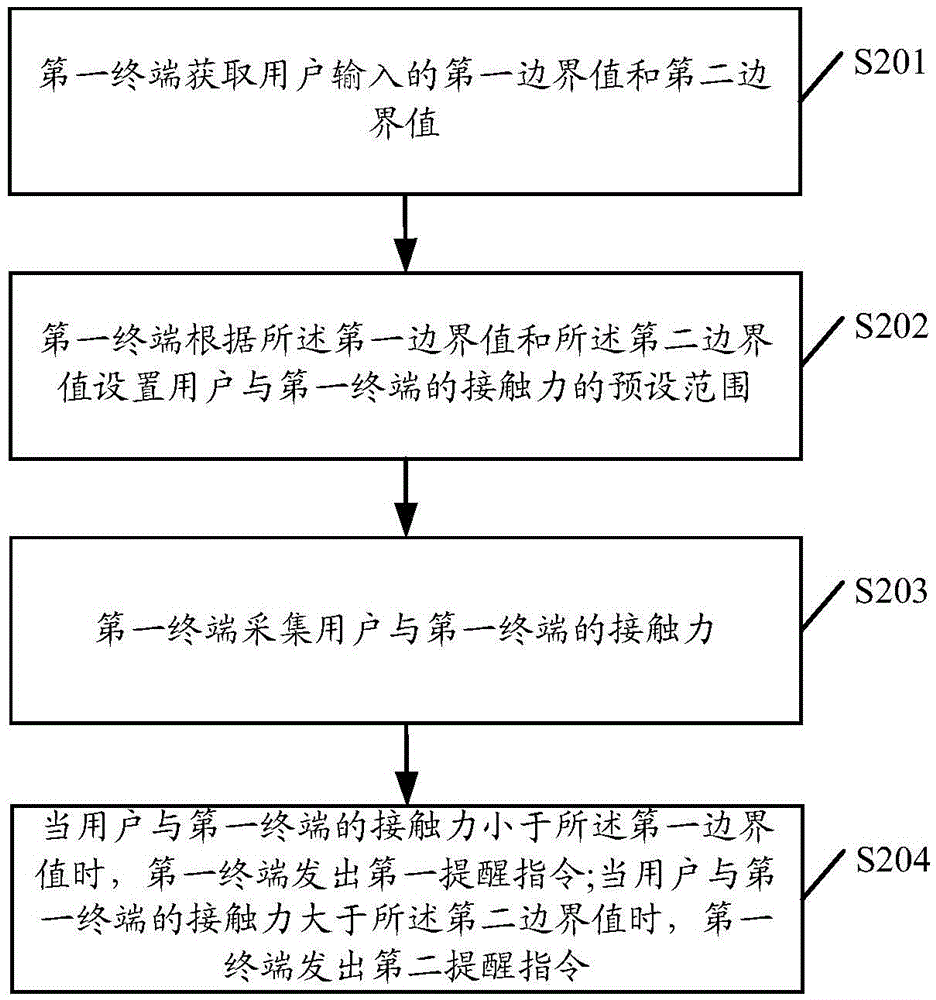

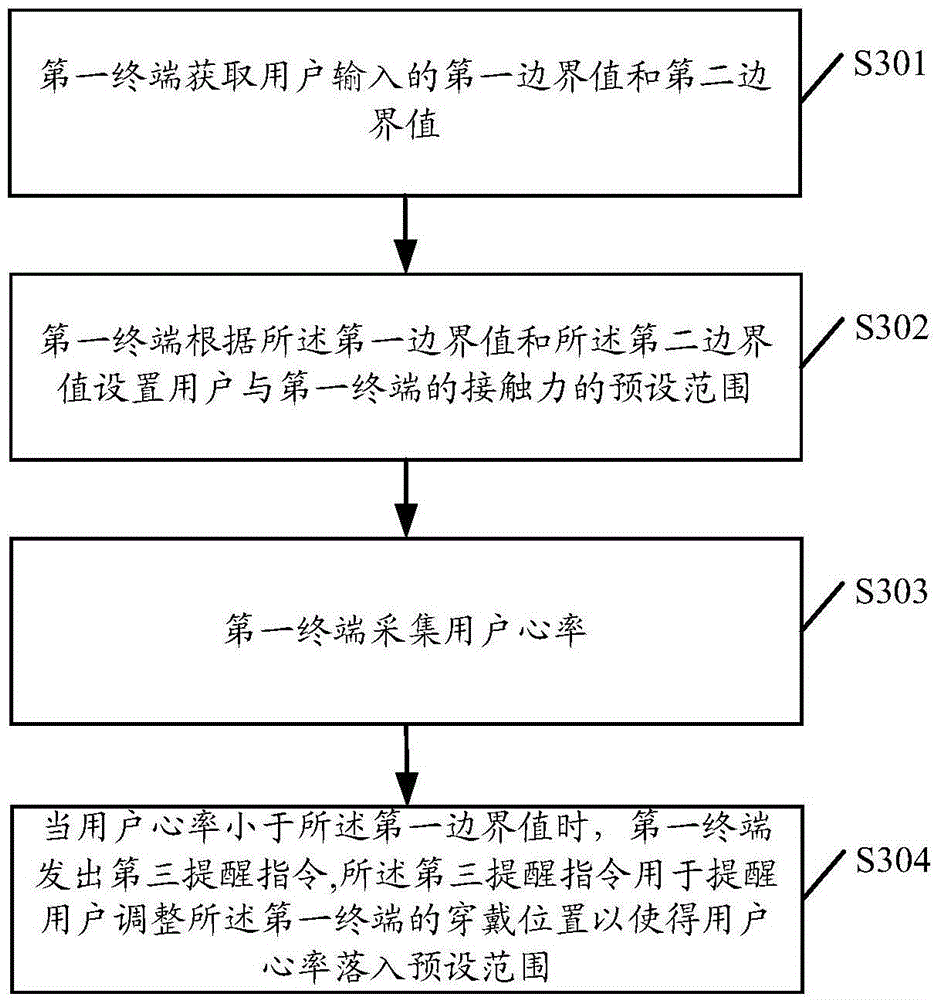

Terminal adjustment reminding method and smartband

InactiveCN105533940AAdjust fitTimely detection of wearing incorrectlyBraceletsSensorsContact forceComputer science

The invention discloses a terminal adjustment reminding method and a smartband. The method comprises the following steps: collecting characteristic parameters of user by a first terminal, wherein the characteristic parameters of user comprise one or more of heart rate of user, shell temperature of user, and contact force between a user and the first terminal; and when the characteristic parameters of user exceed a preset range, sending a reminding command by the first terminal, wherein the reminding command reminds the user to adjust the position of the first terminal so as to make the characteristic parameters fall into the preset range. The provided method can make a user find that a smartband is on an incorrect position in time so the user can adjust the position of the smartband.

Owner:HESVIT HEALTH TECH CO LTD

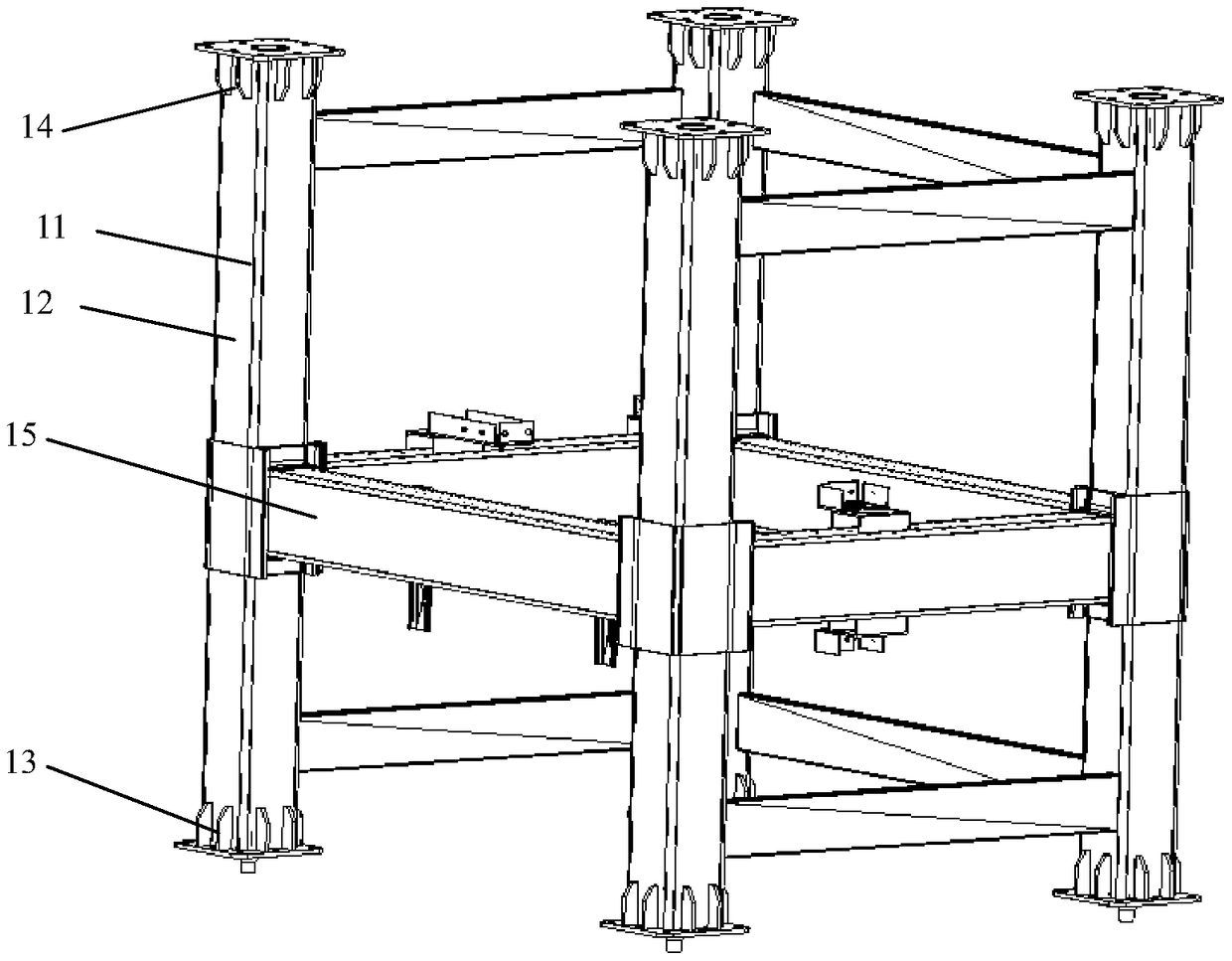

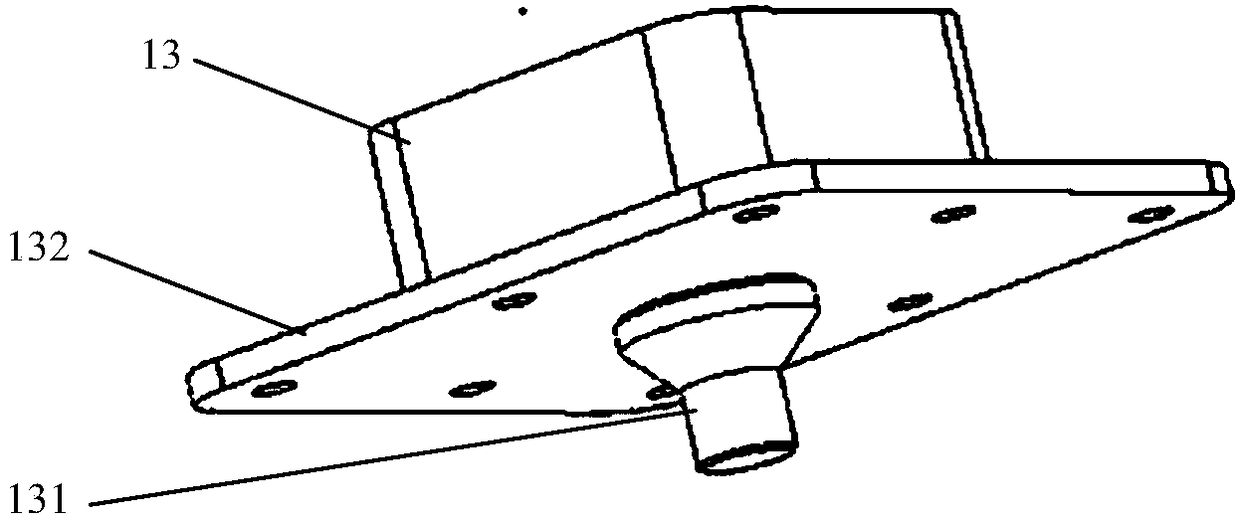

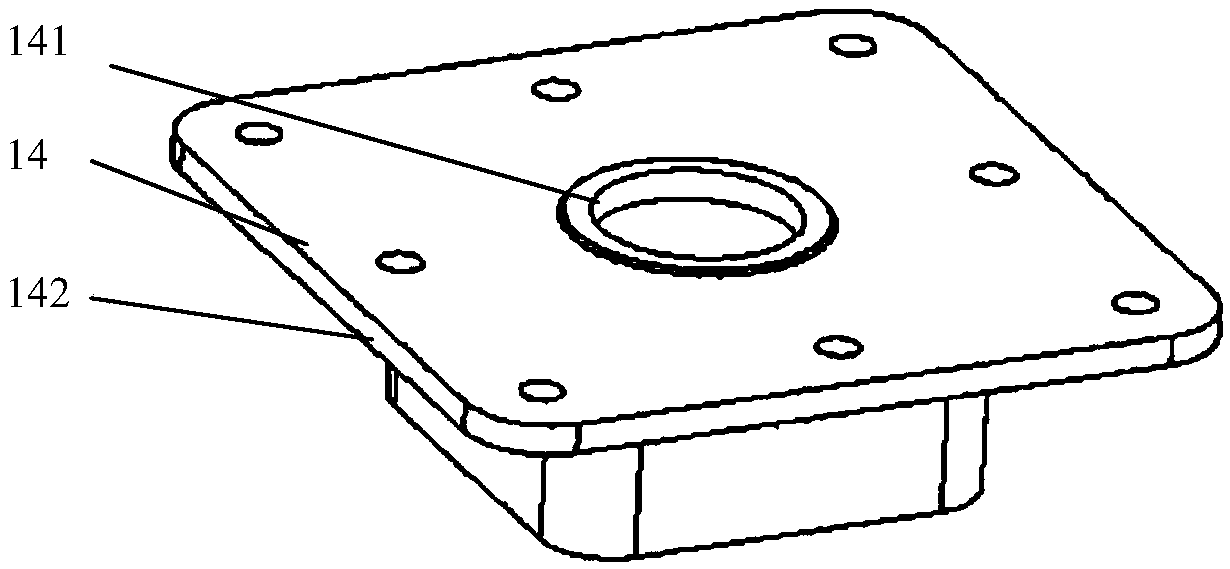

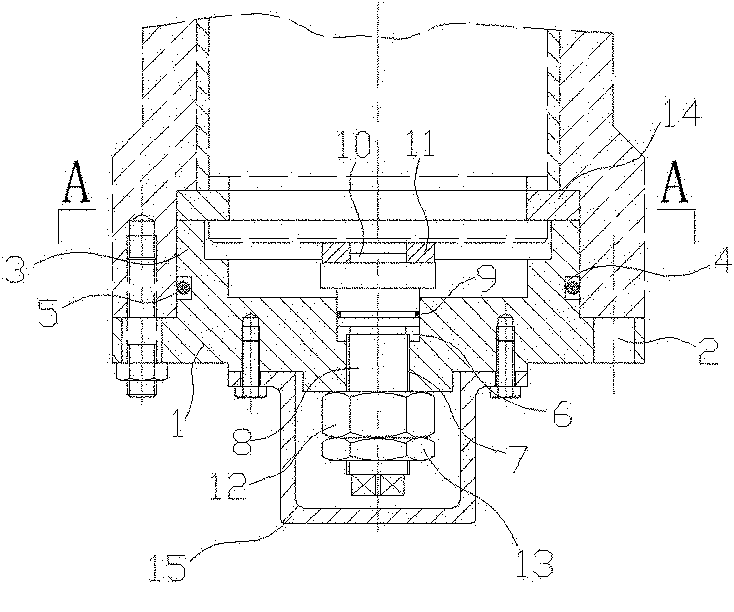

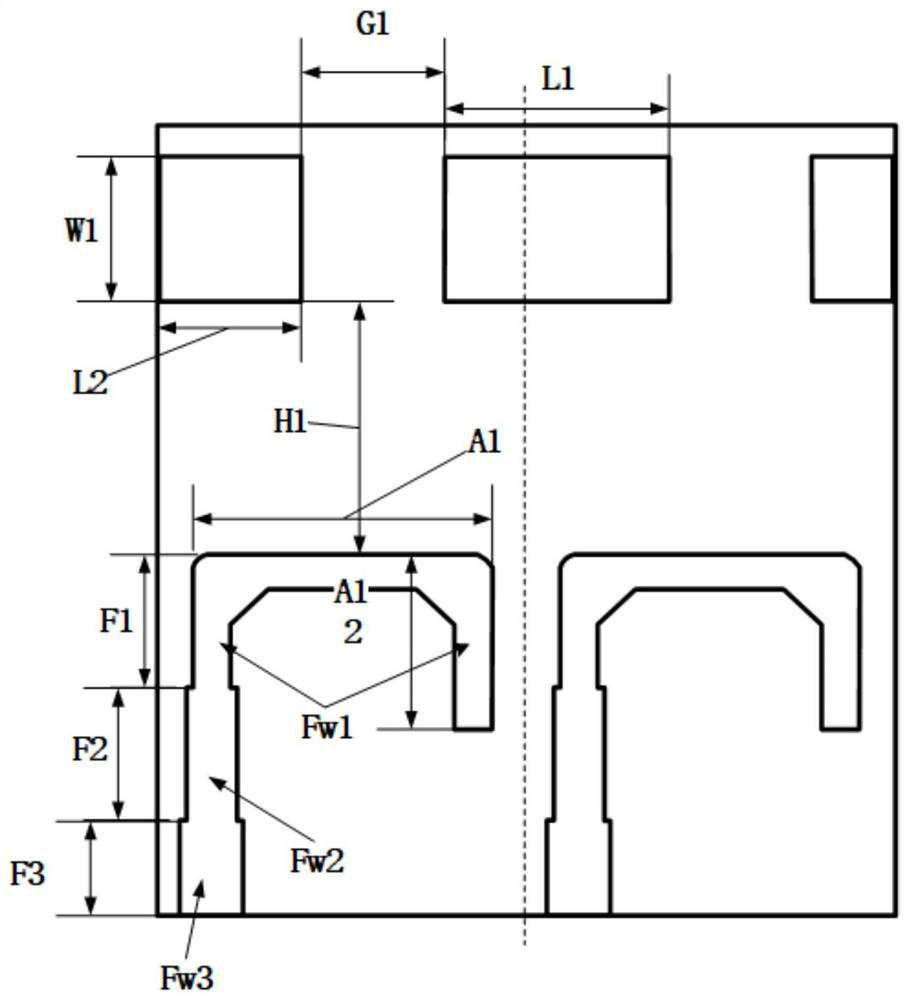

Additionally arranged elevator shaft structure and construction method thereof

InactiveCN109138364ARealize segmented constructionAdjust fitBuilding repairsVertical ductsBuilding construction

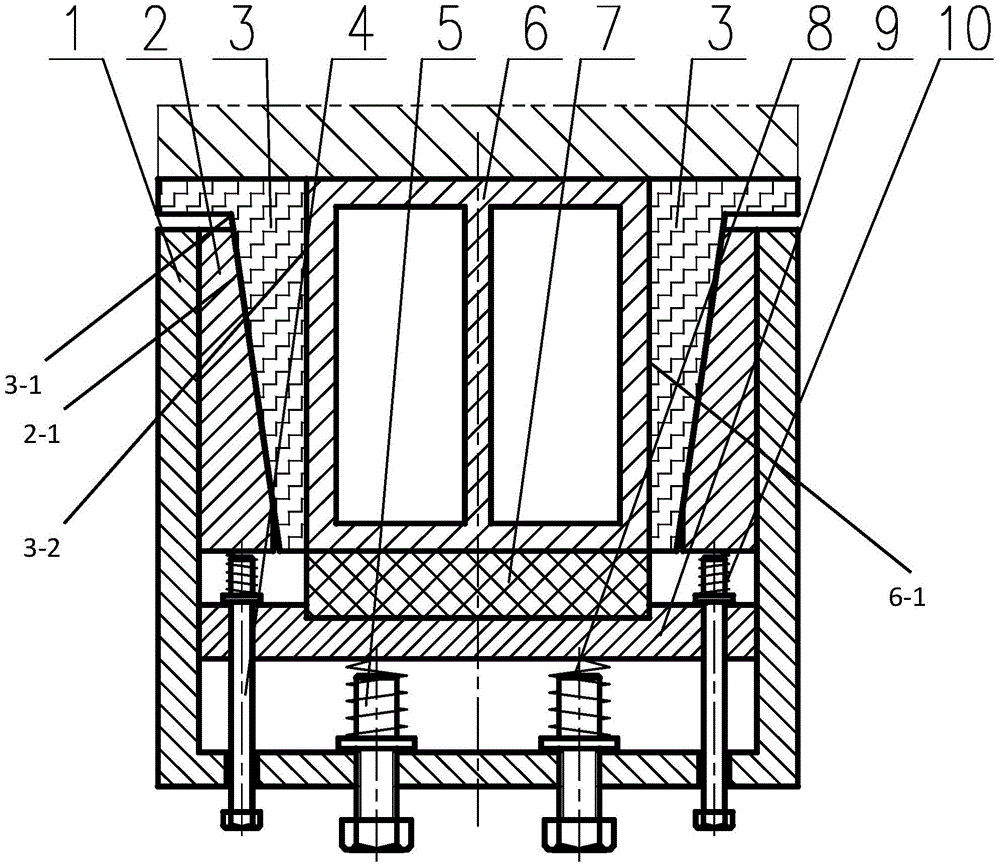

The invention discloses an additionally arranged elevator shaft structure and a construction method thereof. The additionally arranged elevator shaft structure comprises a plurality of shaft segmentswhich are spliced to each other, each shaft segment comprises a plurality of vertical columns, and the vertical columns of every two adjacent shaft segments are spliced to each other through interfaces. Each interface includes a first interface fixedly connected to one vertical column and a second interface fixedly connected to the other vertical column, one of the first interfaces and the secondinterfaces is provided with a guiding member, and the other of the first interfaces and the second interfaces is provided with a limiting member matched with the guiding member. The first interfaces and the second interfaces are further provided with mutually matched fixing members. Through the arrangement of the first interfaces and the second interfaces, the additionally arranged elevator shaftstructure and the construction method thereof can realize segmentation construction of an elevator shaft, and at the same time, the degree of coincidence and verticality of the shaft at the upper andlower ends are adjustable during the construction process.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

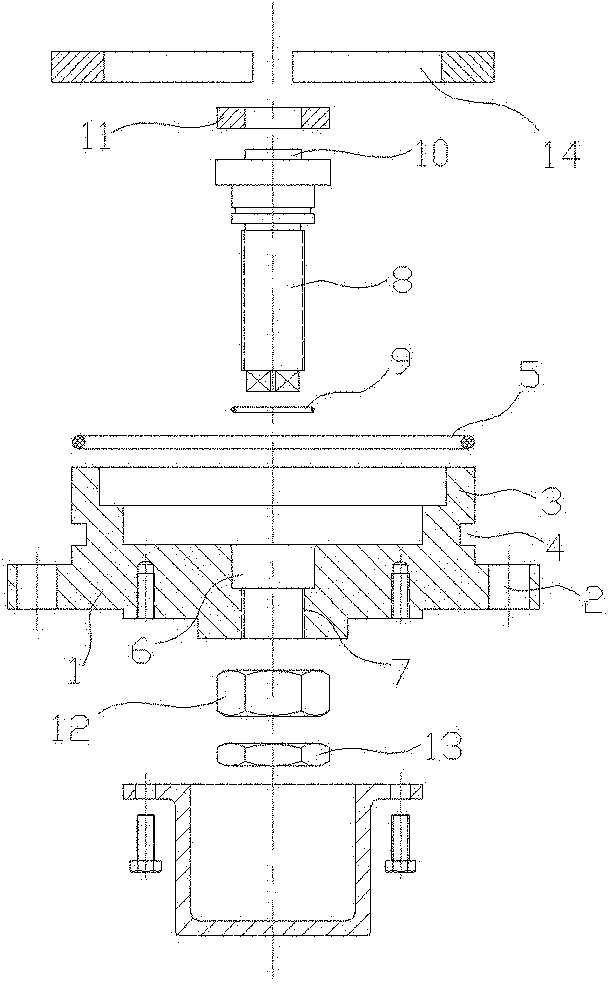

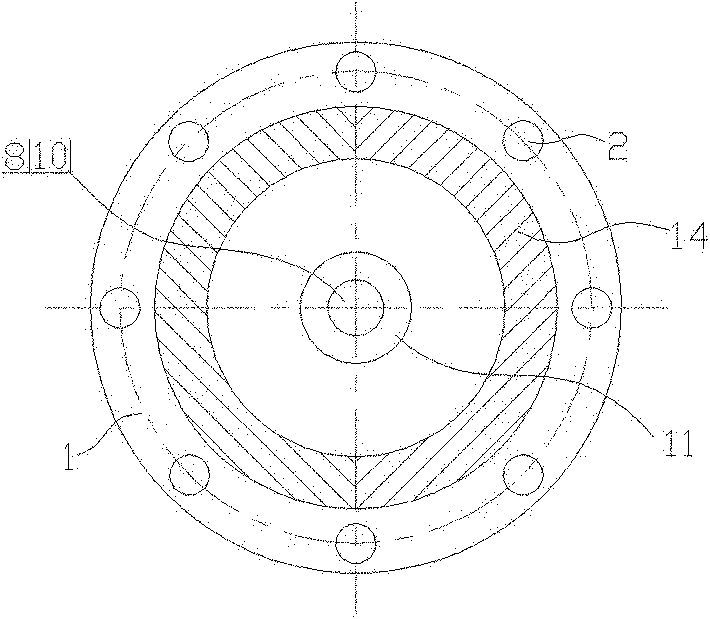

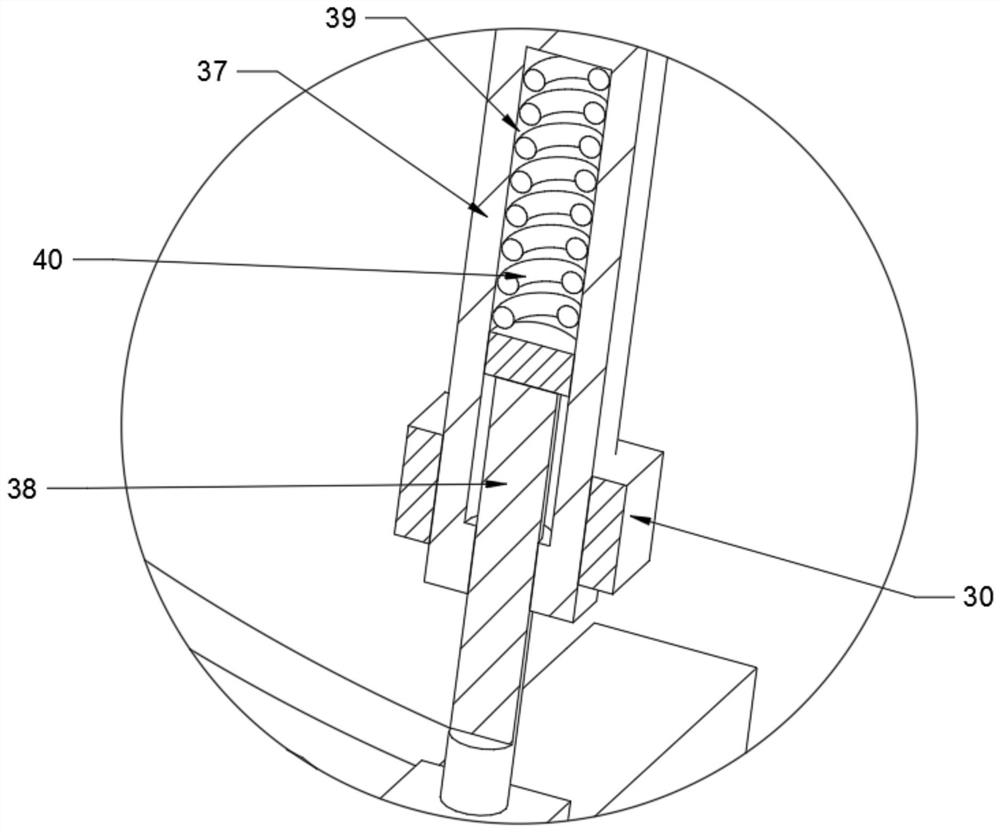

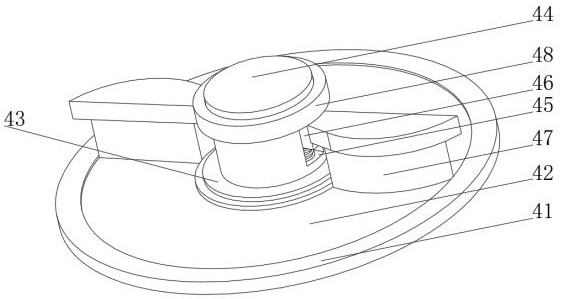

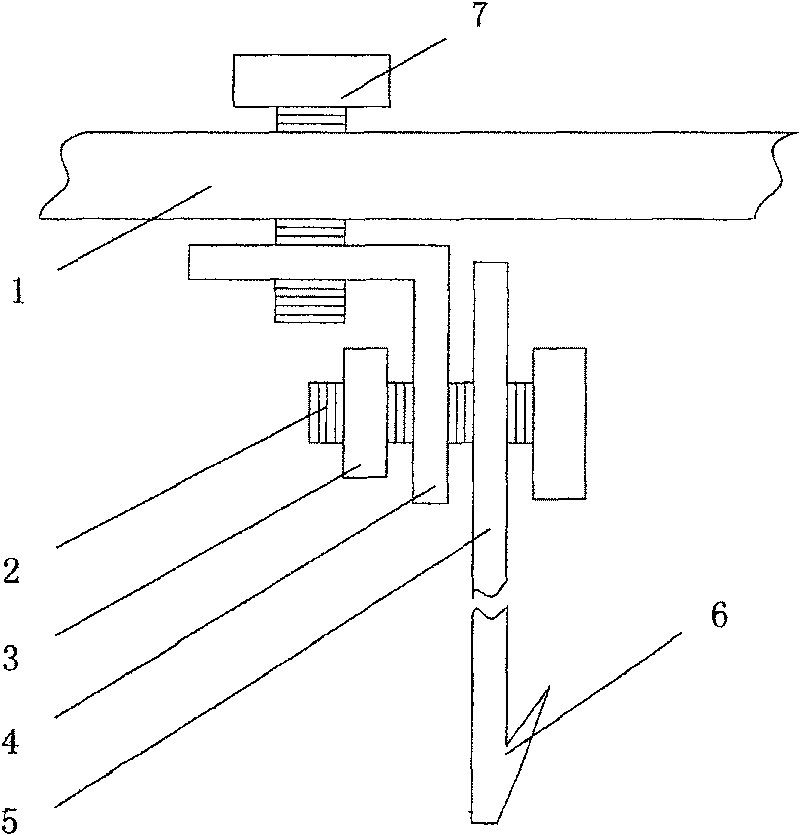

Axial adjusting device of butterfly valve shaft

The invention discloses an axial adjusting device of a butterfly valve shaft. Axial round holes are uniformly distributed in the outer circumference of a round end cover; the upper part of the end cover is connected with a convex cylinder; a sealing groove is arranged on the cylinder of the end cover; an adjusting screw is screwed in the center of the end cover; a sealing ring is arranged between the adjusting screw and the round hole; a round protrusion is arranged at the upper end of the adjusting screw; an annular friction pad is sleeved on the round protrusion; a fastening nut and a binding nut are sequentially screwed at the lower end of the adjusting screw; a split ring comprising two half rings is supported against and connected with the upper end of the cylinder of the end cover; and a protective cover connected by screws is arranged at the end face of the end cover. In the invention, the rotatable adjusting screw is arranged on the end cover; the friction pad is arranged at the upper end of the adjusting screw; after the butterfly valve is assembled, the friction pad is closely supported against the lower end face of the valve shaft; the valve shaft can continuously move along the axial direction conveniently by rotating the adjusting screw; and when the butterfly valve is assembled, debugged and overhauled, the fit between the sealing ring of the valve body and a sealing ring of a butterfly plate can be conveniently adjusted, so that the fit precision between the sealing ring of the valve body and the sealing ring of the butterfly plate is higher.

Owner:LIAONING NENGFA WEIYE ENERGY TECH CO LTD

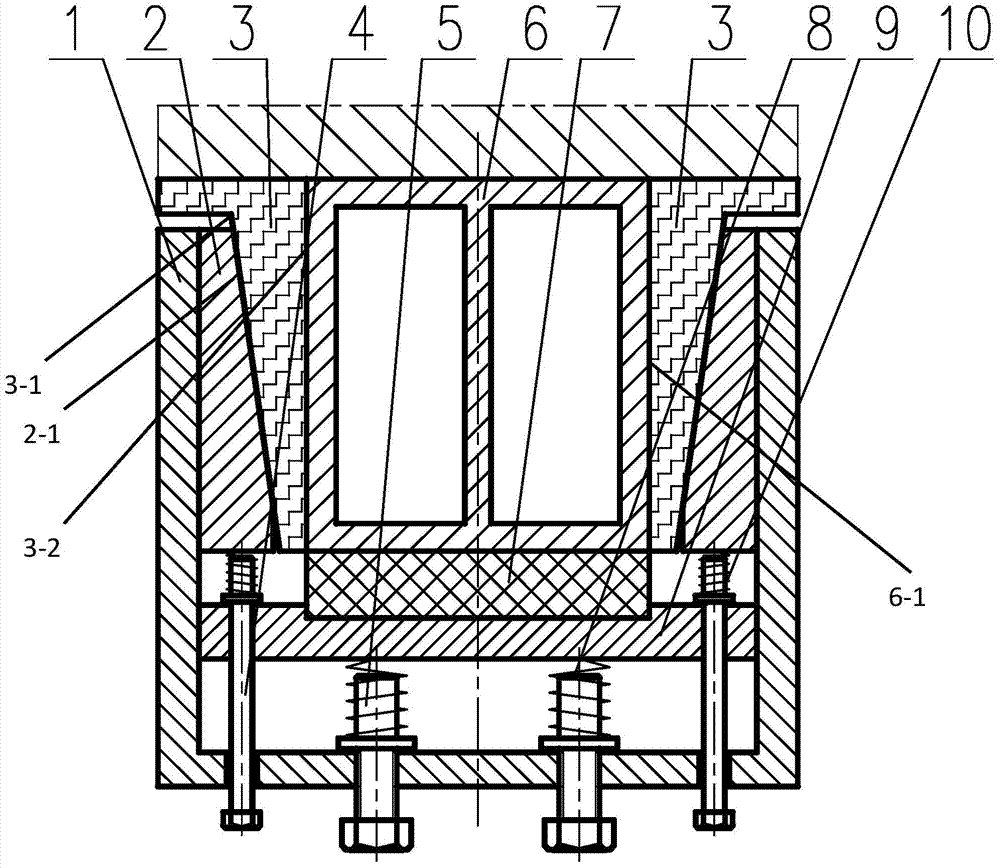

Multi-direction adjustable sealing device used for carling air passing chamber of grate cooler

ActiveCN103884195AClear structureEasy to operateEngine sealsHandling discharged materialEngineeringMechanical engineering

The invention relates to a multi-direction adjustable sealing device used for a carling air passing chamber of a grate cooler. A retainer spring I is installed on a short screw in a sleeved mode to exert pressing force on an adjusting plate, wherein the short screw penetrates through the bottom of a peripheral frame. A long screw penetrates through the bottom of the peripheral frame and the adjusting plate, and a retainer spring II is installed on the long screw in a sleeved mode to exert pressing force on a wedge-shaped block. A rectangular sealing piece is located on the adjusting plate and is attached with the lower surface of a movable part. The inclined surface of a wedge-shaped sealing piece is attached to the inclined surface of the wedge-shaped block, and the vertical surface of the wedge-shaped sealing piece is attached to the lateral surface of the movable part. The peripheral frame is located outside the wedge-shaped block, the wedge-shaped sealing piece, the movable part, the rectangular sealing piece and the adjusting plate. The multi-direction adjustable sealing device is used for realizing multi-direction sealing of the movable part, the adjusting screws are used for adjusting the pressing force of the retainer springs so as to enable the sealing piece and the movable part to be tightly attached, and therefore the effect of sealing the movable part is realized.

Owner:NANJING KISEN INT ENG

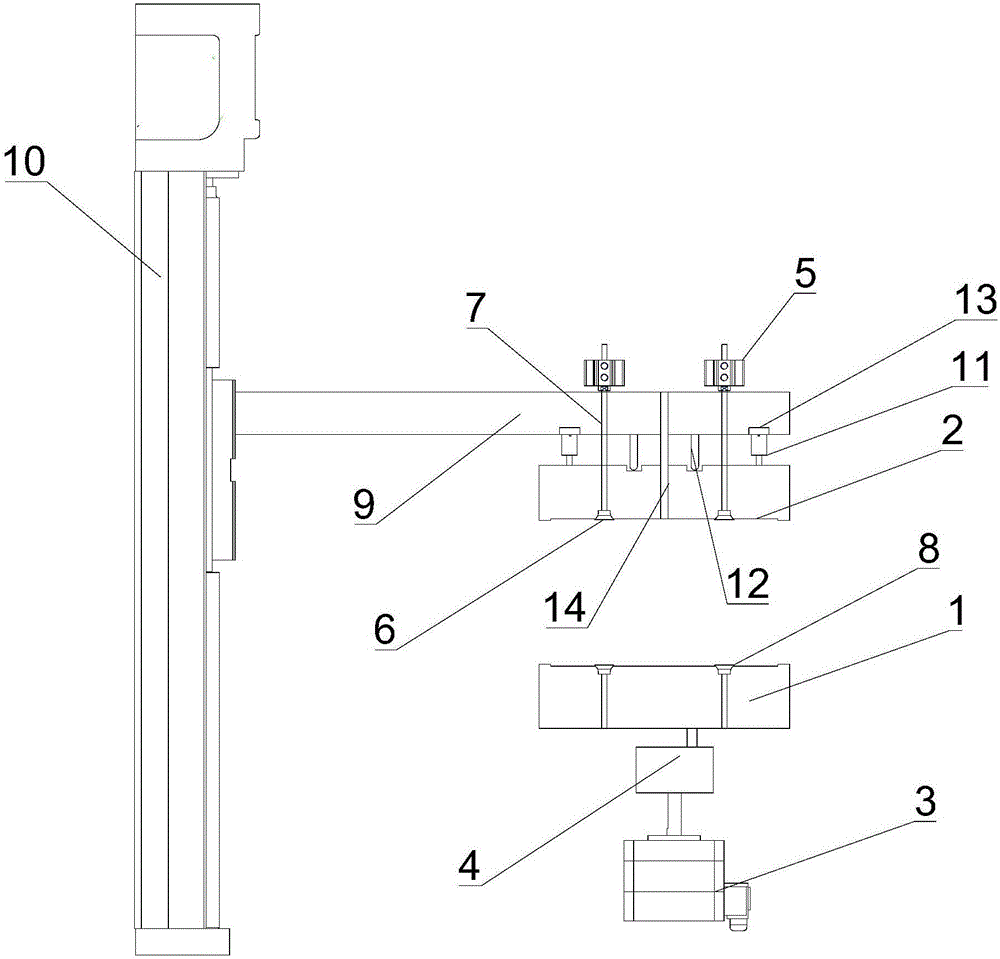

Automatic grinding device and grinding method

ActiveCN106625102AConsistent hardnessHigh grinding efficiencyEdge grinding machinesGrinding work supportsCeramicEngineering

The invention discloses an automatic grinding device and a grinding method. The device comprises a first jig and a second jig which are arranged oppositely and can rotate relatively; workpieces to be ground are fixed on the first jig and the second jig respectively, and molten slag surfaces of the workpieces to be ground are arranged oppositely. The device adopts the two jigs capable of rotating relatively and workpieces including ceramic and the like are arranged between the two jigs; the two jigs are controlled to rotate relatively so that the two workpieces are driven to rotate relatively; molten slag is removed by utilizing friction force between the two workpieces; the rigidity of materials of the workpieces is consistent, so that damages to the materials are not caused in a rubbing process; and the problems that the loss of a shovel plate and the materials are prone to being damaged in a traditional grinding process are solved by the device. By adopting the device and the method, two workpieces can be machined simultaneously, so that the grinding efficiency is high and the cost is low.

Owner:CHANGZHOU INNO MACHINING

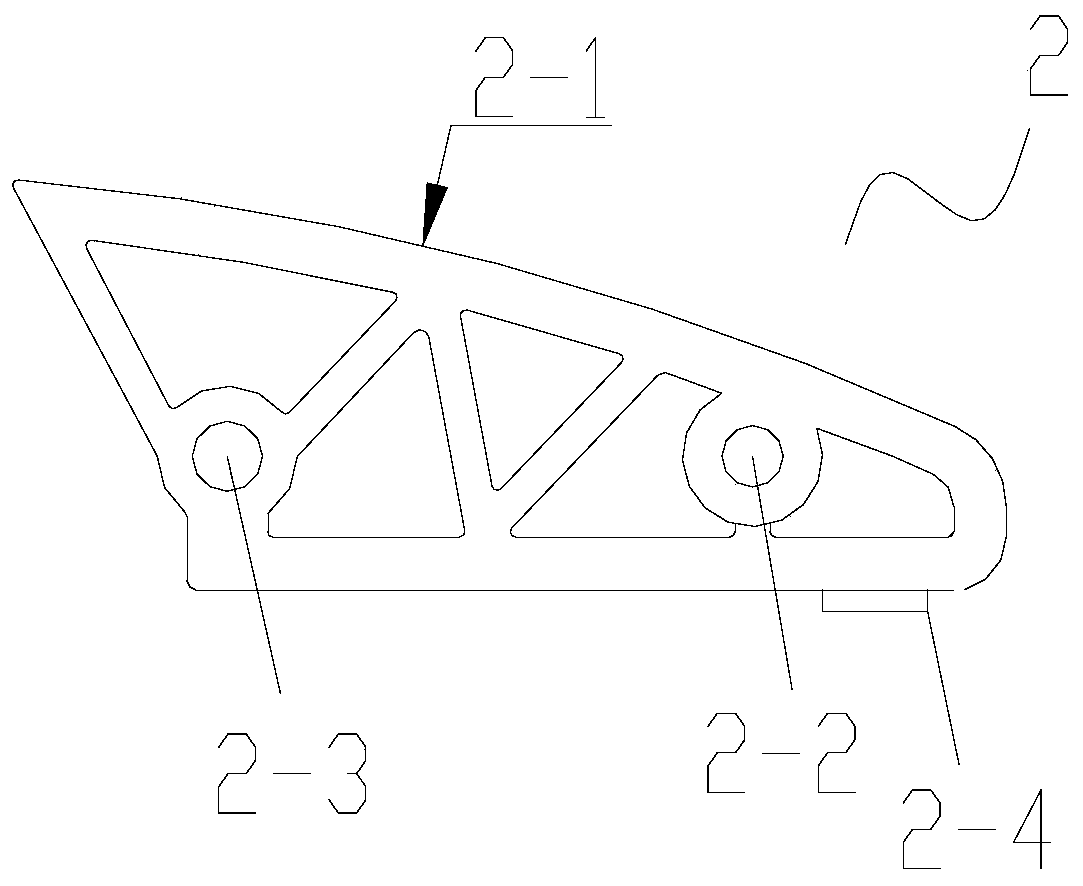

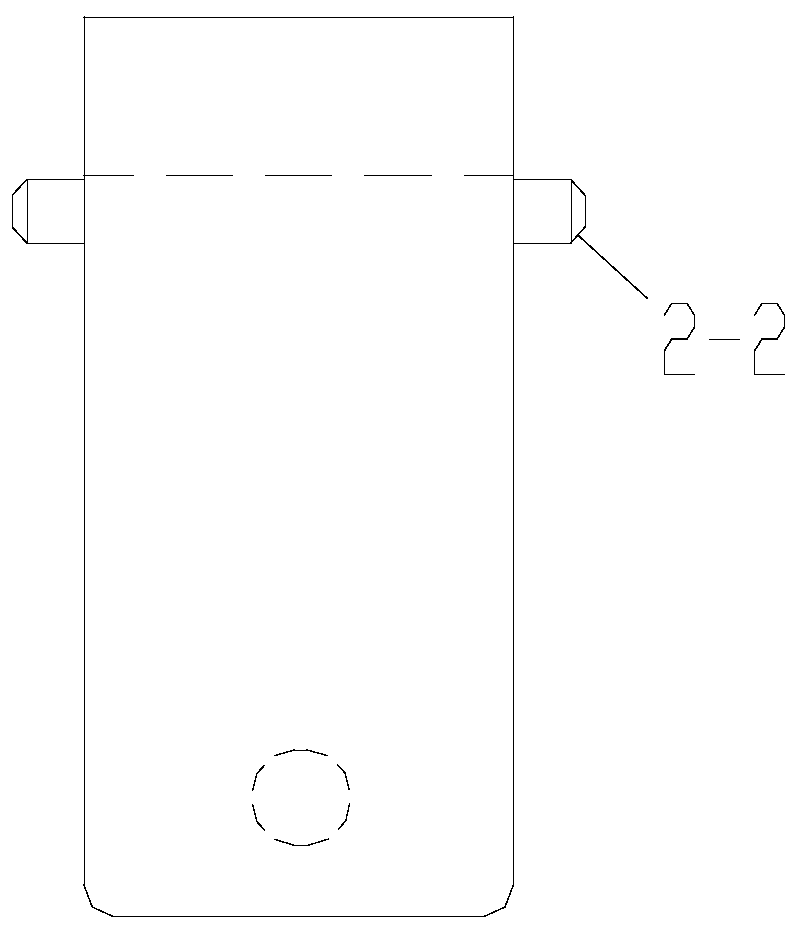

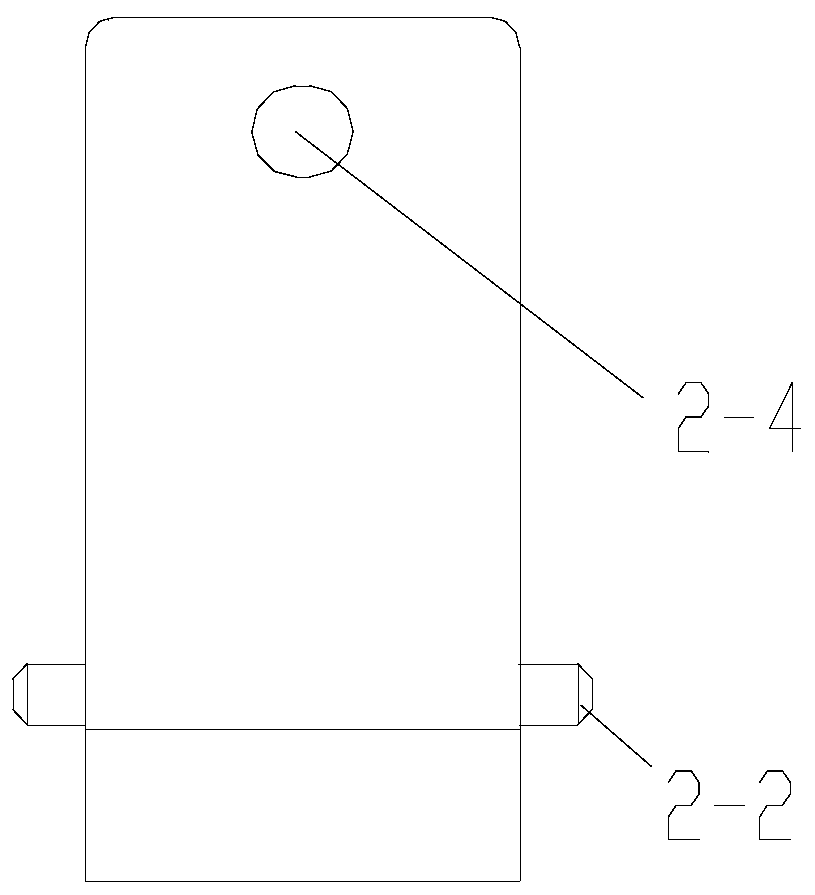

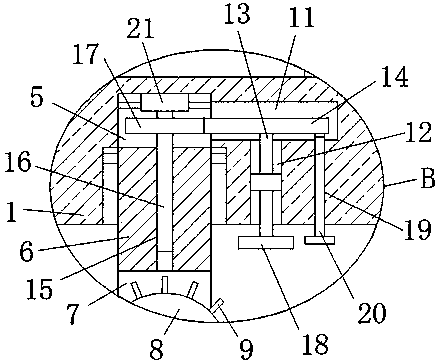

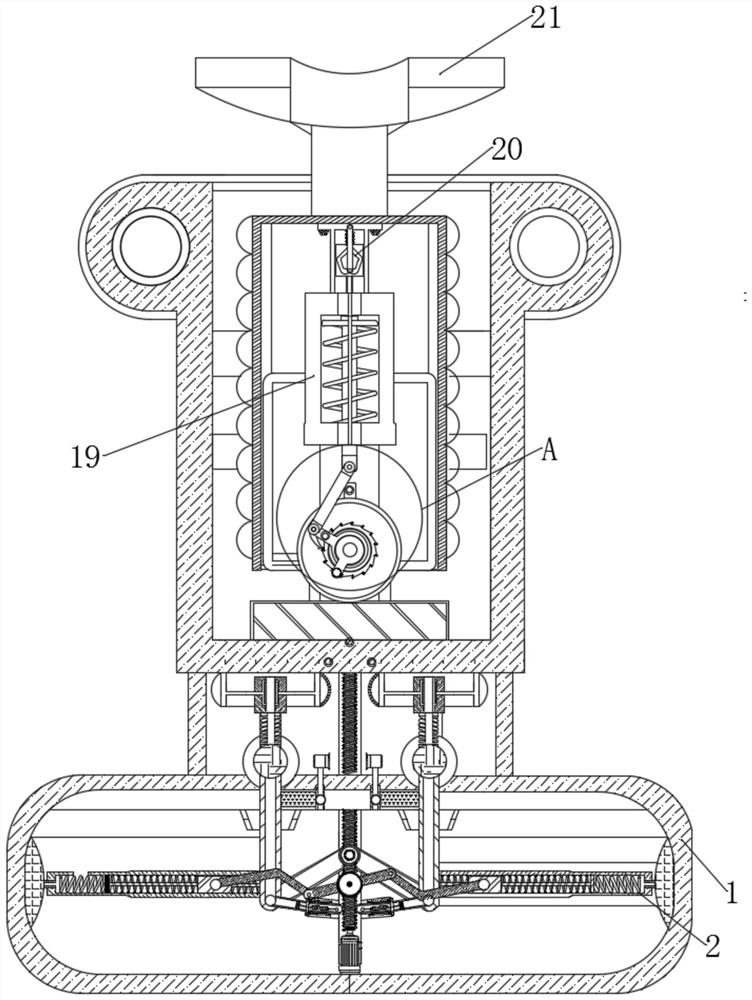

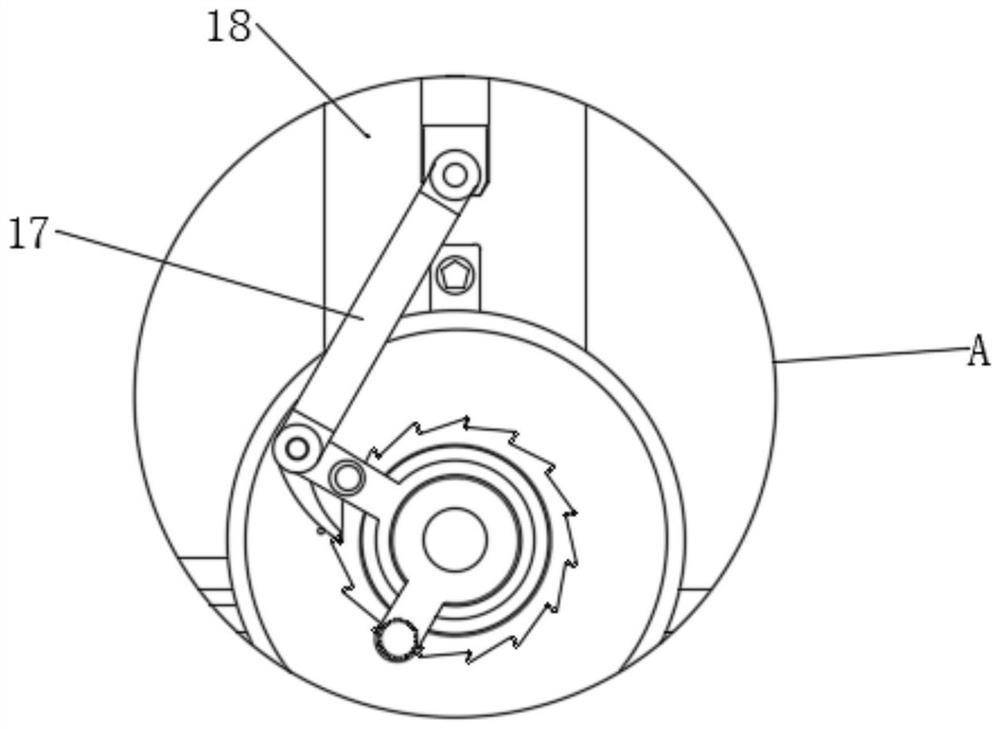

Sucker rod elevator

The invention discloses a sucker rod elevator comprising an oil pipe elevator and a fixed shaft. The fixed shaft penetrates through an axial hole of the oil pipe elevator from top to bottom. A fixed shaft clamping block is arranged in the oil pipe elevator. The fixed shaft clamping block is connected with a clamping block opening and closing power mechanism. The upper end of the fixed shaft is connected with a non-slip nut. A compression spring is arranged at the position, between the fixed shaft clamping mechanism and the non-slip nut, on the fixed shaft in a sleeving manner. The fixed shaftis of a steel pipe structure with an internal axial cavity. A supporting baffle is arranged on the lower portion of the oil pipe elevator. The lower portion of the fixed shaft is connected with a sucker rod clamping mechanism. The sucker rod elevator is high in mechanization degree, rapid clamping of the sucker rod can be achieved, and therefore the sucker rod can be conveniently screwed on and screwed off, the operator labor intensity existing in manual centering clamping operation is lowered, the work efficiency is improved, potential safety hazards of on-site operation are reduced, and safeand civilized production is ensured; and the sucker rod elevator is connected with a mechanically-driven power tong device, and therefore the automation degree is high, and the sucker rod can be automatically screwed on and screwed off.

Owner:SENIOR AI EQUIP CO LTD

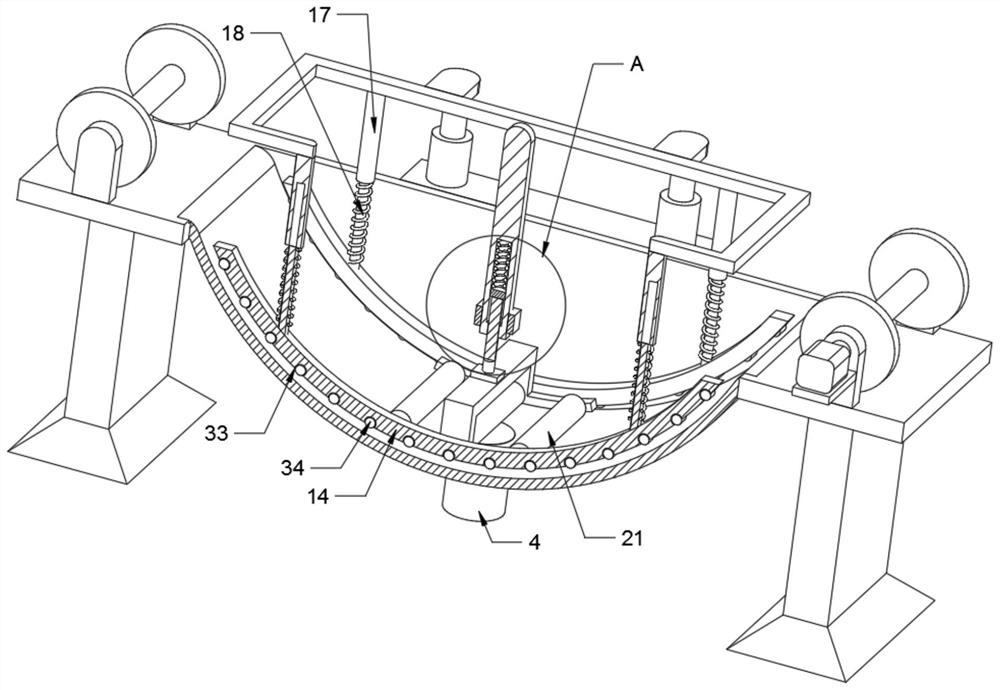

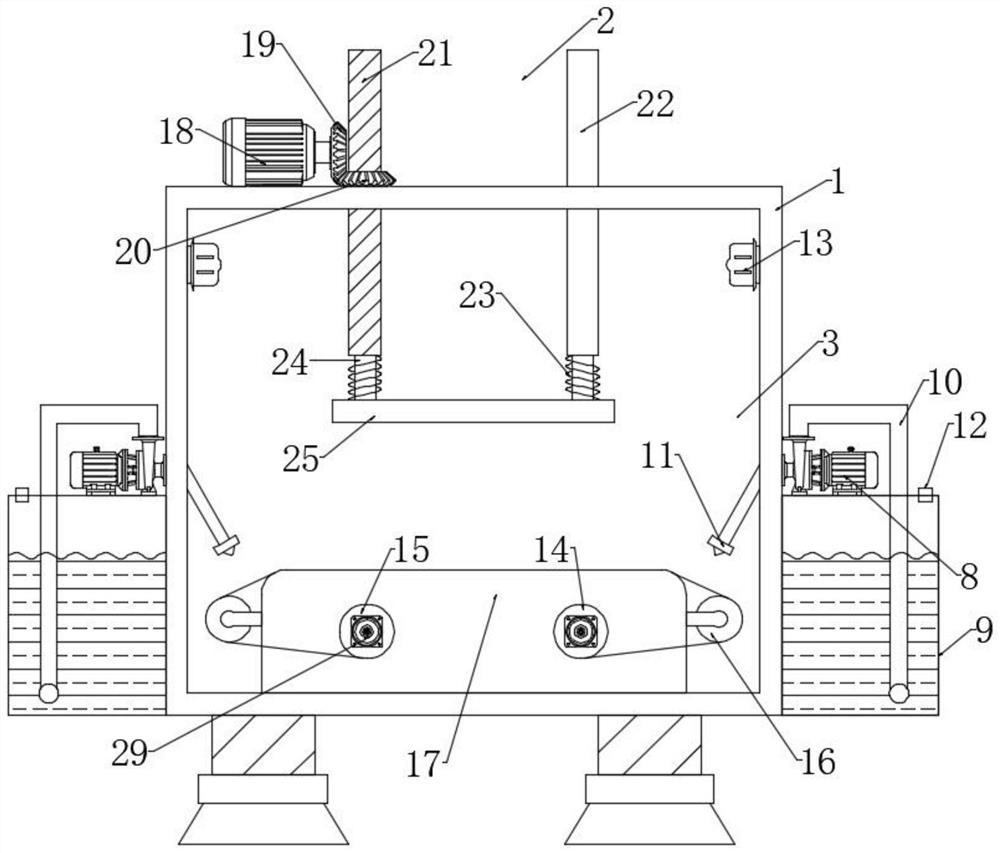

Garment cloth extruding and cleaning equipment in field of garment processing machinery

InactiveCN111979669AImprove cleaning efficiencySave human effortLiquid/gas/vapor removalTextile treatment machine arrangementsMechanical engineeringPleat

The invention relates to the technical field of garment cloth extruding and cleaning equipment, in particular to garment cloth extruding and cleaning equipment in the field of garment processing machinery. The equipment comprises a cleaning box, a cloth pressing device and an extruding and cleaning device, wherein the left side and the right side of the cleaning box are provided with flat plates correspondingly, the middle part of the cleaning box is provided with an arc-shaped box body, supporting structures are fixedly connected to the lower ends of the left side and the right side of the cleaning box, the lower portion of the cleaning box is fixedly connected with a filter screen, the surface of the cleaning box is fixedly connected with a drain pipe, the drain pipe is provided with a valve, each of the left side and the right side of the cleaning box is provided with a corresponding pair of bearing seats symmetrically, a cloth feeding roll is rotationally connected between the twobearing seats on the left side, a cloth winding roll is rotationally connected between the two bearing seats on the right side, a servo motor is fixedly installed on one of the bearing seats on the right side, and an output shaft of the servo motor is fixedly connected with the cloth winding roll. According to the equipment, brake cleaning of cloth is achieved, the labor intensity is reduced, thecleaning efficiency is improved, the cloth is prevented from wrinkling in the cleaning process, and long cloth can be cleaned in a process mode.

Owner:郑东

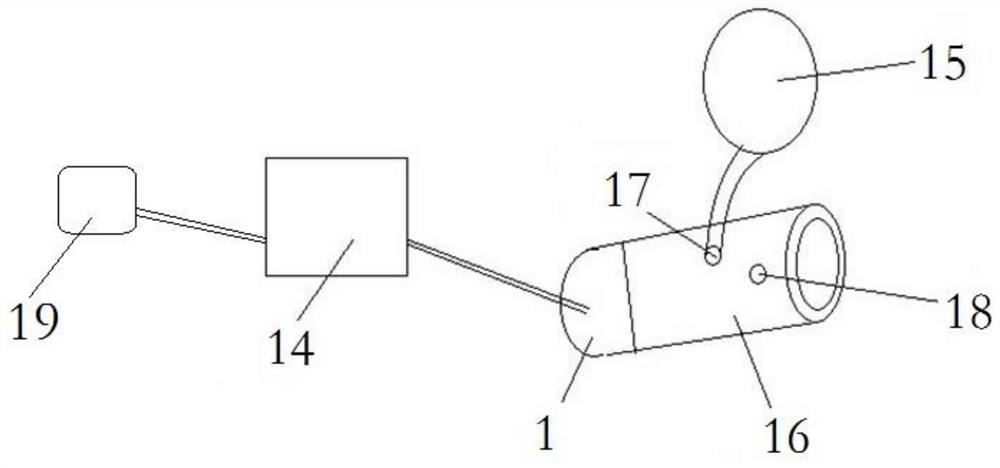

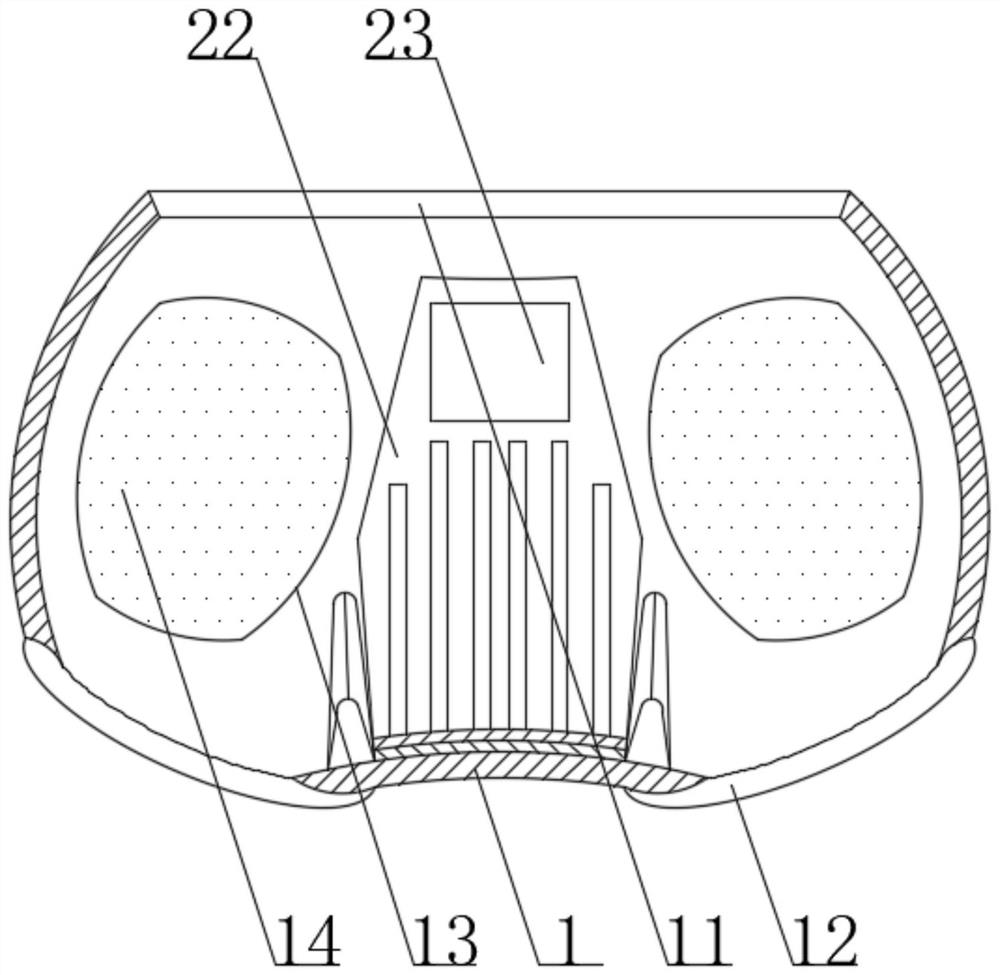

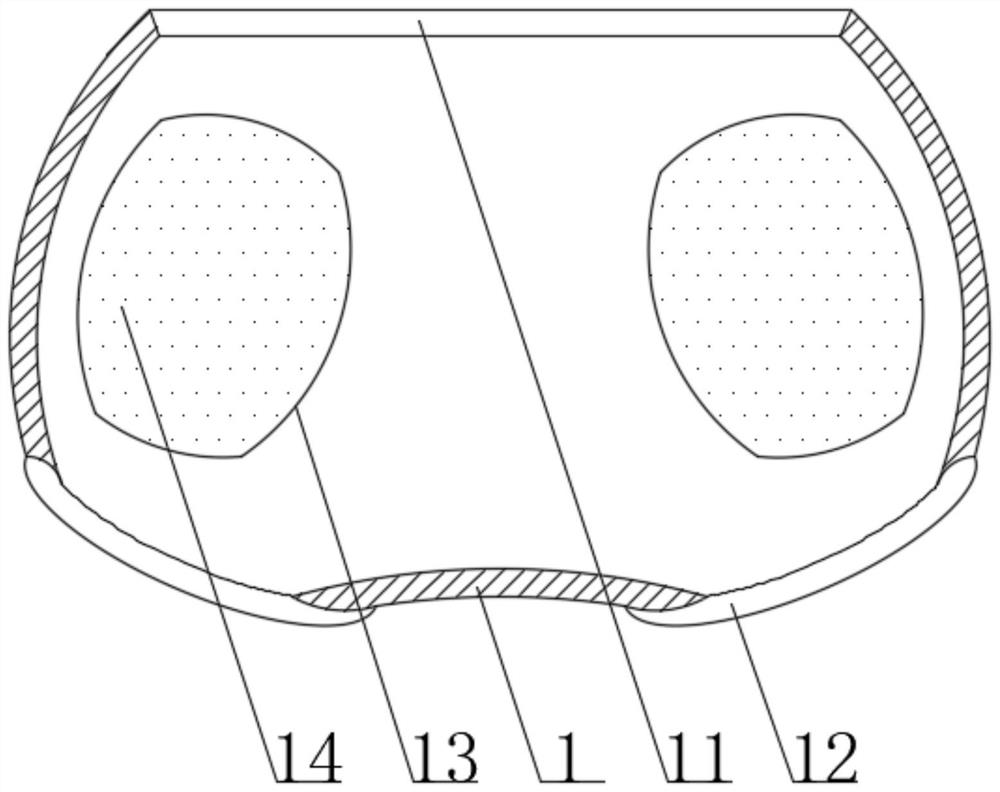

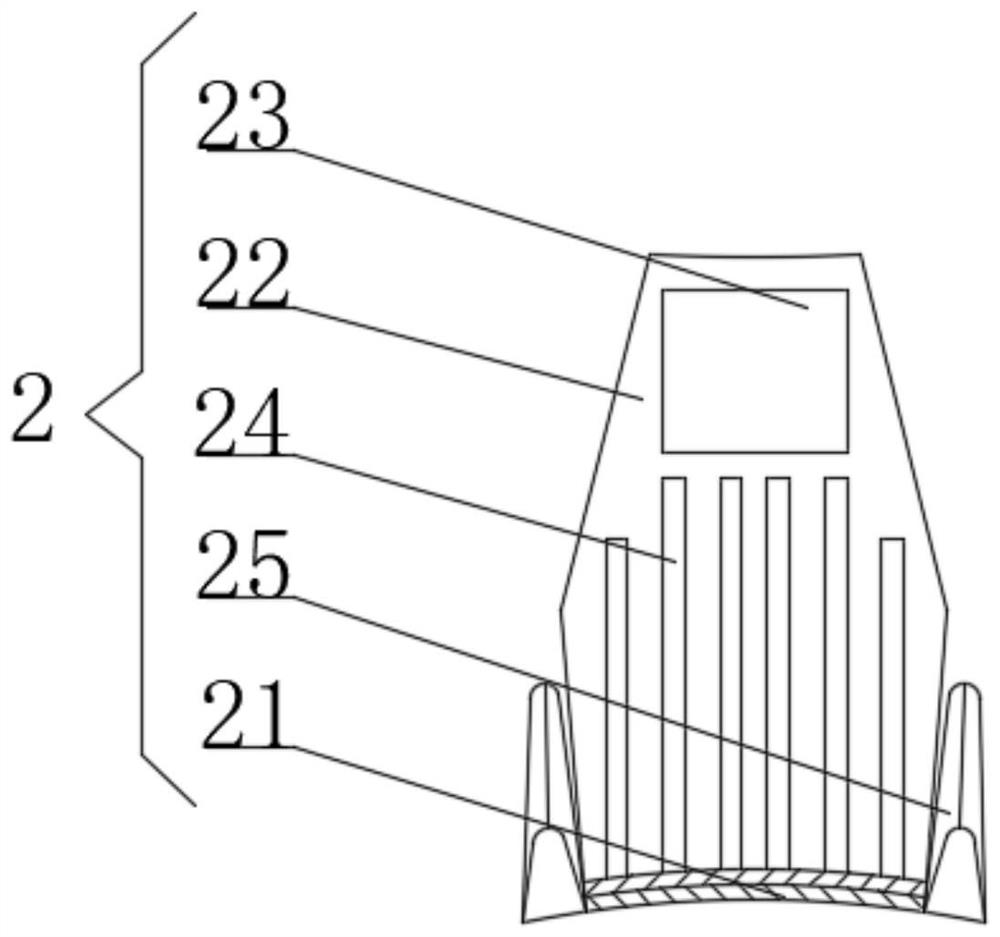

Arteriovenous blood oxygen monitor

PendingCN113796857AReduce discomfortSimple structureDiagnostic recording/measuringSensorsOxygen monitorsPatient comfort

The invention provides an arteriovenous blood oxygen monitor, and belongs to the technical field of medical equipment. The arteriovenous blood oxygen monitor comprises a host, a vein detection assembly and an artery probe fingerstall; the vein detection assembly is provided with a detection patch suitable for being attached to a vein part of the human body; the vein detection assembly is connected with the host through a second connecting line; the artery probe fingerstall is connected with the host through a first connecting line; and at least one end of the artery probe fingerstall is provided with an opening, and an annular air bag is arranged at the opening end of the artery probe fingerstall. According to the arteriovenous blood oxygen monitor, the arterial blood oxygen saturation degree and the venous blood oxygen saturation degree can be measured at the same time, the annular fingerstall can adjust the fixing strength of the arterial probe fingerstall and the finger, adjustment is conducted according to the conditions and needs of a patient, discomfort of the patient in the process of wearing the fixed arterial probe fingerstall is reduced, and the comfort of the patient in the monitoring process is enhanced.

Owner:河北金康安医疗器械科技有限公司

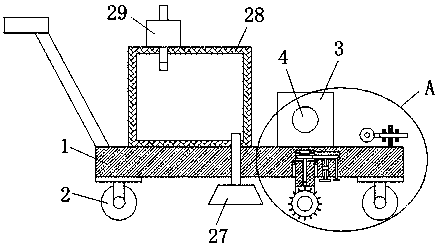

Gravity automatic adjusting polishing device

The invention discloses a gravity automatic adjusting polishing device. The gravity automatic adjusting polishing device comprises a rack. The rack is provided with a belt feeding device. The gravityautomatic adjusting polishing device is characterized in that the rack is provided with two vertical components and two transverse components, the vertical components and the transverse components form a square structure, and a plurality of fiber polishing wheels are mounted on the transverse components; sliding rails are mounted on the vertical components on the two sides of the square, polishingclamps are mounted on the sliding rails and can horizontally and transversely move on the sliding rails, and the square structure is further internally provided with a plurality of steel wire rope guiding wheels; the outer sides of the vertical components of the square structure are provided with brackets, steel wire rope guiding wheels are mounted on the brackets, and the fiber polishing wheelsare located between the polishing clamps; and steel wire ropes are mounted on the polishing clamps, mounted on the sides, close to the fiber polishing wheels, of the polishing clamps, and connected with gravity blocks sequentially through the steel wire rope guiding wheels in the square structure and the steel wire rope guiding wheels on the brackets correspondingly.

Owner:FOSHAN JULI TECH IND CO LTD

Catalytic agent capable of utilizing furfuryl alcohol liquid-phase catalytic hydrogenation to prepare 1,5- pentanedio as well asl preparation method and application of same

ActiveCN102872897BHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationMolecular sieveHydrogen atmosphere

The invention relates to a catalytic agent capable of utilizing furfuryl alcohol liquid-phase catalytic hydrogenation to prepare pentanediol, which is characterized in that an H-USY molecular sieve serves as a carrier, an isovolumetric impregnation method is adopted to introduce an active metal component, drying and roasting are carried out, and in-situ temperature-programmed reduction is carried out under a hydrogen atmosphere so as to prepare the catalytic agent. The catalytic agent has high-activity and selectivity for utilizing the furfuryl alcohol hydrogenation to prepare the pentanediol.

Owner:恒光新材料(江苏)股份有限公司

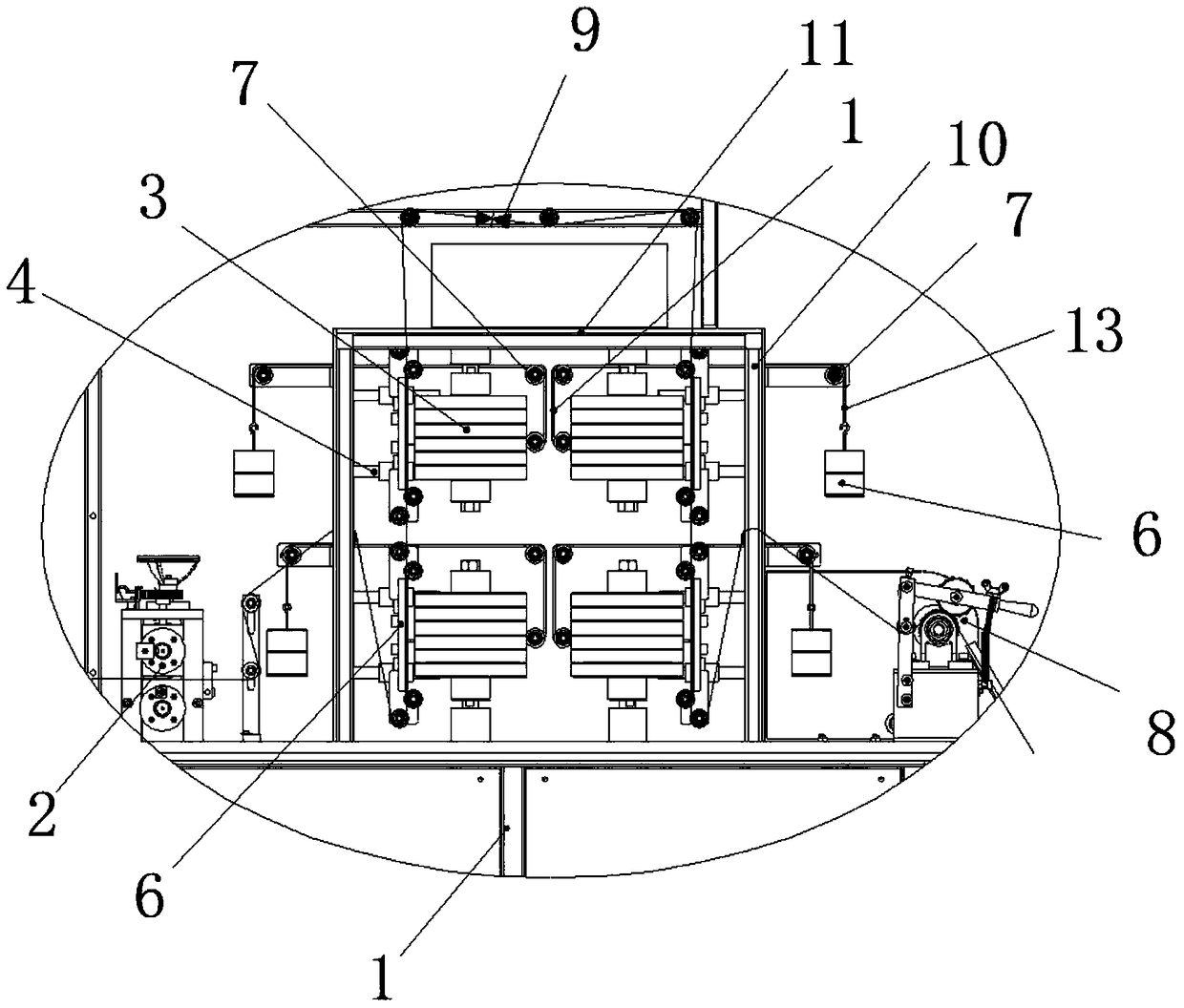

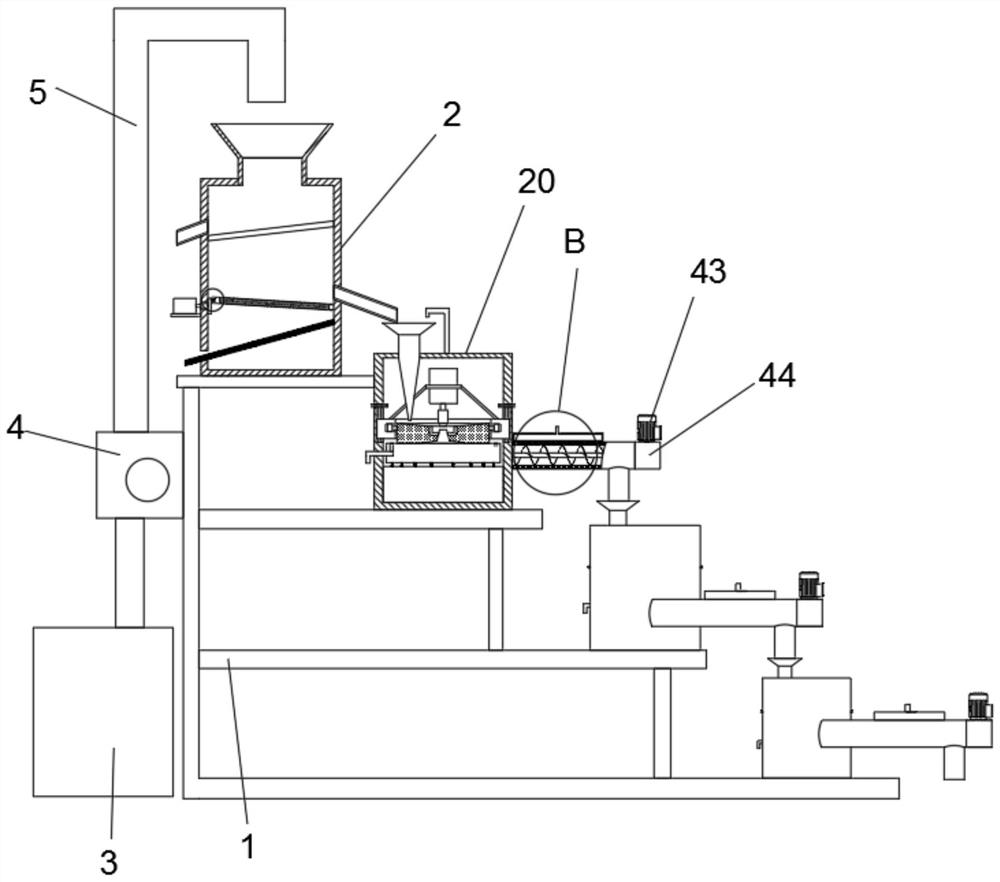

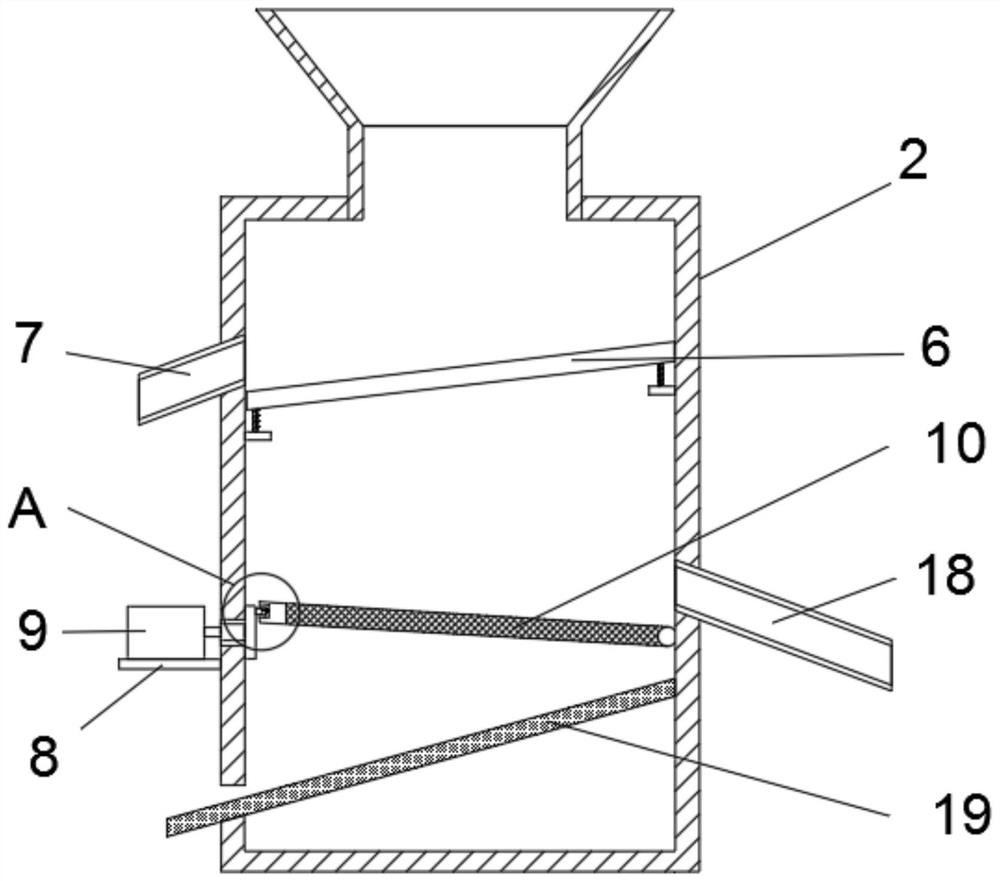

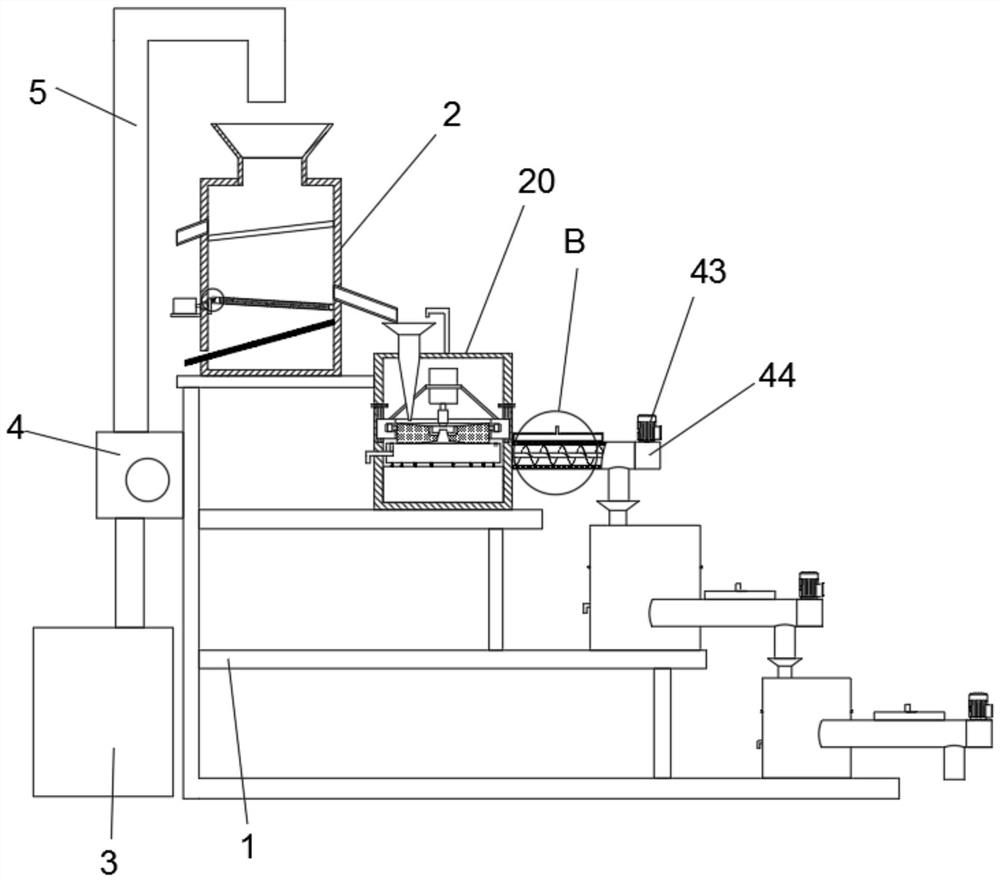

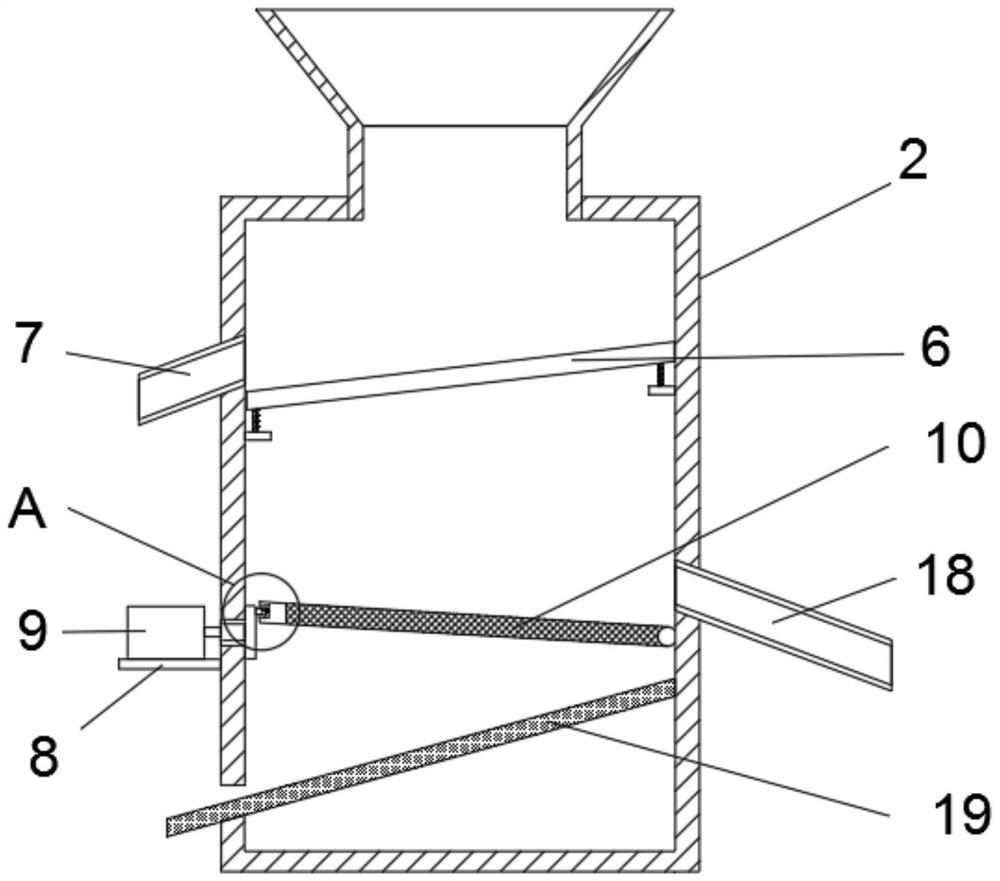

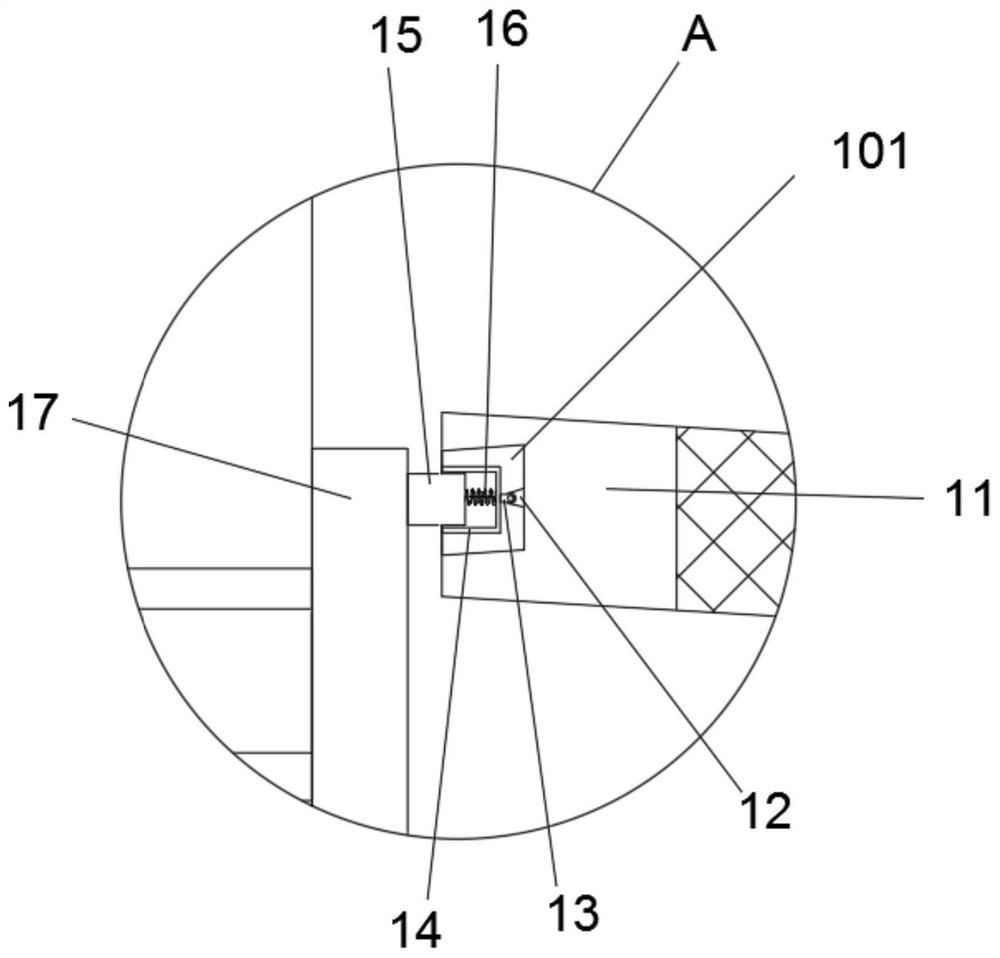

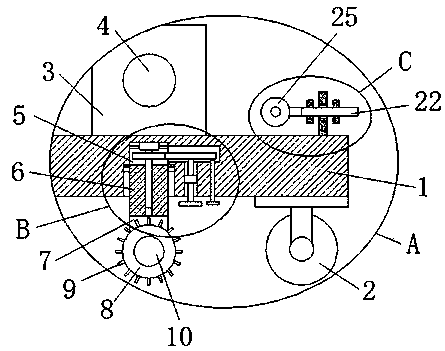

Triple mill with horizontal auger

ActiveCN112354619BSimplify the repeated pumping and refining processShorten the refining timeCocoaGrain treatmentsAugerProcess engineering

The invention discloses a triple continuous mill with a horizontal auger, comprising a bottom frame and a sieve box, the top of the bottom frame is fixedly connected with a sieve box, and one side of the sieve box is provided with a primary refining Mechanism, by setting up a multi-stage refining mechanism, using the conveying auger to transport the produced bean dregs, and adding clean water for mixing during the conveying process, the bean dregs mixed with clean water enter the next stage of refining mechanism for refining, which simplifies the grinding process. The pulper needs to carry out the process of repeated pumping and refining, which saves the refining time and improves the refining efficiency; by setting the threaded rod and the adjusting ring, turning the adjusting knob to make the threaded rod rotate, so that the meshing connection with the threaded rod The adjusting ring moves up and down, and drives the rotating grinding disc to move accordingly, and then adjusts the bonding strength between the fixed grinding disc and the rotating grinding disc, realizes the control of the particle size of the slag material, and improves the efficiency and quality of pulping.

Owner:淮南骏杰食品机械有限公司

Multi-direction adjustable sealing device used for carling air passing chamber of grate cooler

ActiveCN103884195BAchieving tightnessImprove sealingEngine sealsHandling discharged materialEngineeringMechanical engineering

The invention relates to a multi-direction adjustable sealing device used for a carling air passing chamber of a grate cooler. A retainer spring I is installed on a short screw in a sleeved mode to exert pressing force on an adjusting plate, wherein the short screw penetrates through the bottom of a peripheral frame. A long screw penetrates through the bottom of the peripheral frame and the adjusting plate, and a retainer spring II is installed on the long screw in a sleeved mode to exert pressing force on a wedge-shaped block. A rectangular sealing piece is located on the adjusting plate and is attached with the lower surface of a movable part. The inclined surface of a wedge-shaped sealing piece is attached to the inclined surface of the wedge-shaped block, and the vertical surface of the wedge-shaped sealing piece is attached to the lateral surface of the movable part. The peripheral frame is located outside the wedge-shaped block, the wedge-shaped sealing piece, the movable part, the rectangular sealing piece and the adjusting plate. The multi-direction adjustable sealing device is used for realizing multi-direction sealing of the movable part, the adjusting screws are used for adjusting the pressing force of the retainer springs so as to enable the sealing piece and the movable part to be tightly attached, and therefore the effect of sealing the movable part is realized.

Owner:NANJING KISEN INT ENG

Vehicle-mounted millimeter wave ultra-wideband tight coupling antenna array applied to V2X

ActiveCN113612019AImproving Impedance MatchingImprove performanceParticular array feeding systemsAntenna adaptation in movable bodiesUltra-widebandIn vehicle

The invention discloses a vehicle-mounted millimeter wave ultra-wideband tight coupling antenna array applied to V2X (vehicle-to-evening). The array is composed of a plurality of antenna arrays, each antenna array is composed of eight array units arranged according to a period, each array unit comprises a dielectric substrate, a feed structure printed on the front surface of the dielectric substrate, a dipole antenna unit printed on the rear surface of the dielectric substrate, a second dielectric substrate tightly attached to the rear of the dielectric substrate, and an acrylic plate tightly attached to the rear of the second dielectric substrate. The feed balun is arranged on the ground of the Marchand balun, and a hole digging microstrip line is added, so that the impedance matching capability of the balun is enhanced. The vehicle-mounted antenna array is manufactured by PCB printing, is simple in structure, and does not need later assembly, the acrylic plate is used as the back plate to enhance the stability of the structure so as to cope with a bumpy vehicle-mounted environment, and the antenna array can work in a millimeter wave frequency band, has the advantages of saving space and being low in cost, and has a good application prospect in the field of future vehicle networking.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

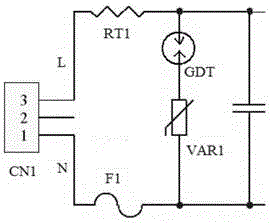

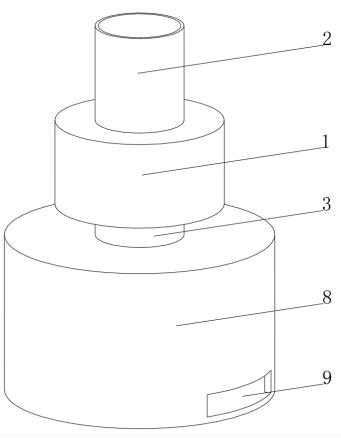

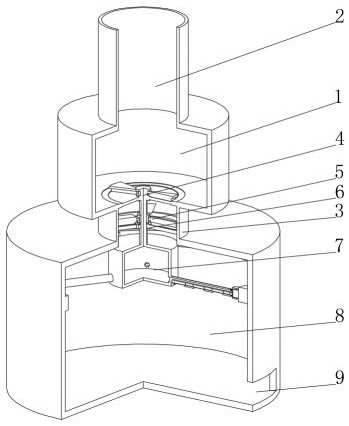

Power source

InactiveCN105281546AEasy to replaceAdjust fitPower conversion systemsEngineeringMechanical engineering

The invention discloses a power source comprising a resin tank and upper and lower rollers arranged above the resin tank. The upper roller and the lower roller are mounted on a bracket which is provided with adjustment holes. A rolling shaft is arranged at the right side of the lower roller. A beam is arranged on the bracket. One end of the beam is mounted on the bracket, and the other end of the beam is connected with the rolling shaft. The beam is provided with rolling shaft adjustment holes. According to the invention, the rolling shaft is added at the right side of the lower roller to scrape molding resin adhered to the lower roller so as to make the molding resin on the lower roller more uniform; both the upper roller and the lower roller are mounted on the bracket, and the bracket which is provided with a plurality of adjustment holes, so that the distance between the lower roller and the molding resin surface can be adjusted according to the oil content of the molding resin in the resin tank; and the beam is provided with rolling shaft adjustment holes, so that on one hand, the degree of matching between the roller and the rolling shaft can be adjusted, and on the other hand, the rolling shaft is easy to replace.

Owner:CHONGQING ZEQINGJU SCI & TECH DEV

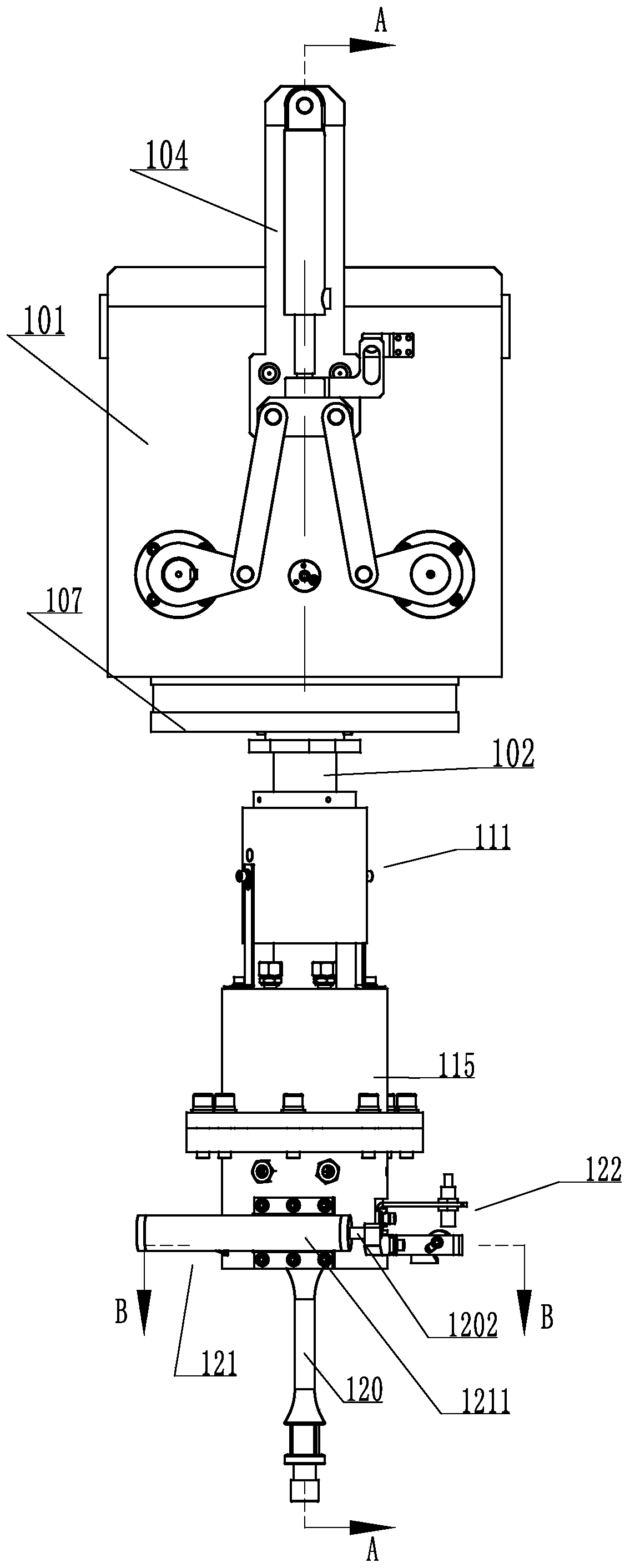

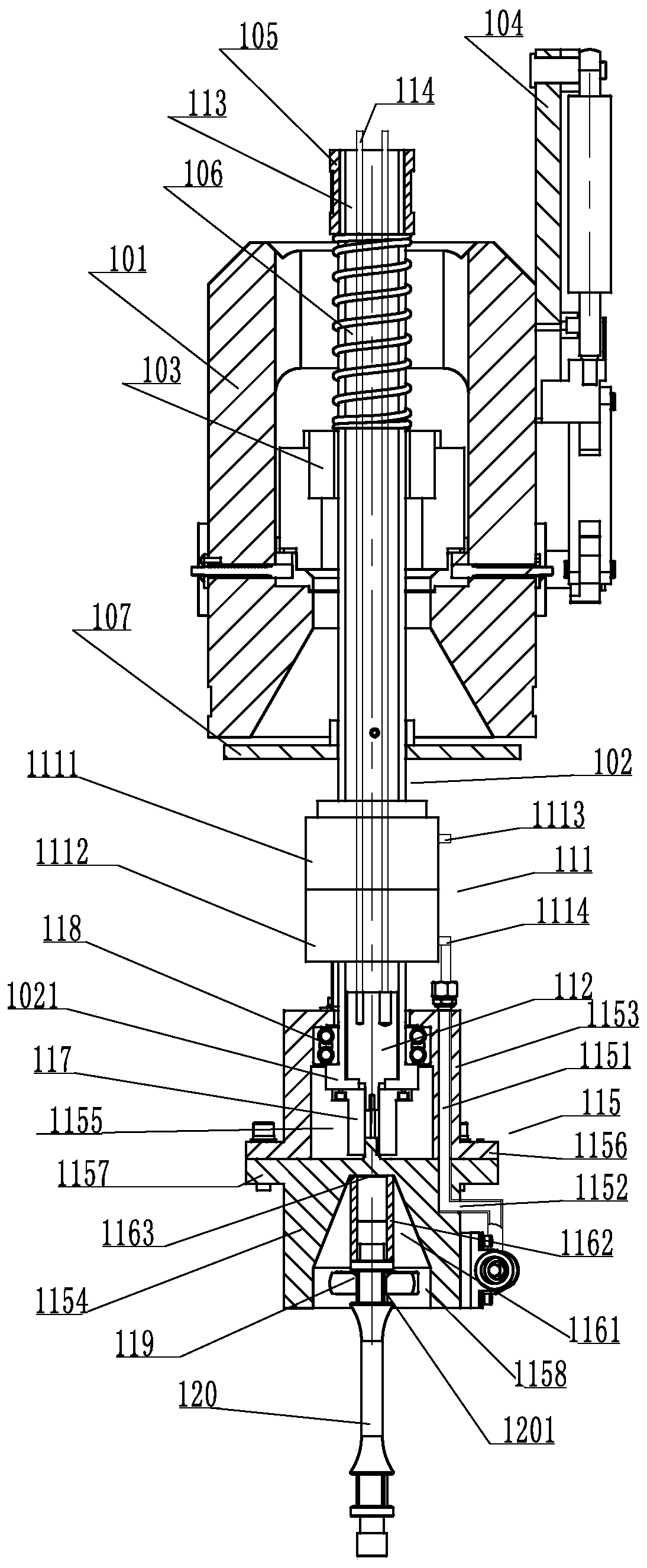

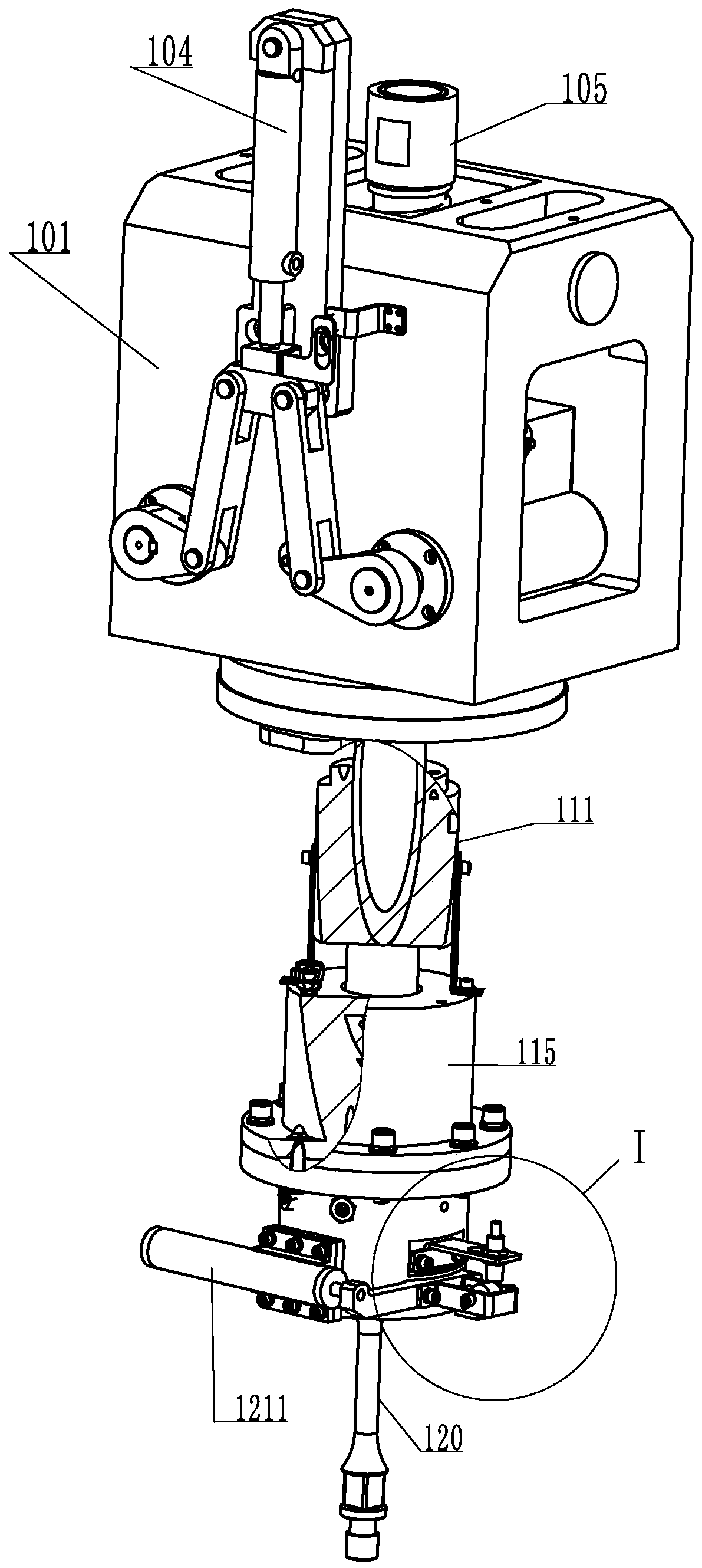

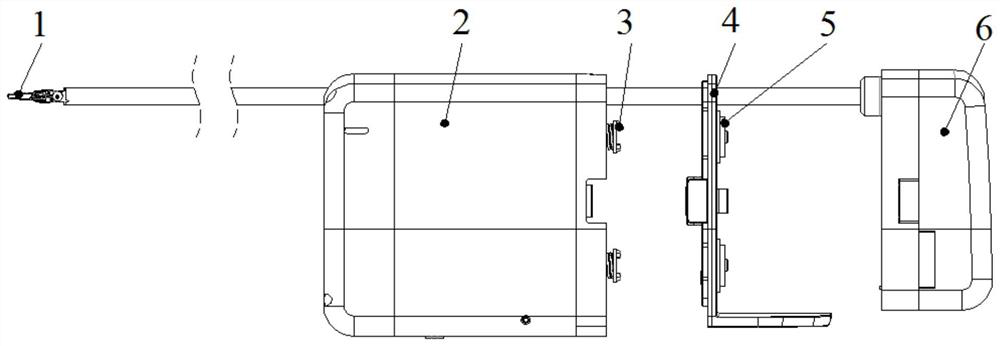

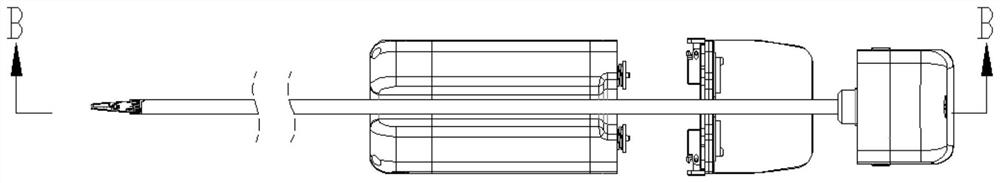

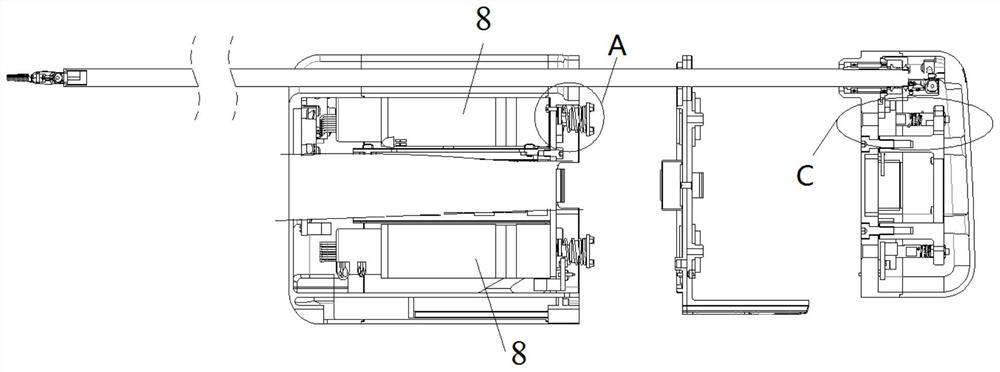

Surgical robot

ActiveCN112402019AHigh concentricityAdjust fitMechanical energy handlingSurgical robotsPhysical medicine and rehabilitationEngineering

The invention discloses a surgical robot, which comprises a driving device, an output flange and an adapter flange arranged on a sterile separation base assembly, and a cutting slot extending in the circumferential direction is formed in the outer circumferential surface of the output flange; a first end of the output flange in the axial direction is inserted and matched with the adapter flange todrive the adapter flange to rotate synchronously, and a second end of the output flange is connected to an output shaft of driving device, the output shaft and the output flange rotate synchronouslyand can slide relatively in the axial direction, and an elastic piece is arranged between the output flange and the output shaft to axially press the output flange on the adapter flange. Due to the fact that the cutting slot is formed in the output flange, it is guaranteed that the output flange and the adapter flange can be inserted together through stress deformation of the cutting slot, and therequirement for the machining precision of the adapter flange and the output flange can be lowered.

Owner:CHONGQING JINSHAN MEDICAL ROBOTICS CO LTD

Underpants for menstrual period

The underpants comprise an underpants body and an adsorption layer mechanism, adjusting bag mechanisms are arranged on the two sides of the middle of one side of the inner wall of the underpants body, the adsorption layer mechanism is arranged in the middle of the lower surface of the inner wall of the underpants body, and the adsorption layer mechanism further comprises an absorption core layer; a protection pad layer is arranged on one side of the absorption core layer, and skin separation pads are arranged on the two sides of the periphery of the absorption core layer; the fitting effect of the underpants body and the buttocks of a user can be effectively adjusted through the adjusting bag mechanism, the interval space between the skin and the underpants body can be flexibly adjusted, then the ventilation and dredging effects are achieved, meanwhile, an adsorption core filtering layer is arranged in the adjusting bag mechanism, gas can be effectively absorbed, and the air permeability is improved. By arranging the net-shaped activated carbon layer, the effect of eliminating peculiar smell can be effectively achieved, so that the wearing experience of a user in daily activities is greatly improved, and the wearing comfort of the underpants body is improved.

Owner:广东冰冰护理用品有限公司

Wall-hanging stove face shell structure

PendingCN109883054AHigh strengthEasy to installFluid heatersSpace heating and ventilation detailsEngineeringUltimate tensile strength

The invention discloses a wall-hanging stove face shell structure. The structure comprises a face shell body with an arc face, and is characterized in that a supporting pad is arranged in the face shell body, a supporting arc face is arranged on the supporting pad, the supporting arc face is tightly attached to the inner side of the arc face, the supporting pad is added in the face shell body, theeffect of reinforcing the strength of the whole face shell body is achieved, the phenomenon that after a face shell is mounted, the arc face springs back is effectively avoided, during total assembly, assembling error is avoided, and the face shell assembling qualification is ensured.

Owner:MACRO THERMAL ENERGY TECH

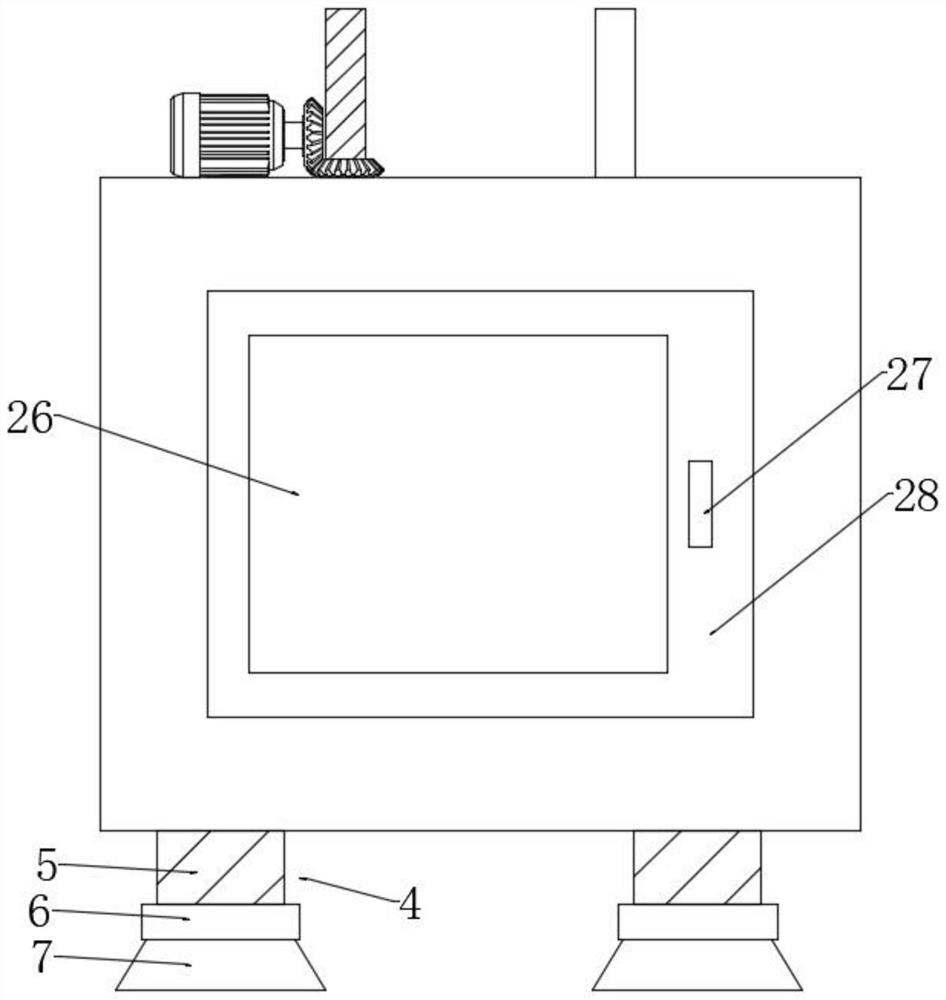

Cloth ironing device for home textiles

PendingCN114541073AAchieve pre-levellingAdjust fitTextile treatment by spraying/projectingTextile shapingElectric machineryStructural engineering

The invention discloses a home textile cloth ironing device which comprises a treatment box, a lifting assembly, humidifying assemblies and a stabilizing assembly, the lifting assembly is arranged on the upper side of the treatment box, the humidifying assemblies are suitable for the two sides of the treatment box, and the stabilizing assembly is arranged on the lower side of the treatment box. The lifting assembly comprises a sliding rod, a threaded rod, a driving motor, a driving bevel gear, a driven bevel gear, a telescopic column, a spring and an ironing plate, the driving motor is fixedly arranged on the outer wall of the top of the treatment box, the driving bevel gear is rotationally arranged on the outer wall of the top of the treatment box, and the driven bevel gear is rotationally arranged on the outer wall of the top of the treatment box; the driving bevel gear is vertically meshed with the driven bevel gear, and the output end of the driving motor is fixedly connected with the center point of the driving bevel gear. The invention belongs to the technical field of cloth production, and particularly relates to a cloth ironing device for home textiles. The cloth ironing device is simple in structure, convenient to use and capable of automatically supplementing water, adjusting the pressure of an ironing plate and conducting repeated ironing.

Owner:海宁零根壹网络科技有限公司

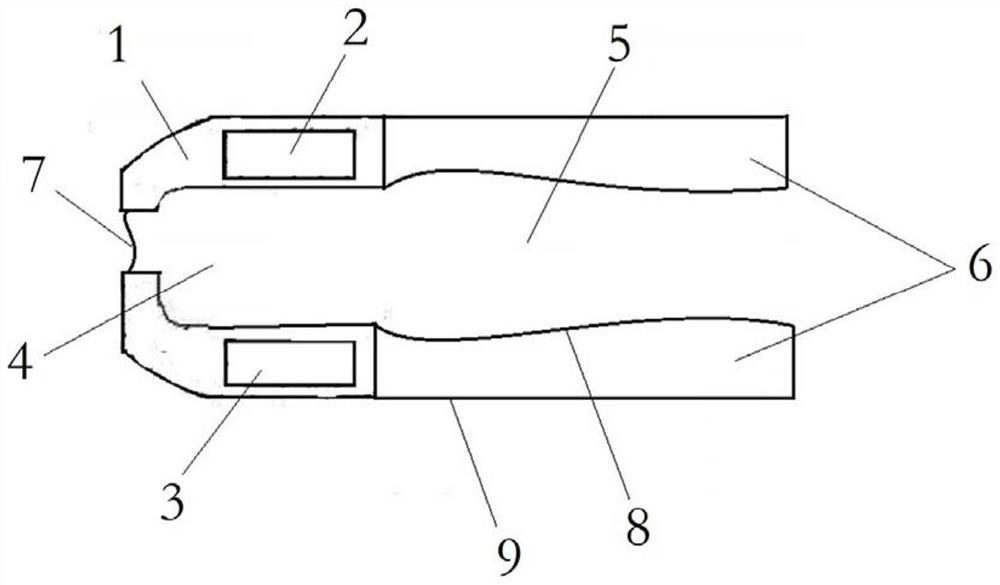

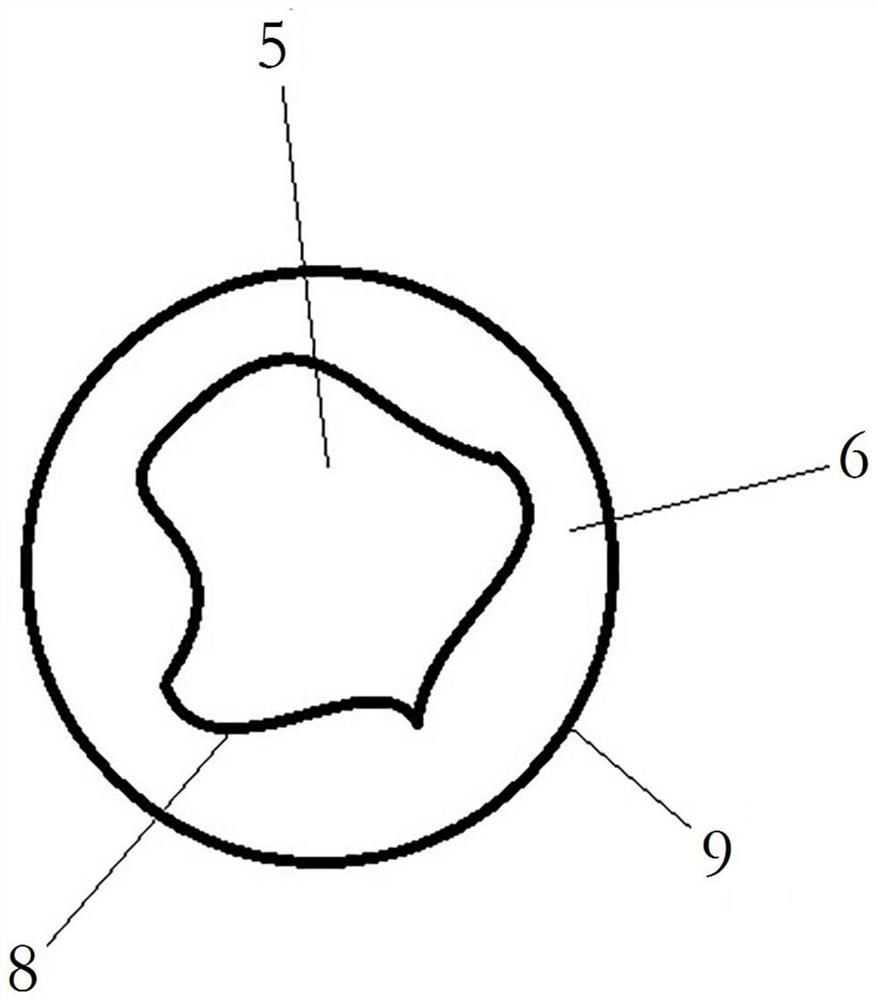

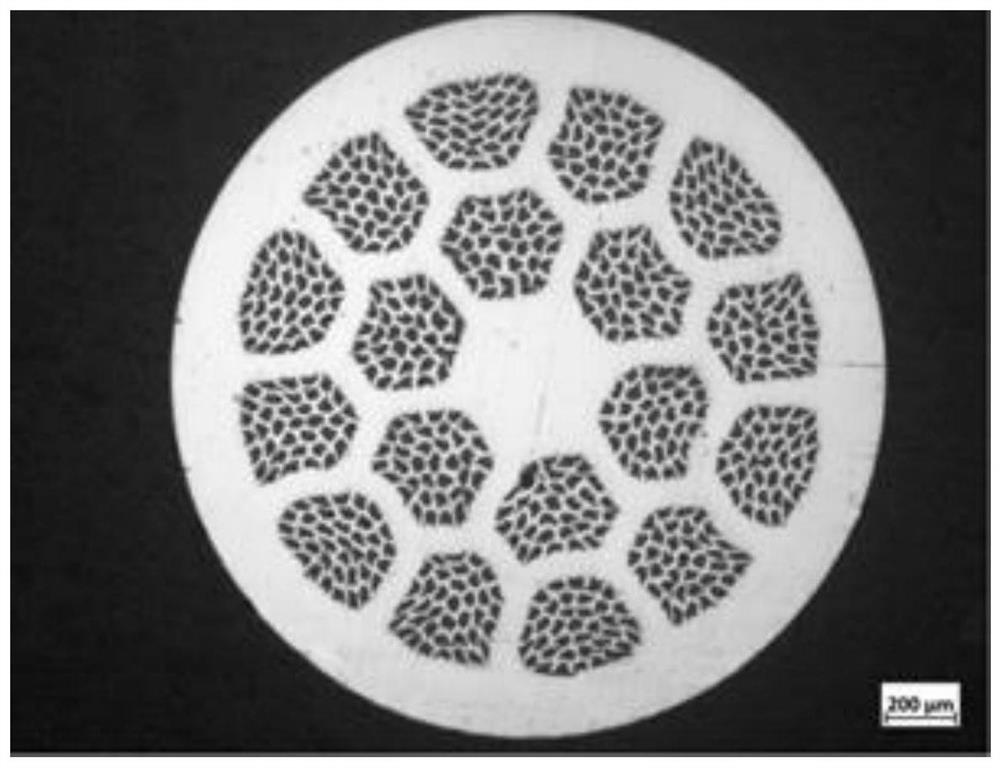

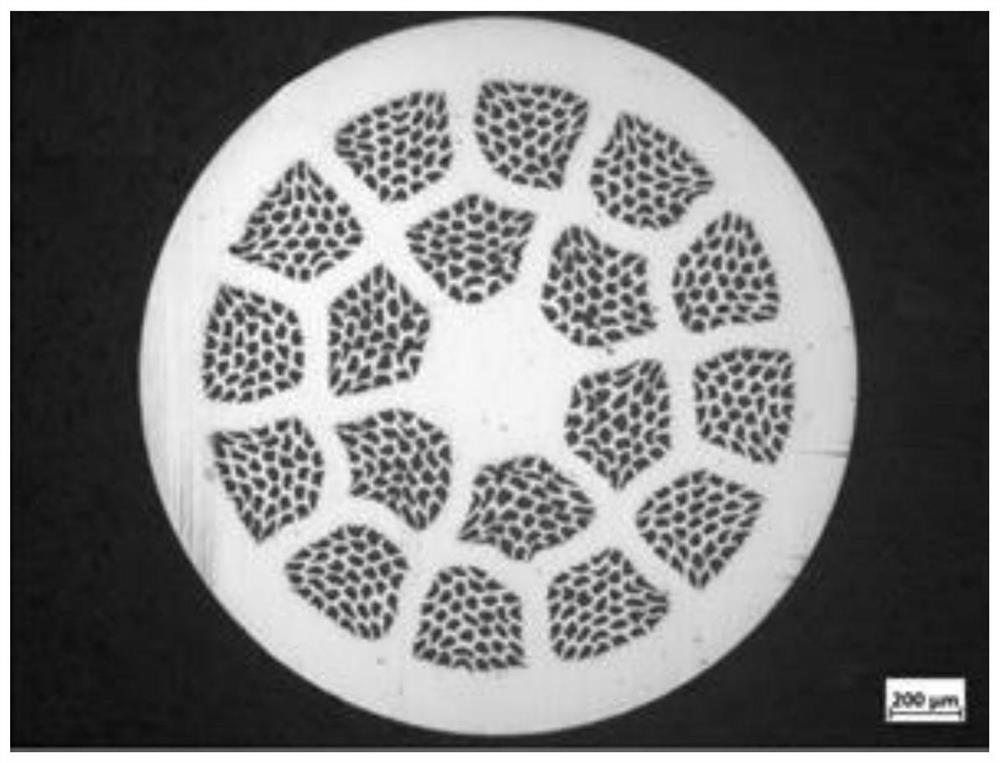

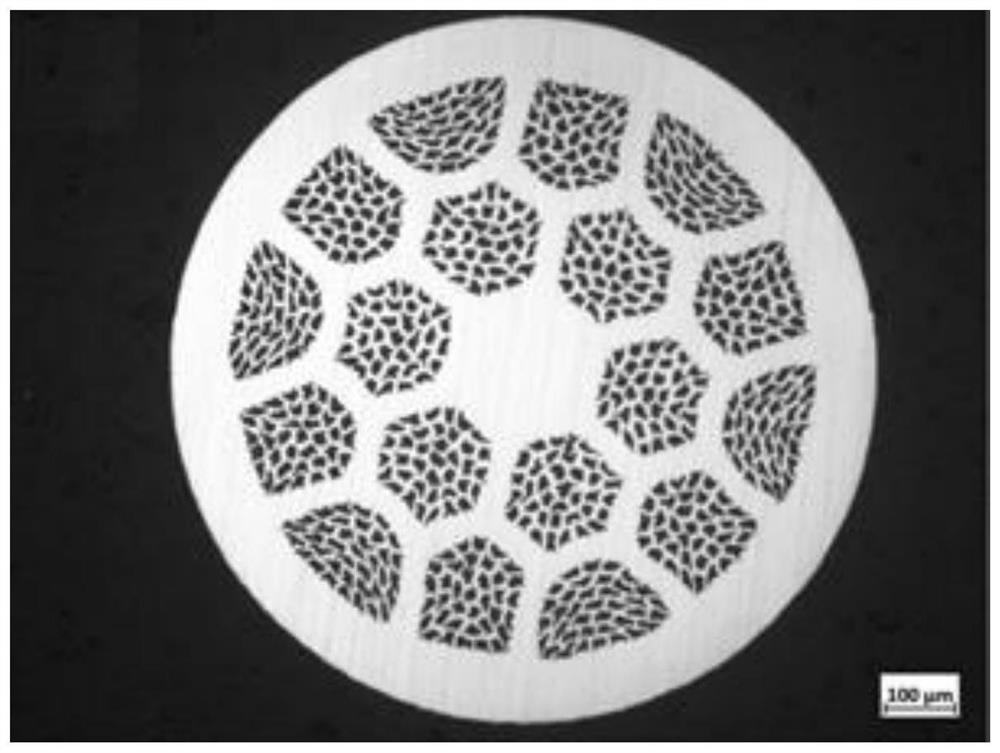

Method for optimizing processing uniformity of Bi2212 wire rod through gradient assembly

PendingCN114695639AAdjust fitImproved co-deformabilitySuperconductor device manufacture/treatmentWire rodStructural engineering

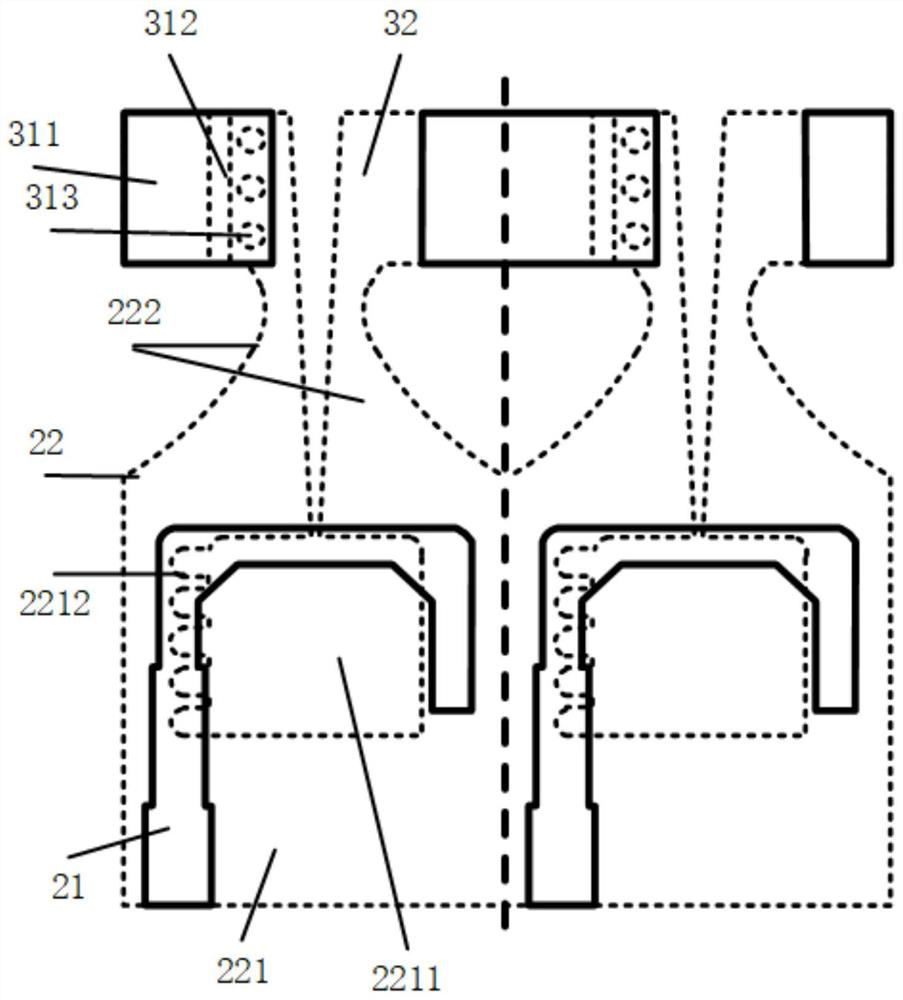

The invention discloses a method for optimizing processing uniformity of a Bi2212 wire rod by gradient assembly, which is characterized in that in a secondary assembly process of a conventional processing technology of the Bi2212 wire rod, a gradient assembly method is adopted, and Bi2212 secondary wires are arranged circle by circle from an inner circle to an outer circle according to a silver super-ratio gradient reduction rule. By designing a gradient assembly process of Bi2212 secondary lines with different silver super ratios, a special gradient structure with a high silver super ratio Bi2212 secondary line on the inner ring and a low silver super ratio Bi2212 secondary line on the outer ring is formed, the plastic deformation of the Bi2212 secondary lines from the inner ring to the outer ring and the matching property of the plastic deformation of the Bi2212 secondary lines from the inner ring to the outer ring and the axial stress of the Bi2212 secondary lines from the inner ring to the outer ring are adjusted, the cooperative deformation of the Bi2212 secondary lines from the inner ring to the outer ring is improved, and the mechanical property of the Bi2212 secondary lines from the inner ring to the outer ring is improved. The processing uniformity of the Bi2212 wire rod is optimized from the intrinsic aspect, and the method has good application advantages and engineering prospects in the processing process of the Bi2212 wire rod.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A method and device for adjusting a user seat

The purpose of this application is to provide a method for adjusting a user's seat, which specifically includes: receiving user posture information sent by the user device when the user uses the seat; determining a method for adjusting the seat according to the user posture information; Adjustment instruction information of the chair; return the adjustment instruction information to the user equipment. This application obtains the user posture information when the user uses the seat through the user equipment, and the server determines the corresponding adjustment instruction information according to the received user posture information sent by the user equipment, wherein the adjustment instruction information is used to adjust the seat that the user is using. This application can obtain user posture information in real time, and adjust the seat accordingly according to the change of user posture, so that when the user uses the seat, the seat can always provide the best support and protection, and based on the automatic collection process of the sensor, the adjustment The process optimizes the user's tedious adjustment operations and greatly improves the user experience.

Owner:SHANGHAI CHENGTAN NETWORK TECH CO LTD

Triplet mill with screw conveyor

ActiveCN112354619ASimplify the repeated pumping and refining processShorten the refining timeCocoaGrain treatmentsScrew conveyorProcess engineering

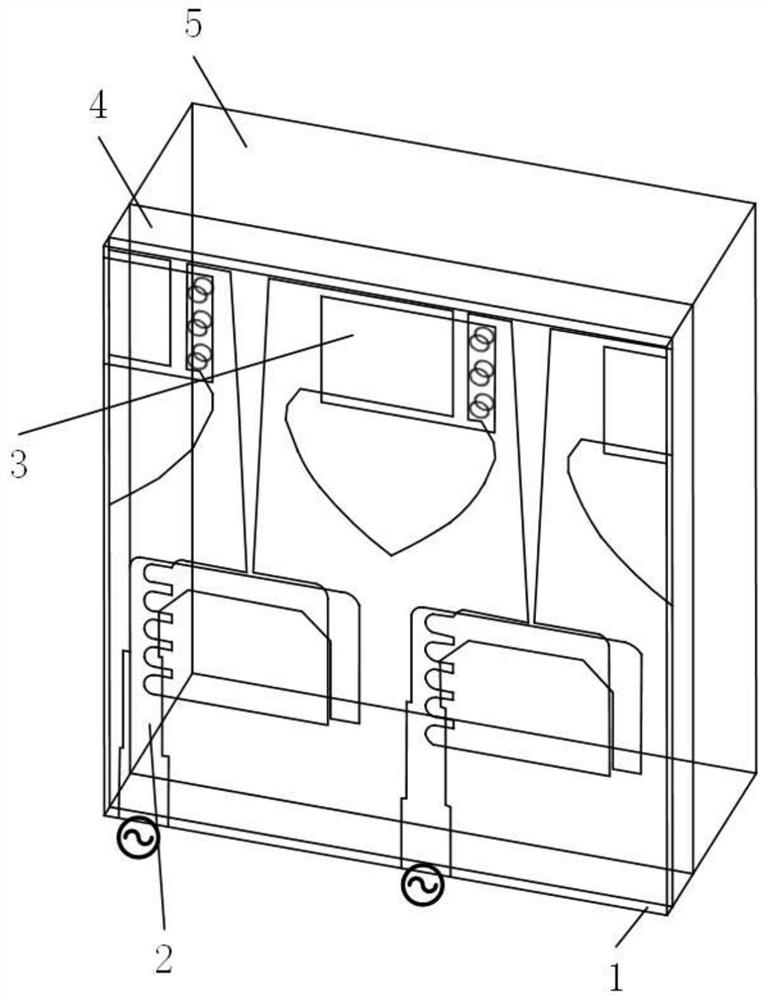

The invention discloses a triplet mill with a screw conveyor. The triplet mill comprises a bottom frame and a material screening box body, wherein the top of the bottom frame is fixedly connected withthe material screening box body, and one side of the material screening box body is provided with a first-stage grinding mechanism. By arranging the multi-stage grinding mechanisms, generated bean dregs are conveyed through the screw conveyor, clear water is added in the conveying process for mixing, the bean dregs mixed with the clear water enter the next stage of grinding mechanism to be pulped, so that the process that a grinding machine needs to repeatedly pump and grind is simplified, the grinding time is saved, and the grinding efficiency is improved; and by arranging a threaded rod andan adjusting ring and shifting an adjusting knob, the threaded rod rotates, so that the adjusting ring connected with the threaded rod in a meshed mode moves up and down and drives a rotary grindingdisc to move along with the threaded rod, then the attaching strength between a fixed grinding disc and the rotary grinding disc is adjusted, control over the slag granularity is achieved, and the slurry discharging efficiency and quality are improved.

Owner:淮南骏杰食品机械有限公司

Energy-saving sewage treatment equipment

InactiveCN114772798AAvoid cloggingImprove work efficiencyTransportation and packagingTreatment involving filtrationSewage treatmentMechanical engineering

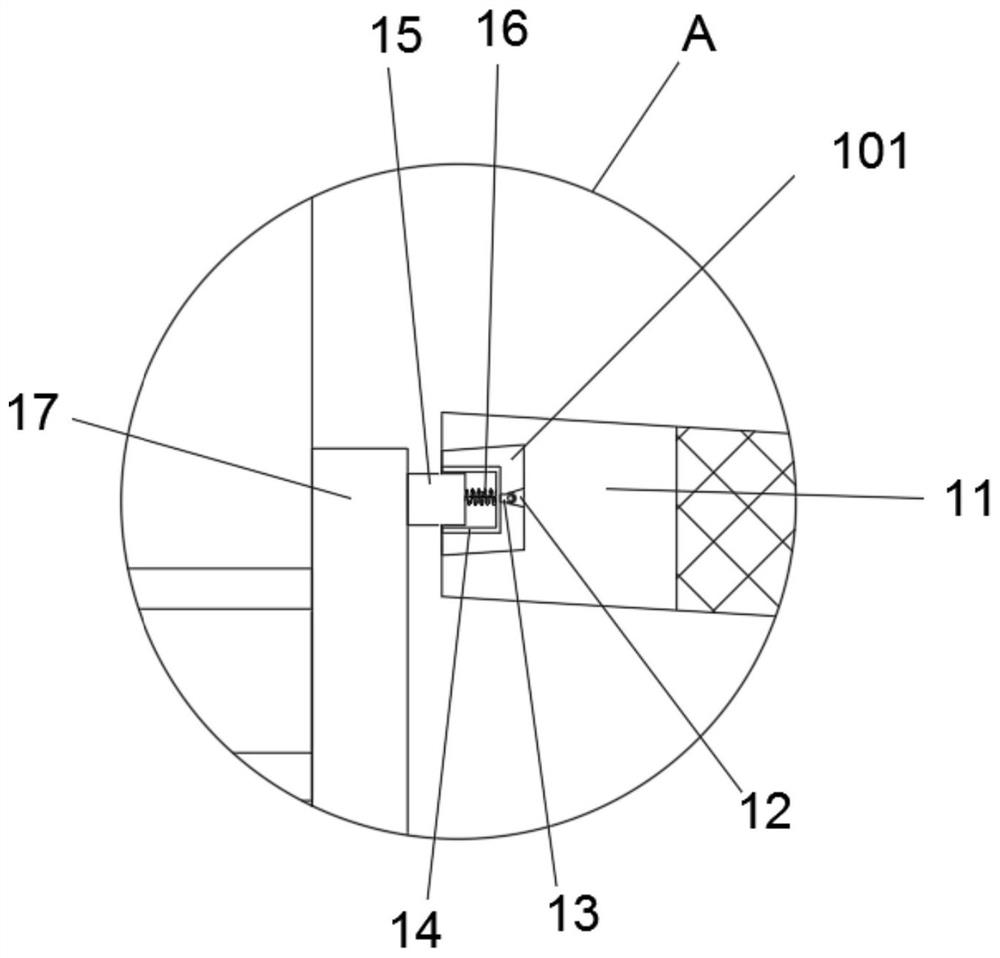

The invention discloses energy-saving sewage treatment equipment which specifically comprises a treatment disc, the center positions of the top and the bottom of the treatment disc are respectively communicated with a water inlet pipe and a treatment pipe, and the top of the inner wall of the treatment pipe is provided with a filtering device; the spiral fan is arranged in the treatment pipe, a fixed shell is arranged on the outer side of the spiral fan, the outer side of the fixed shell is fixedly connected with the inner wall of the treatment pipe, the top of the spiral fan is connected with a filtering device through a rotating shaft, and the bottom of the spiral fan is fixedly connected with a discharging device through a rotating shaft; the top of the treatment box is communicated with the bottom of the treatment pipe, and a water outlet is formed in one side of the treatment box. According to the energy-saving sewage treatment equipment, the surface of the filter screen can be automatically cleaned through the brush head, the filter screen is prevented from being blocked by impurities accumulated on the surface of the filter screen, the filter screen does not need to be frequently detached and cleaned, the working efficiency is high, and the labor cost is saved.

Owner:NANTONG SAFE MACHINERY EQUIP

A portable road sweeper

The invention discloses a portable road sweeper, including a fixed base, wherein universal wheels are arranged at four corners of the bottom of the fixed base, and the top of the fixed base is fixedlyconnected with a driving motor, and a first belt pulley is fixedly installed on the output shaft of the driving motor, and a mounting groove arranged at the bottom of the fixed base is directly belowthe first pulley, and a support rod is slidably mount in the mounting groove, and the bottom end of the support rod extend to the lower part of the fixed base and is welded with a mounting plate. Oneside of the mounting plate is rotatably mount with a shaft roller, and a plurality of bristles are fixedly adhered on the outer side of the shaft roller, and a second belt pulley is fixedly mounted on an end of the shaft roller away from the mounting plate. The invention has the advantages of reasonable design, high practicability, convenient operation and control, and is convenient to adjust theheight of the shaft roller, thereby being able to adjust the fitting strength between the bristles and the road surface, so that the shaft roller can better sweep up the road surface dust when the shaft roller is in use, and the road cleaning efficiency is improved.

Owner:泰州市津专知识产权服务有限公司

Rubber belt type vacuum filter discharge device

InactiveCN101485943BApplicable dischargeAdaptableMoving filtering element filtersFiltrationInlet pressure

The invention relates to a scraper discharging device, in particular to the scraper discharging device of filtration fabric of a rubber belt type vacuum filter. The scraper discharging device comprises a scraper support saddle and a scraper bracket arranged on the scraper support saddle, wherein the scraper bracket is pivoted with a scraper by a bearing; the scraper comprises a scraper body and asqueeze plate for squeezing the scraper body; the scraper body and the squeeze plate are positioned at the two sides of the bearing respectively; one ends of a plurality of bent levers are fixedly connected with the squeeze plate of the scraper; and the other ends of the bend levers are linked with an air bag. The output force of the air bag can be controlled by adjusting inlet pressure through apressure regulating valve so as to conveniently adjust condition of the action of the scraper and a discharging roll and avoid damage to the filtration fabric.

Owner:湖州旺能环保科技有限公司

Automatic grinding device and grinding method

ActiveCN106625102BImprove grinding efficiencyLow costEdge grinding machinesGrinding work supportsEngineeringFriction force

The invention discloses an automatic grinding device and a grinding method. The device comprises a first jig and a second jig which are arranged oppositely and can rotate relatively; workpieces to be ground are fixed on the first jig and the second jig respectively, and molten slag surfaces of the workpieces to be ground are arranged oppositely. The device adopts the two jigs capable of rotating relatively and workpieces including ceramic and the like are arranged between the two jigs; the two jigs are controlled to rotate relatively so that the two workpieces are driven to rotate relatively; molten slag is removed by utilizing friction force between the two workpieces; the rigidity of materials of the workpieces is consistent, so that damages to the materials are not caused in a rubbing process; and the problems that the loss of a shovel plate and the materials are prone to being damaged in a traditional grinding process are solved by the device. By adopting the device and the method, two workpieces can be machined simultaneously, so that the grinding efficiency is high and the cost is low.

Owner:CHANGZHOU INNO MACHINING

Peculiar smell removal composite fiber containing probiotics and preparation method of peculiar smell removal composite fiber

InactiveCN112695476AGuaranteed comfortAvoid physical problemsLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine partsFiberPolymer science

The invention relates to the technical field of peculiar smell removal composite fibers, and discloses a peculiar smell removal composite fiber containing probiotics and a preparation method of the peculiar smell removal composite fiber. A buffer piece is movably connected to the upper part of a metal frame. The preparation method comprises the steps that a material opening is opened, unprocessed acid-beneficial bacteria are poured into the material opening, the acid-beneficial bacteria run along a groove of the material opening and enter an action disc, a threaded rod is movably connected into the action disc, the threaded rod and the action disc run synchronously, the effect of suction force is achieved on a spring pressing block, so that the acid-beneficial bacteria in a core rotating disc are sucked into an allergy-free polyvinyl alcohol box below the rotating disc to be made into the composite fiber, the allergy-free function is achieved, even if some people belong to allergic constitution and make contact with the composite fiber, the allergy condition cannot occur, the body discomfort of the people with the allergic constitution is prevented, so that the comfort level of allergic people is guaranteed, and the effects of preventing allergy and improving the experience feeling are achieved.

Owner:浙江寻叶新材料科技有限公司

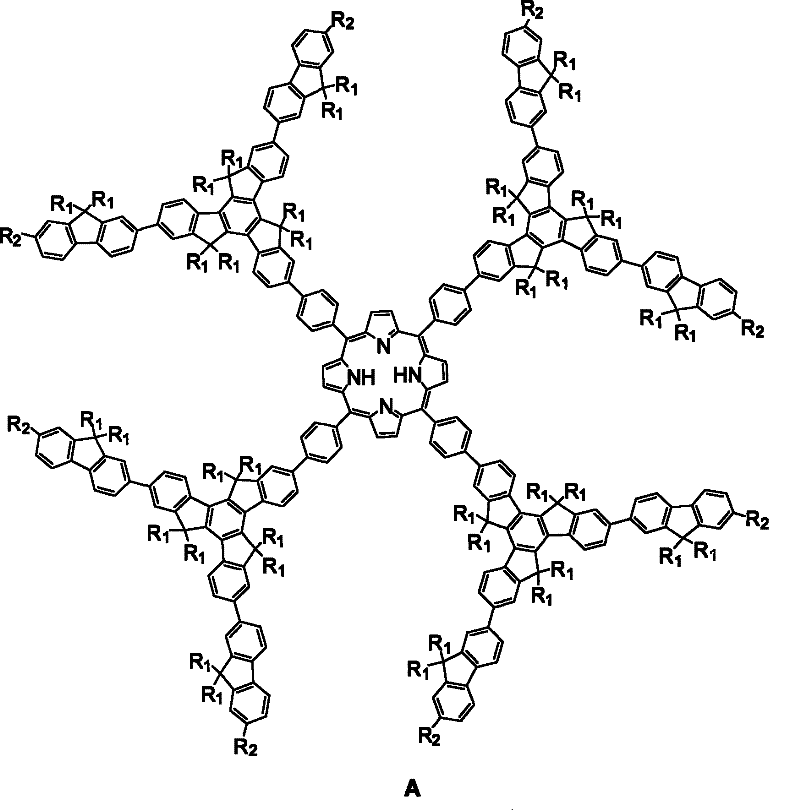

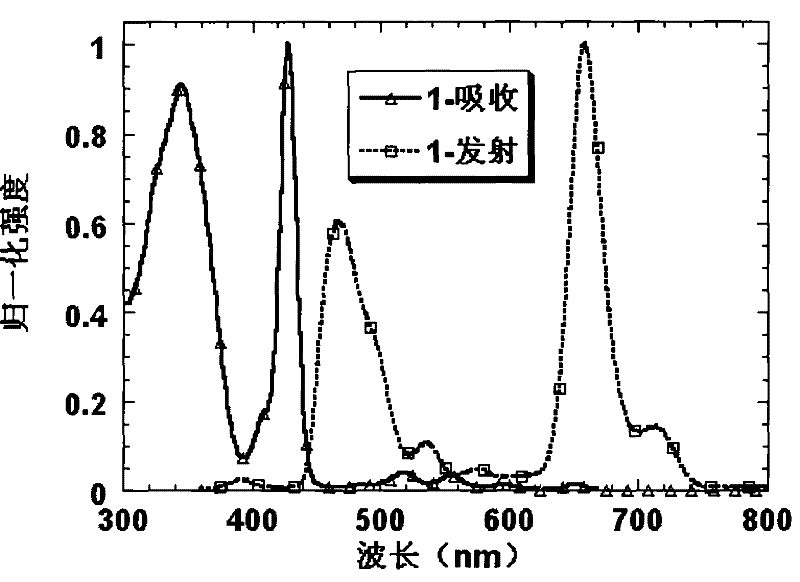

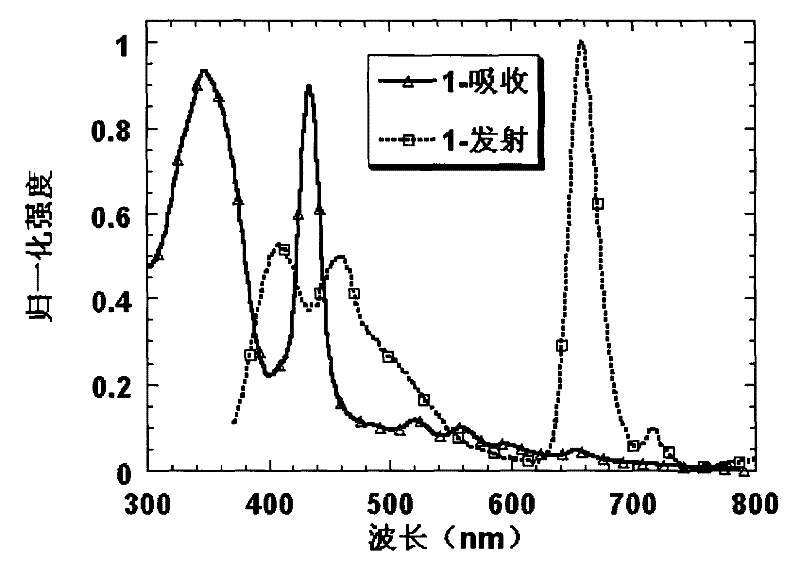

Conjugated dendritic electrically-induced pure red material and preparation method and use thereof

InactiveCN101418002BImprove solubilityEffective isolationOrganic chemistrySolid-state devicesSolubilityPorphyrin molecule

The invention provides conjugated dendritic pure red light emitting electroluminescent material, and a preparation method and application thereof. The material has a conjugated dendritic molecule which takes porphyrin as a core, truxene as a bridge and monofluoride as an antenna molecular and has a structural formula A. The material is prepared by the Lindsey condensation reaction of a derivativehaving a methanoyl of the truxene and the porphyrin. The method introduces a truxene system having a hydrotropic group to a metaposition of a porphyrin molecule to improve the solubility of the material and suppress fluorescence self-quenching, and increases intramolecular and intermolecular energy transfer through derivatization at 2, 7, 12-position of the truxene, so as to obtain high-efficiency pure light emission. The conjugated dendritic molecules are used as materials for a light emitting layer of an organic electroluminescent diode device and made into films by a simple spin coating process, and generate high-efficiency pure red light electrofluorescence without doping.

Owner:PEKING UNIV

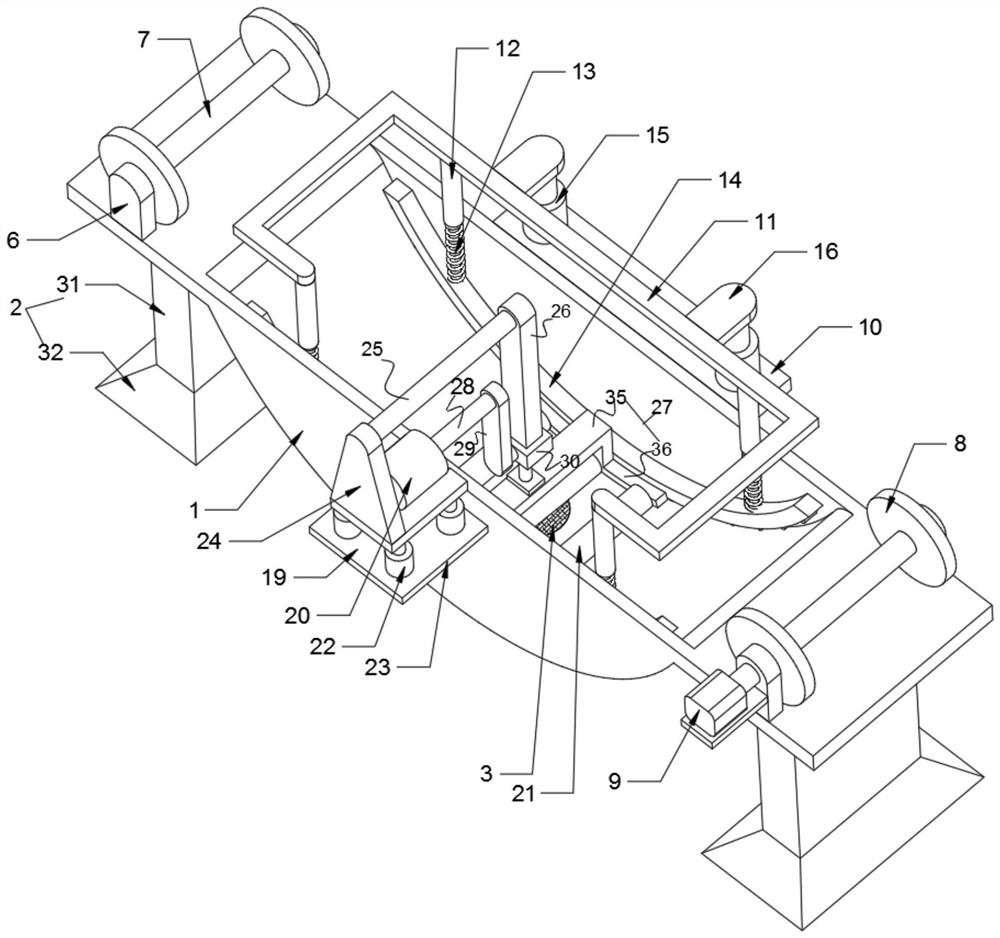

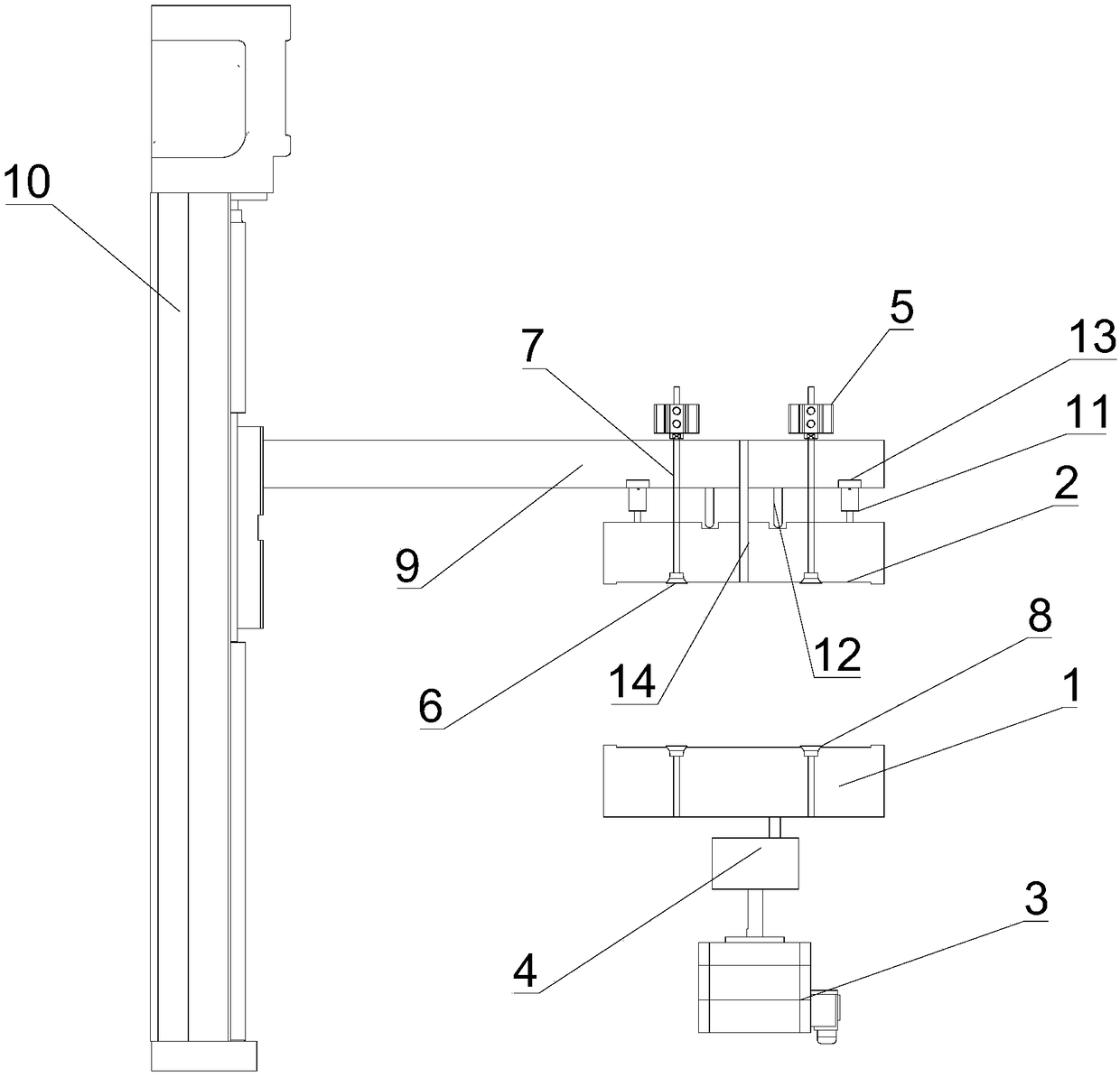

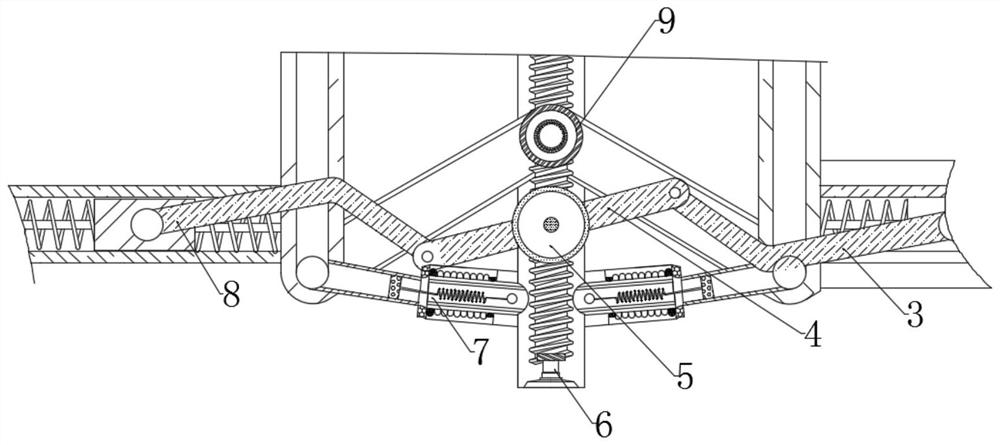

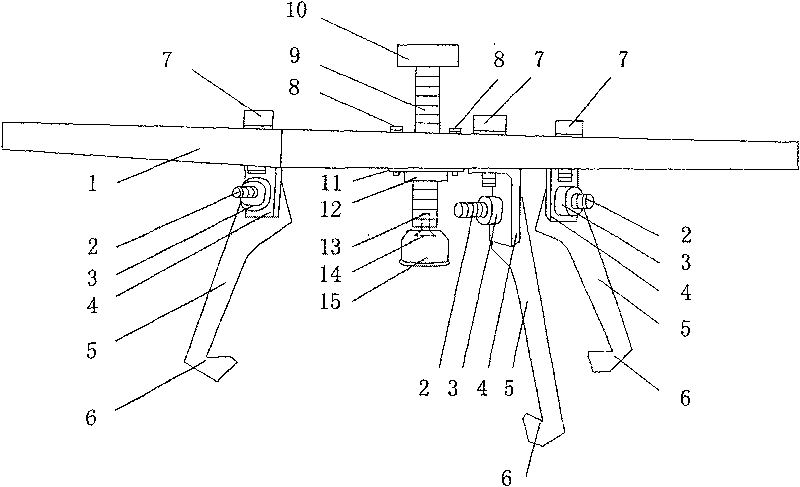

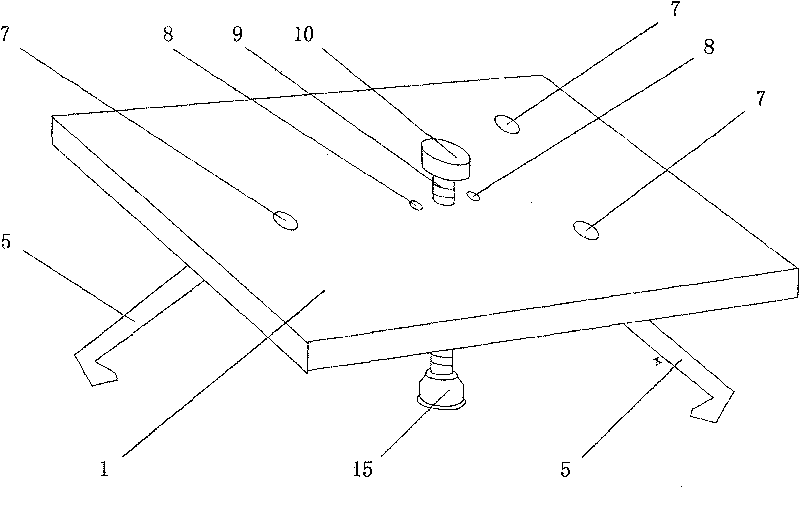

Movable grabhook apparatus for wireless test of vehicle dynamic property

InactiveCN101319965BEnables adjustable counterweightAdjust fitVehicle testingVehicle dynamicsEngineering

The invention discloses a movable grab hook device used for wirelessly testing the dynamic performances of a vehicle which includes a grab hook supporting plate, three movable grab hook mechanisms anda movable screw tightening mechanism that are mutually connected; the movable grab hook mechanisms are connected with the bottom part of the grab hook supporting plate in a triangle layout mode; themovable screw tightening mechanism is connected with the central part of the grab hook supporting plate and the outside of the movable screw tightening mechanism is surrounded by the grab hook supporting plate in a triangle layout mode. When in testing, a tested circuit board and a balancing weight additive plate are respectively, oppositely and fixedly arranged at the two ends of the plane of thegrab hook supporting plate; the hooks of the three movable grab hook mechanisms are respectively grabbed with the inner edge of a window hole in the metal hood cover of the hub of a vehicle tyre andfirmly grab the whole device by the rotating pressure of a large central movable screw to the metal hood cover of the hub. A testing platform which can run with the tyre is provided.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com