Method for optimizing processing uniformity of Bi2212 wire rod through gradient assembly

A technology of bi2212 and uniformity, which is applied in the field of wire processing, can solve the problems of poor synergistic deformation of wire rods, and achieve the effects of low cost, strong implementability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] Step 1, according to the conventional processing technology of Bi2212 wire, prepare Bi2212 secondary wire with silver ratio of 2.12, 2.02 and the same cross-sectional shape and size;

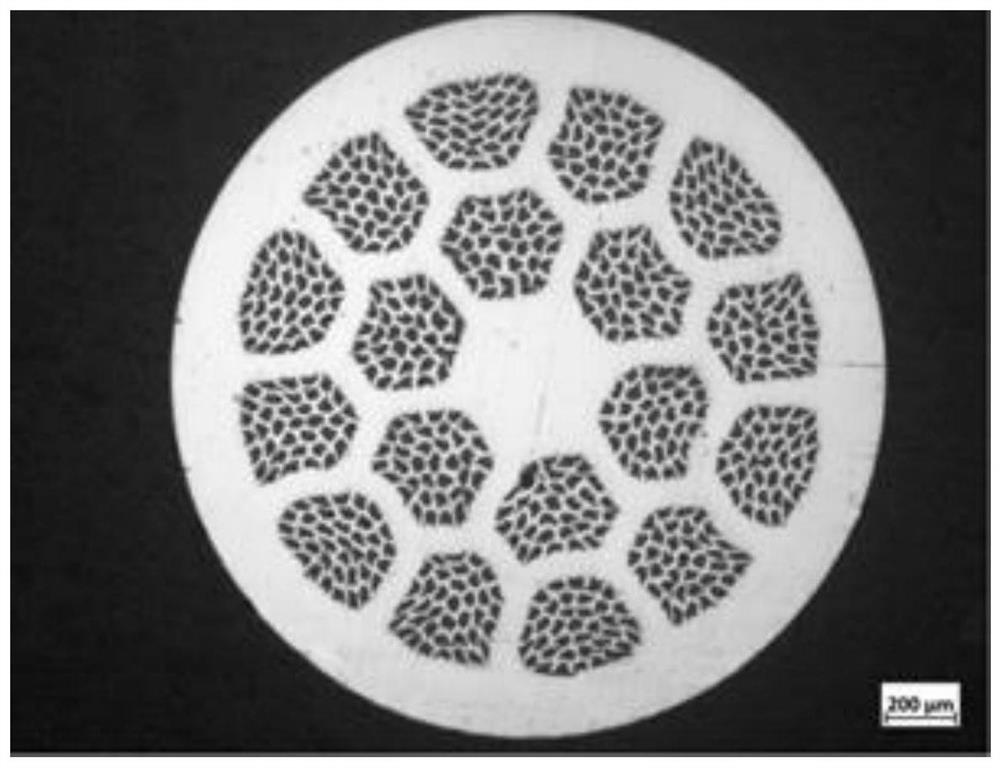

[0035] Step 2. Use 1 silver rod with the same cross-sectional shape and size as the Bi2212 secondary wire prepared in the first step as the inner core, and arrange 6 Bi2212 secondary wires with a silver-to-super ratio of 2.12 prepared in the first step. The outer periphery of the inner core forms an inner ring, and 12 Bi2212 secondary wires with a silver-to-super ratio of 2.02 prepared in step 1 are arranged on the outer periphery of the inner ring, and then the whole is put into the tertiary casing to obtain a secondary assembly composite;

[0036] In step 3, the secondary assembly composite obtained in step 2 is drawn for multiple times to obtain Bi2212 wire rod with a diameter of 2.02 mm.

Embodiment 2

[0044] This embodiment includes the following steps:

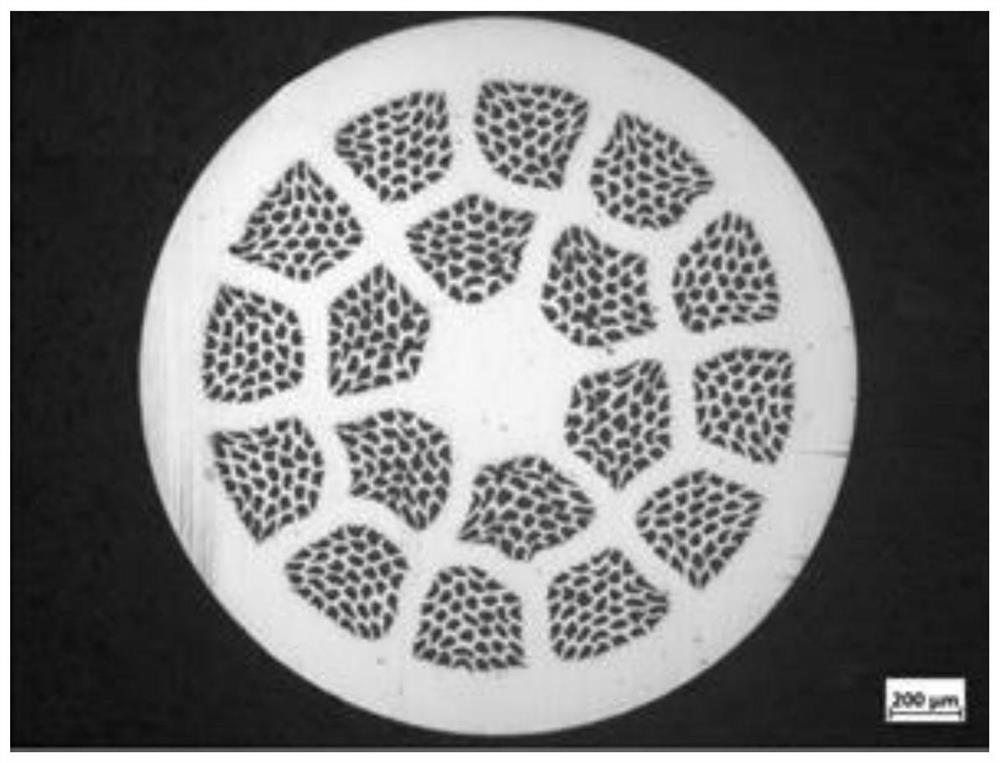

[0045] Step 1, according to the conventional processing technology of Bi2212 wire, prepare Bi2212 secondary wire with silver ratio of 2.25, 2.08 and the same cross-sectional shape and size;

[0046] Step 2. Use 1 silver rod with the same cross-sectional shape and size as the Bi2212 secondary wire prepared in the first step as the inner core, and arrange 6 Bi2212 secondary wires with a silver-to-super ratio of 2.25 prepared in the first step. The outer periphery of the inner core forms an inner ring, and 12 Bi2212 secondary wires with a silver-to-super ratio of 2.08 prepared in step 1 are arranged on the outer periphery of the inner ring, and then the whole is put into the tertiary casing to obtain a secondary assembly composite;

[0047] In step 3, the secondary assembly composite obtained in step 2 is drawn for several times to obtain Bi2212 wire rods with a diameter of 1.00 mm.

Embodiment 3

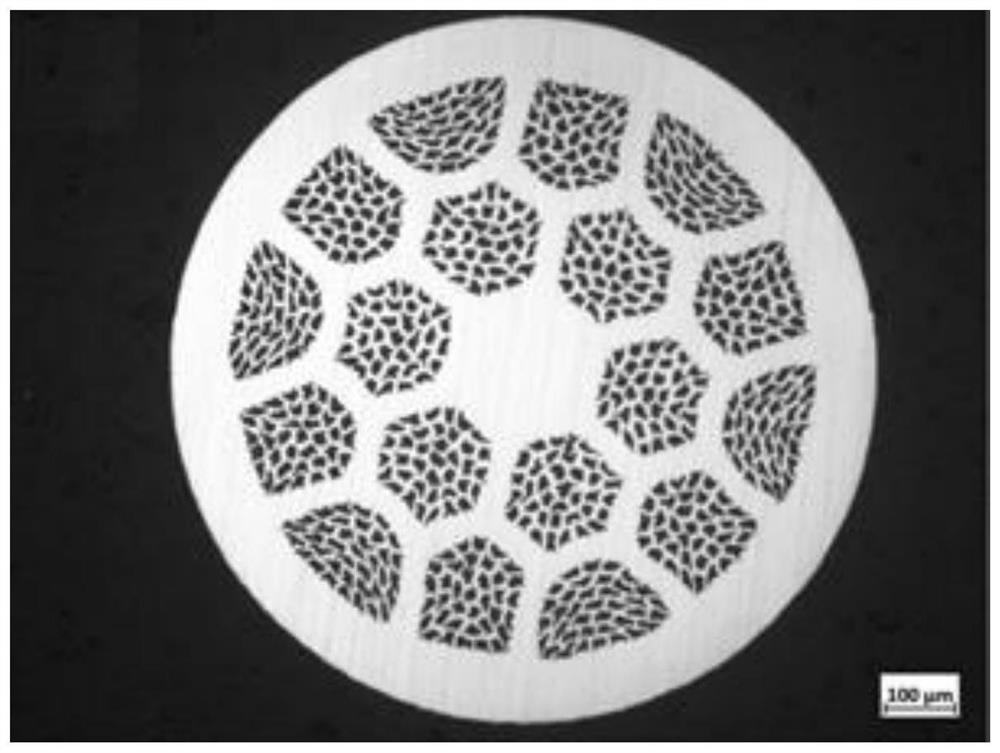

[0055] The difference between this embodiment and Embodiment 2 is that in step 3, a Bi2212 wire with a diameter of 0.81 mm is obtained by drawing for many times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com