Gravity automatic adjusting polishing device

A technology of automatic adjustment and polishing device, applied in grinding/polishing equipment, grinding machine, metal processing equipment, etc., can solve the problems of increasing labor cost and labor intensity, difficult to guarantee adjustment accuracy, uneven surface effect of zipper, etc., to achieve polishing The effect of good consistency, simple and convenient adhesion, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

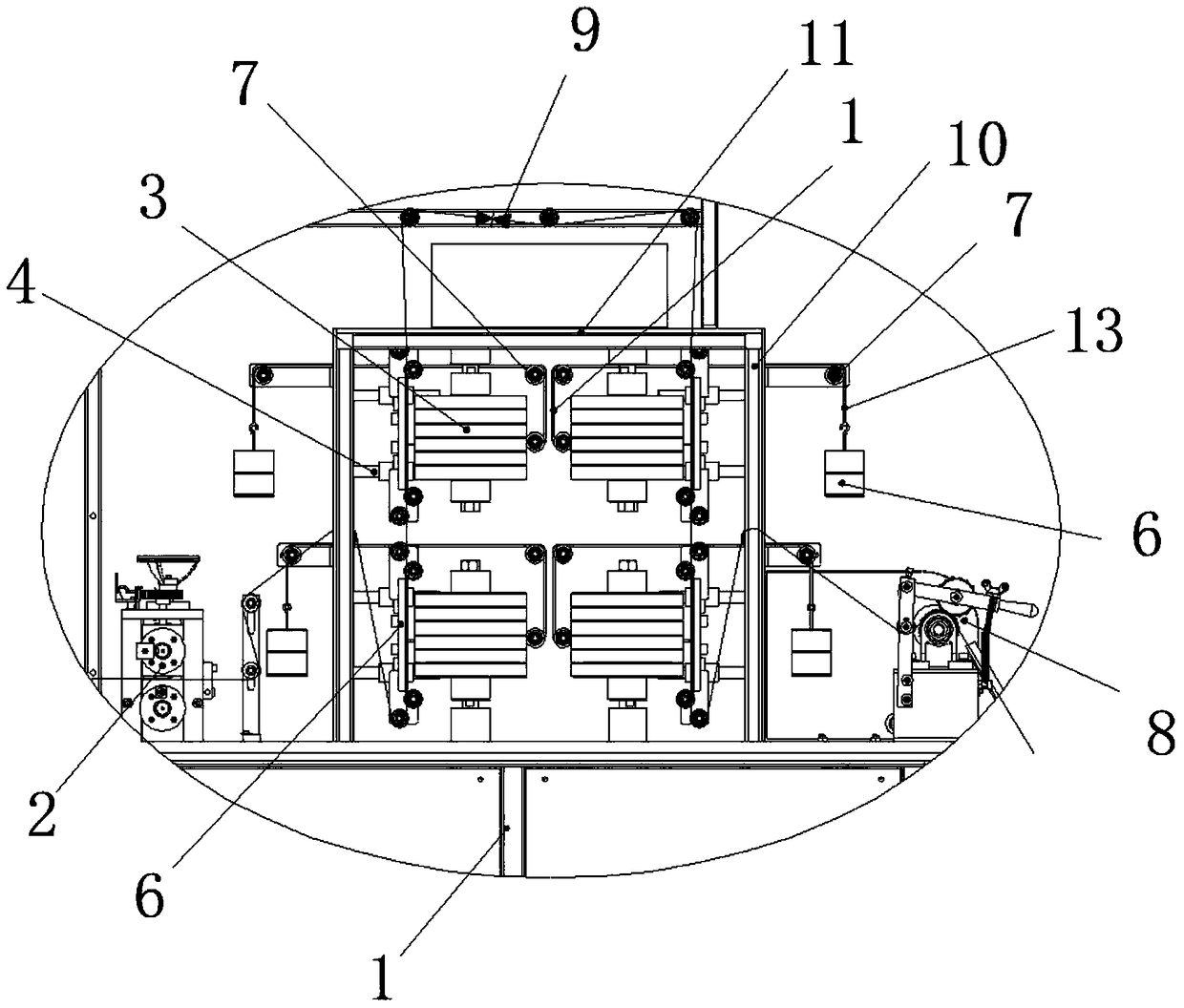

[0014] See attached figure 1 , the present invention comprises frame 1, and frame 1 is provided with feeding device 2, and described frame 1 is provided with two vertical members 10 and two transverse members 11, and vertical member 10 and transverse member 11 form A square structure, a plurality of fiber polishing wheels 3 are installed on the transverse member 11, a slide rail 4 is installed on the vertical members 10 on both sides of the square, and a polishing fixture 5 is installed on the slide rail 4, and the polishing fixture 5 can be mounted on the slide rail 4, move horizontally and laterally, a plurality of wire rope guide wheels 7 are also arranged in the square structure, and a bracket 12 is arranged on the outside of the vertical member 10 of the square structure, and the wire rope guide wheels 7 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com