Power source

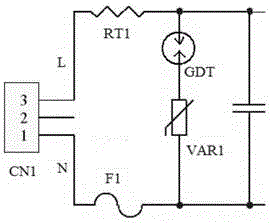

A power supply and roller technology, applied in the field of power supply, can solve problems such as subsequent circuit damage, unsatisfactory surge protection effect, nuclear explosion, etc., and achieve the effect of convenient replacement of rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Such as figure 1 As shown in the figure, a switching power supply with high surge protection level includes a resin tank and an upper roller and a lower roller arranged above the resin tank. , the right side of the lower roller is provided with a roller, the bracket is provided with a beam, one end of the beam is installed on the bracket, and the other end of the beam is connected to the roller; the beam is provided with a roller adjustment hole.

[0013] Adjustment holes are provided on the bracket, and the contact condition between the lower roller and the molding resin can be adjusted in time without adding molding resin.

[0014] A crossbeam is added to the bracket and a number of roller adjustment holes are opened on the crossbeam, which can adjust the contact tightness between the roller and the lower roller and the tension formed by the roller to the lower roller. It is connected with the bracket and can be replaced at any time .

[0015] There is a roller on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com