Multi-direction adjustable sealing device used for carling air passing chamber of grate cooler

A sealing device and ventilation chamber technology, which is applied to the sealing of the engine, the treatment of discharged materials, mechanical equipment, etc., can solve the problems of no wear compensation adjustment function, discounted sealing effect, etc., and achieve simple and clear structure, easy operation, The effect of saving space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

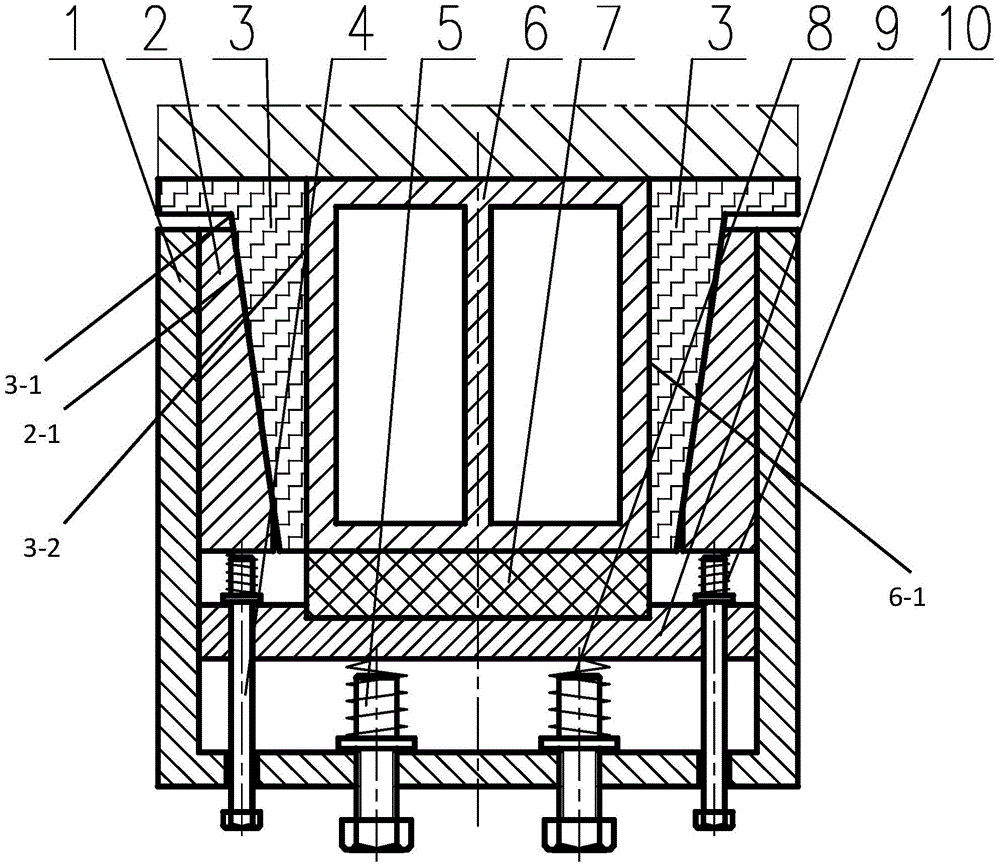

[0012] Such as figure 1 As shown, the present invention provides a multi-directional adjustable sealing device for the vent room of the longitudinal beam of the grate cooler, including a peripheral frame 1, a wedge block 2, a wedge seal 3, a long screw 4, a short screw 5, Movable parts 6, rectangular seals 7, compression spring one 8, adjustment plate 9, compression spring two 10; compression spring one 8 is set on the short screw rod 5 passing through the bottom of the peripheral frame 1 to apply compression to the adjustment plate 9 Force; the long screw rod 4 passes through the bottom of the peripheral frame 1 and the adjustment plate 9, and the compression spring 2 10 is sleeved on the long screw rod 4 to apply a compressive force to the wedge block 2; the rectangular seal 7 is located on the adjustment plate 9 and is connected with the movable part 6 The lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com