Method for detecting multiple technical indexes of turntable bearing by using detecting platform

A technology for turntable bearings and testing platforms, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as different detection methods, inconsistent bearing preload states in the detection environment, and no uniform standard for the accuracy of detection results. The detection method is simple and practical, and the effect of ensuring accuracy is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

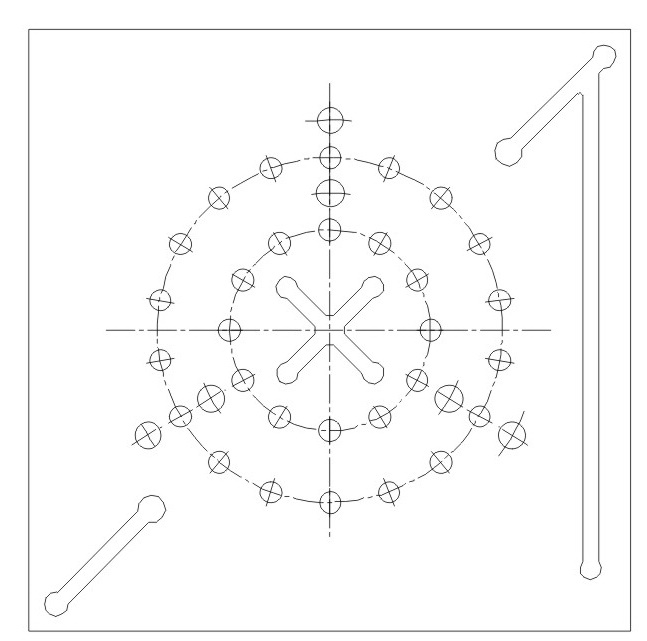

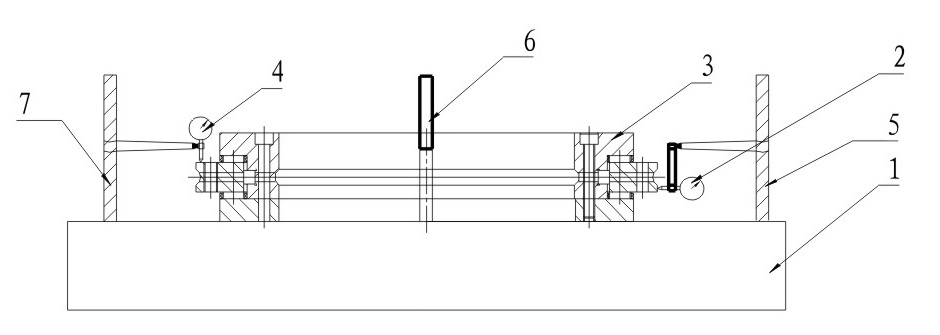

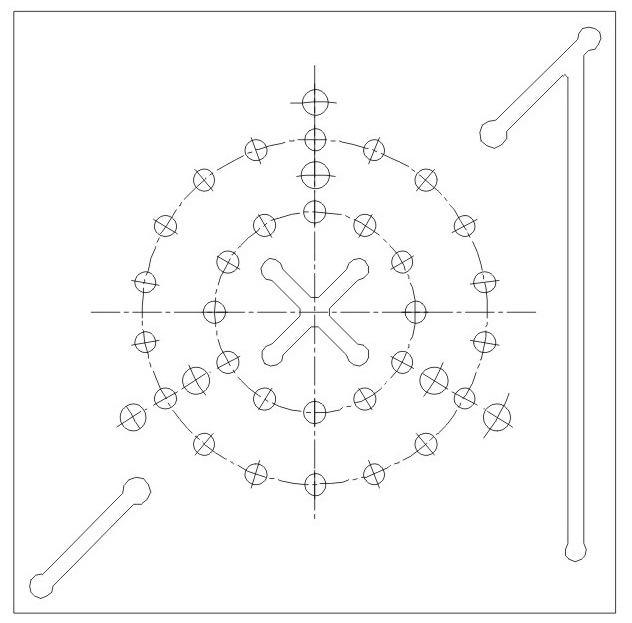

[0024] In order to clearly understand the detection method of the present invention, a brief description of the structure of the test object turntable bearing 3 of the present invention is given first.

[0025] In order to facilitate the installation of the outer ring of the turntable bearing 3, the inner ring of the turntable bearing 3 is composed of the inner ring of the raceway and the inner ring of the end cover. The connecting holes with the same hole diameter realize the fast connection between the inner ring of the raceway and the inner ring of the end cover through bolts. The radial end faces of the inner ring of the raceway and the inner ring of the end cover are connected with the two radial end faces of the outer ring through long needle rollers. The outer diameter of the outer ring is larger than that of the inner ring, and several screw holes are arranged on the radial end face of the outer ring. Both the inner ring and the outer ring have a radial end face and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com