Surface-mounting high-precision large-power NTC (Negative Temperature Coefficient) thermistor and making method thereof

A thermistor, surface mount technology, applied in the direction of resistors with negative temperature coefficient, resistors, resistor parts, etc., can solve the problems of poor thermal conductivity, poor heat dissipation effect, low precision of NTC thermistor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

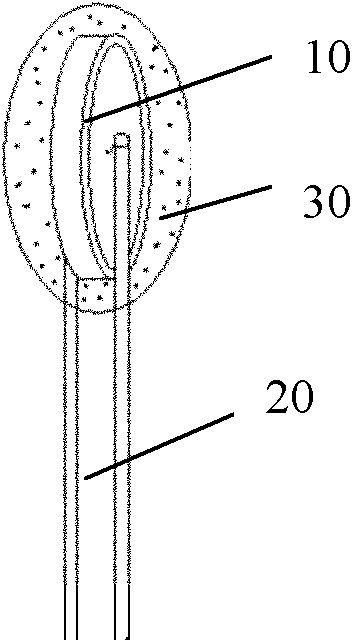

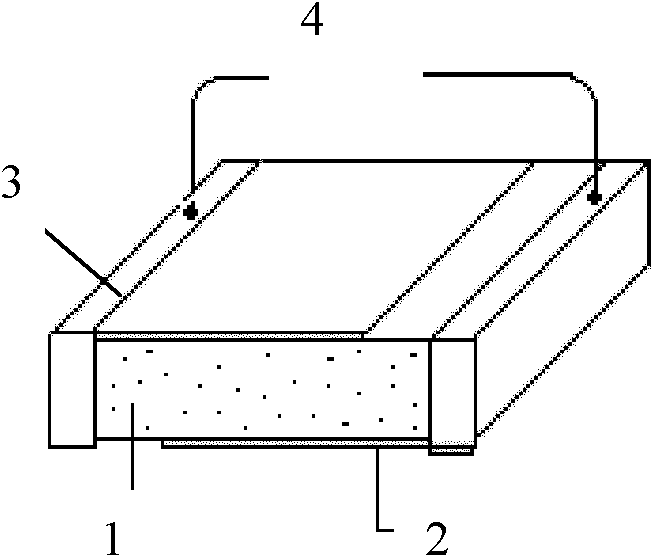

[0052] Such as figure 2 As shown, the surface-mounted high-power NTC thermistor of the present invention includes an NTC thermosensitive ceramic medium 1 of a chip structure, and the upper and lower surfaces of the NTC thermosensitive ceramic medium 1 are provided with a chip type from inside to outside. The surface electrode 2 and the thin glass encapsulation layer 3, the front and rear sides of the NTC heat-sensitive ceramic medium 1 are also provided with the glass encapsulation layer 3, and the two ends of the NTC heat-sensitive ceramic medium 1 of the chip structure are provided with terminal Electrode 4.

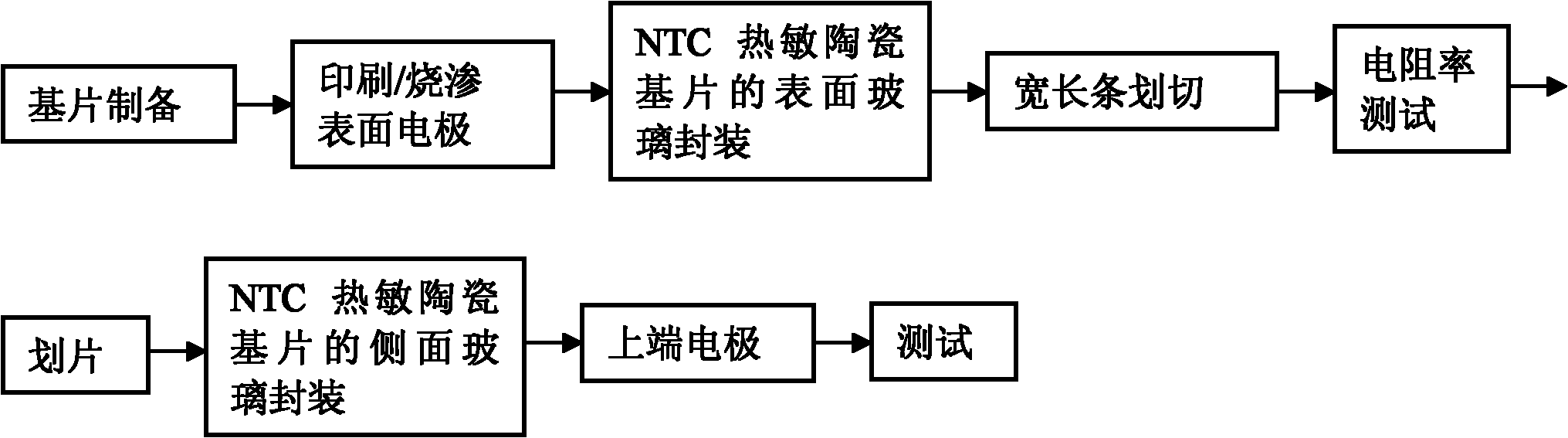

[0053] Such as image 3 Shown, the manufacture method of surface mounting high-precision high-power NTC thermistor of the present invention, its concrete steps are: (1) substrate preparation: carry out NTC thermosensitive ceramic substrate to make;

[0054] (2) Printing / fire-infiltration surface electrodes: print electrodes on the surface of the NTC thermosensitive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com