Gas discharge tube with shielded ceramic sheet

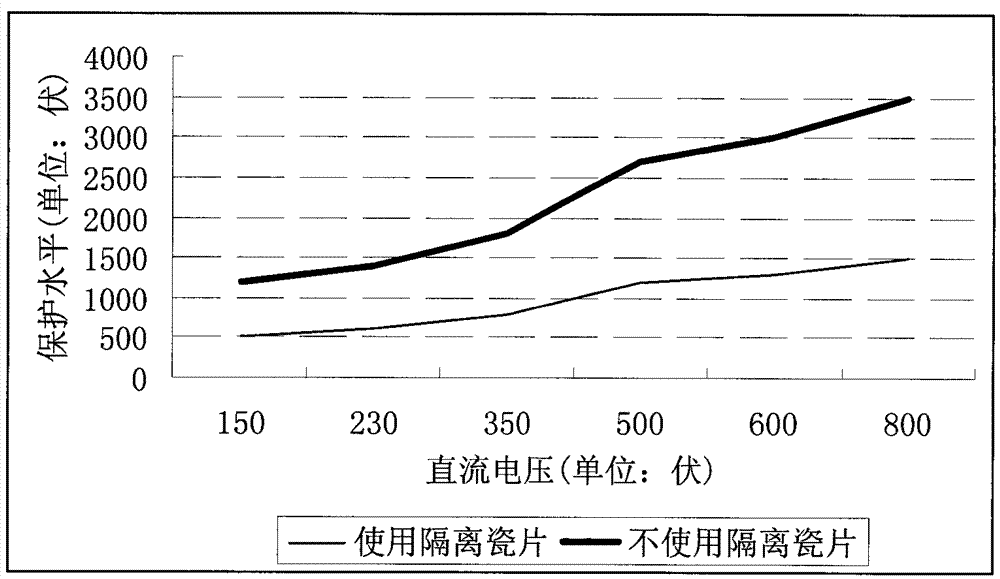

A technology of gas discharge tubes and ceramic tubes, applied in the direction of cold cathode tubes, solid cathode components, etc., can solve the problems of high current density, the width and length of the conductive strip are not an effective solution, large current, etc., and achieve the goal of reducing the protection level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

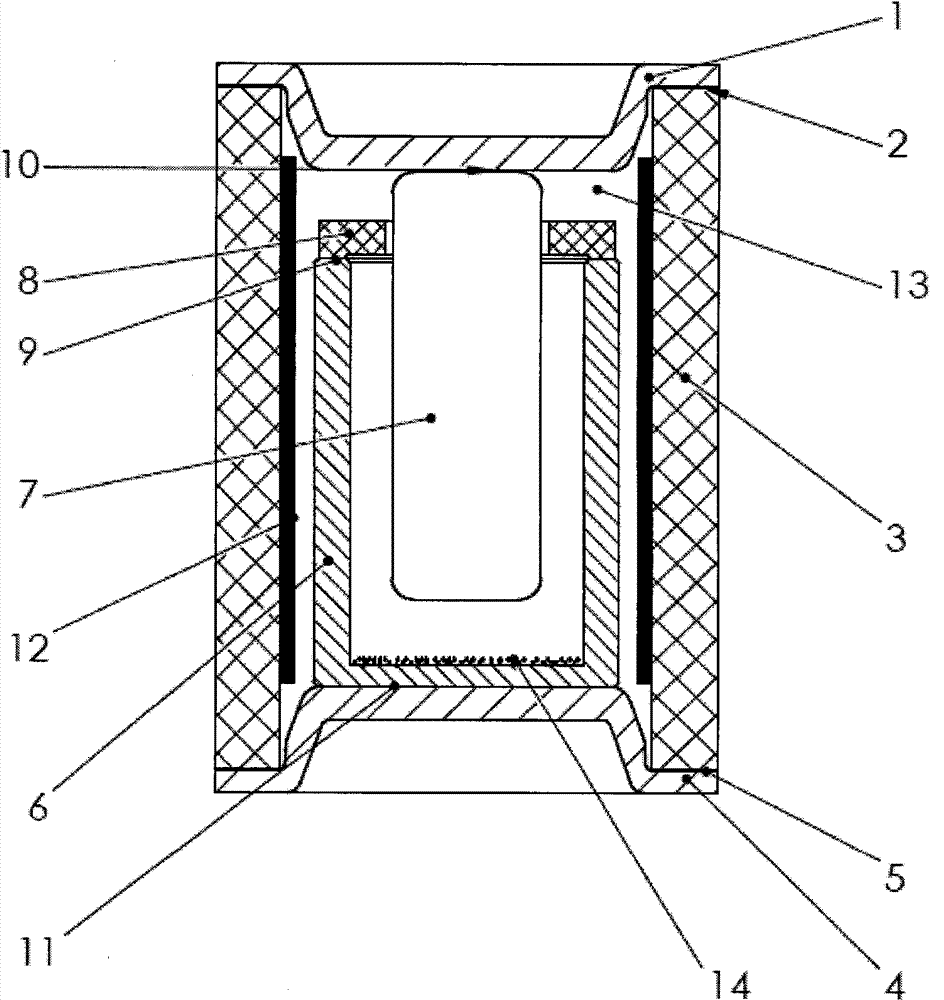

[0010] The present invention adopts the following structure: a gas discharge tube with a shielding ceramic sheet, including a ceramic tube 3, a side electrode 1 at the upper end of the ceramic tube 3, and a lower electrode 4 at the lower end, and a conductive strip 12 is arranged on the inner wall of the ceramic tube 3, The inner cavity of the ceramic tube 3 is filled with an inert gas 13, the electronic powder 14 is placed at the bottom of the tube electrode 6, the column electrode 7 is placed in the tube electrode 6, and a shielding ceramic sheet 8 is welded on the open end of the tube electrode 6.

[0011] In the present invention, the side electrode 1 and the column electrode 7 are welded together at 900±30° C. through the silver-copper solder 10; It is sealed into one body at 30°C; the conductive strip 12 is made of 4H lead core, and the inner wall of the ceramic tube 3 is drawn; the ceramic tube 3 is welded with the side electrode 1 and the bottom electrode 4 by silver-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com