Method for Identifying Pipette Configurations for Assembly Processes

A technology of assembly process, pipette, applied in the direction of electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

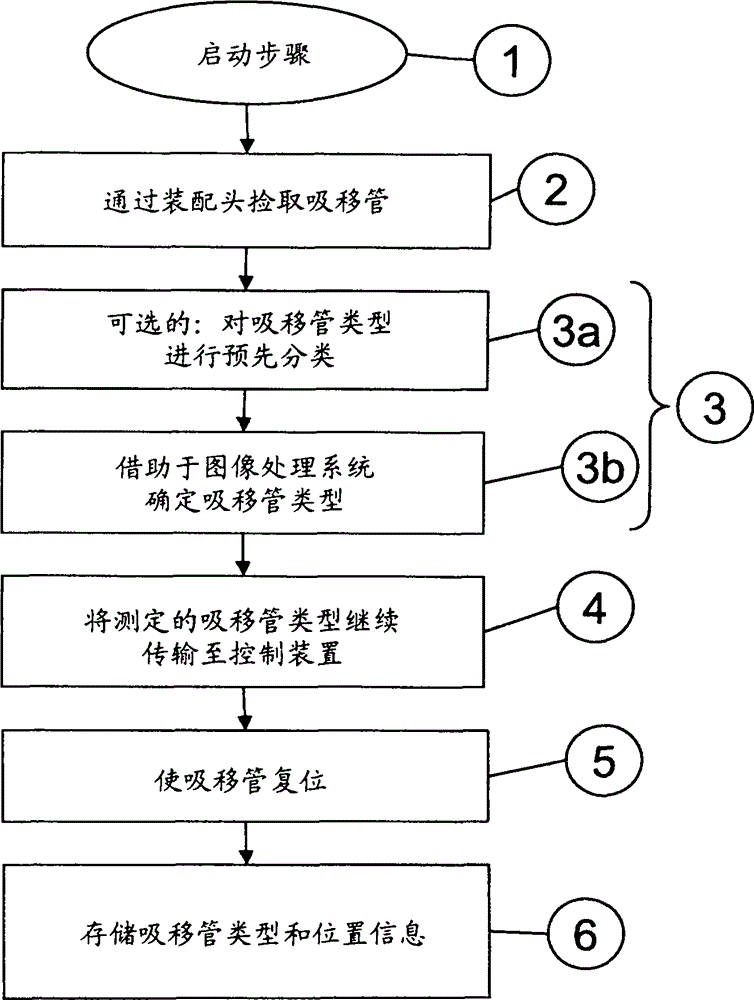

[0023] figure 1 An exemplary flow chart of a method according to the invention for detecting a pipette configuration for an assembly process in an assembly device is schematically shown. Pipettes for assembly of substrates or printed circuit boards are provided in the pipette changer for production. Pipettes with different pipette types are used corresponding to the components to be assembled. The pipette types are distinguished, for example, on the basis of different lengths of the pipettes, different air flows and / or different geometrical features, in particular of the end faces.

[0024] The method according to the invention is carried out prior to assembling the substrate with electronic components. The method according to the invention begins with a start-up step 1 . In a second method step 2, the pipettes arranged in the pipette changer are picked up by the assembly head of the assembly device and mounted on this assembly head.

[0025] In a third method step 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com