Identification card

a technology of identification cards and identification plates, applied in the field of identification cards, can solve the problems that the identification material thus produced should be susceptible to lamination in conventional lamination equipment, and achieve the effect of increasing public awareness and positive identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

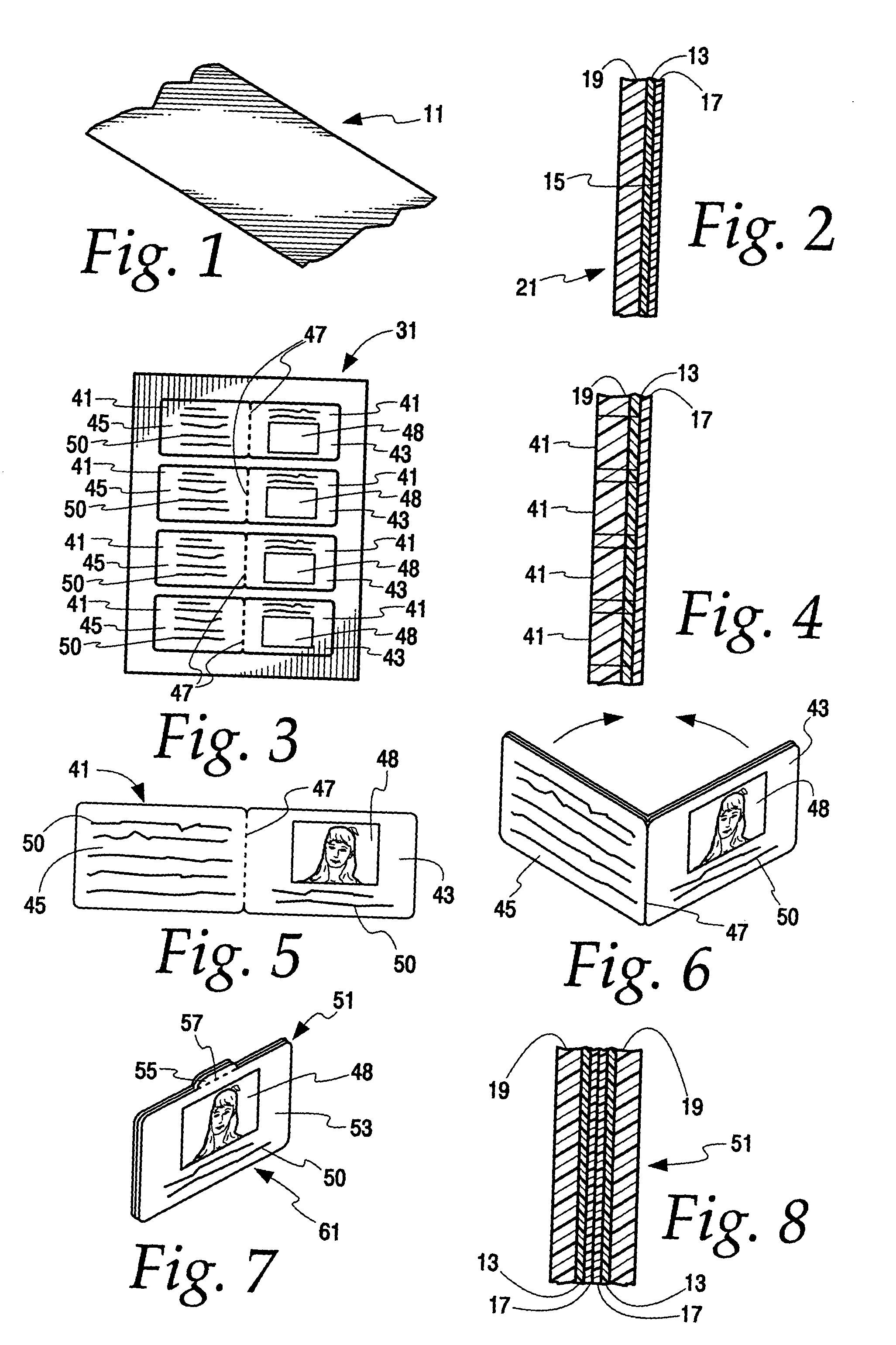

[0018]FIG. 1 of the drawing shows a continuous sheet 11 formed by extruding a heat sensitive polyethylene adhesive 13 onto one side 15 of a release film 17, as shown in FIG. 2. A porous, printable polyolefin film 19, such as the film sold under the trademark TESLIN by PPG Industries, Inc. of Pittsburgh, Pa., is laminated to the extruded polyethylene 13 to form a laminate sheet 21 with the polyethylene adhesive transferring to the polyolefin film.

[0019] The laminate sheet 21 is cut into discrete sheets 31 which may be of letter or A-4 size or other dimensions suitable for use in conventional computer controlled printing printers such as laser printers, inkjet printers or ALPS microdry color printers. The discrete sheets 31 can then be die cut through the layers of polyolefin film 19 and polyethylene film 13 to form rectangular shaped bodies 41 suitable for receiving photos and text. Each body 41 consists of a pair of panels 43 and 45 connected by a fold line 47 which may be perforat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| heat sensitive | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com