Casting guiding device

A guiding device and casting flow technology, applied in the field of metal casting equipment, can solve the problems of high casting speed, poor side bulging effect, easy outward deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

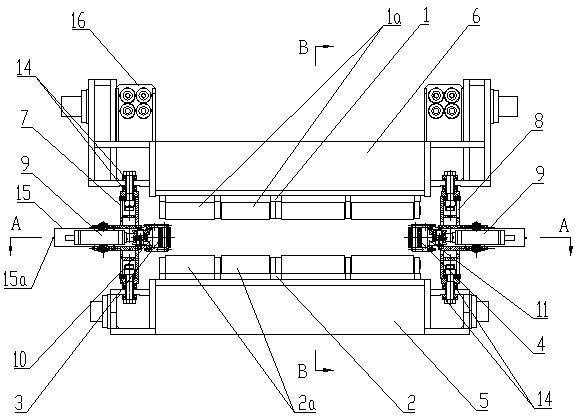

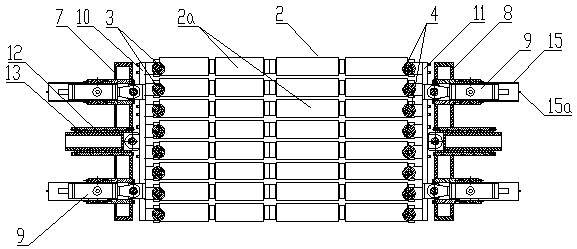

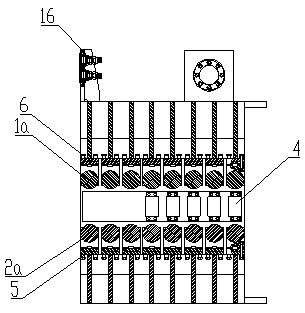

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A-A sectional view of, image 3 for figure 1 B-B sectional view of the figure, as shown in the figure: the casting strand guiding device of this embodiment includes a wide-surface guiding device and a side guiding device, and the wide-surface guiding device includes multiple rows of outer arc wide-surface roller rows 1 arranged side by side along the casting strand direction and the inner arc wide surface roll row 2, the side guide device includes multiple rows of left side rolls 3 and right side rolls 4 arranged side by side along the direction of the casting stream, the outer arc wide surface roll row 1, the inner arc wide surface The roll row 2, the left side roll 3 and the right side roll 4 together form a strand guiding channel. After the slab comes out of the crystallizer, under the restriction of the casting strand guiding channel, even if the casting speed is high a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com