Laser helically rotating optical module applied to laser process equipment

A technology of laser processing and optical modules, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of low processing efficiency, small diameter-to-depth ratio, and inability to process inverted taper holes, etc., to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

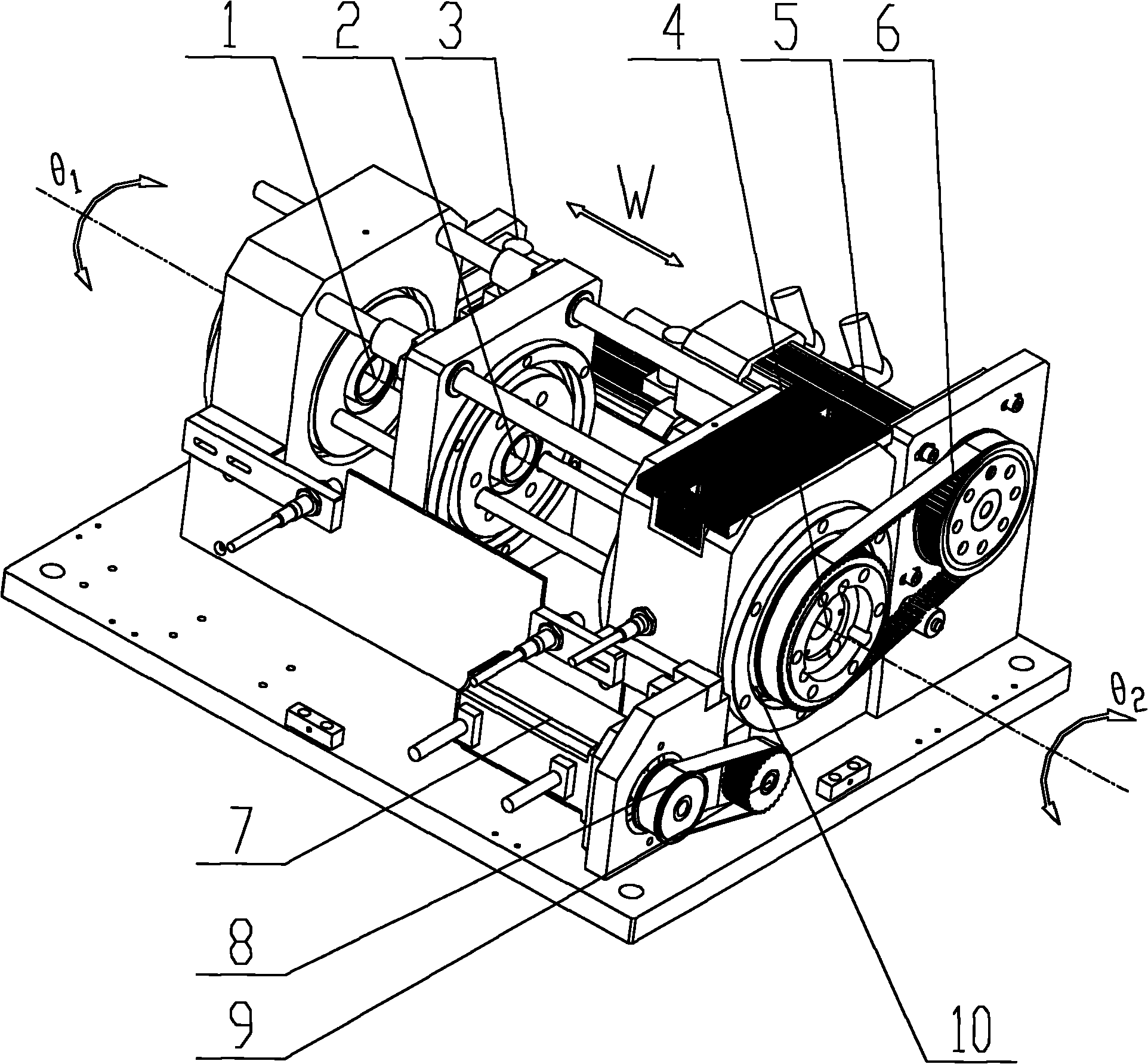

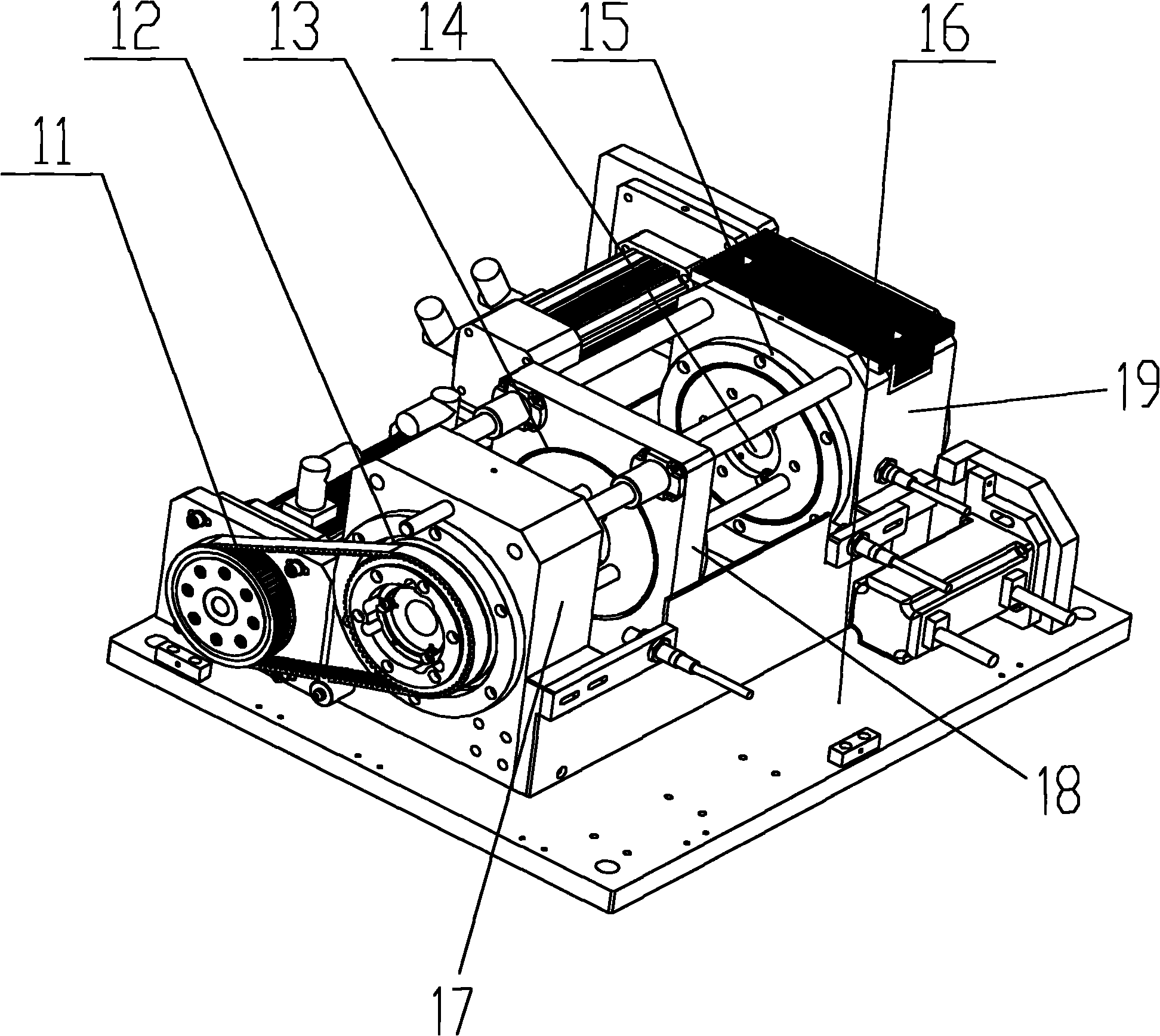

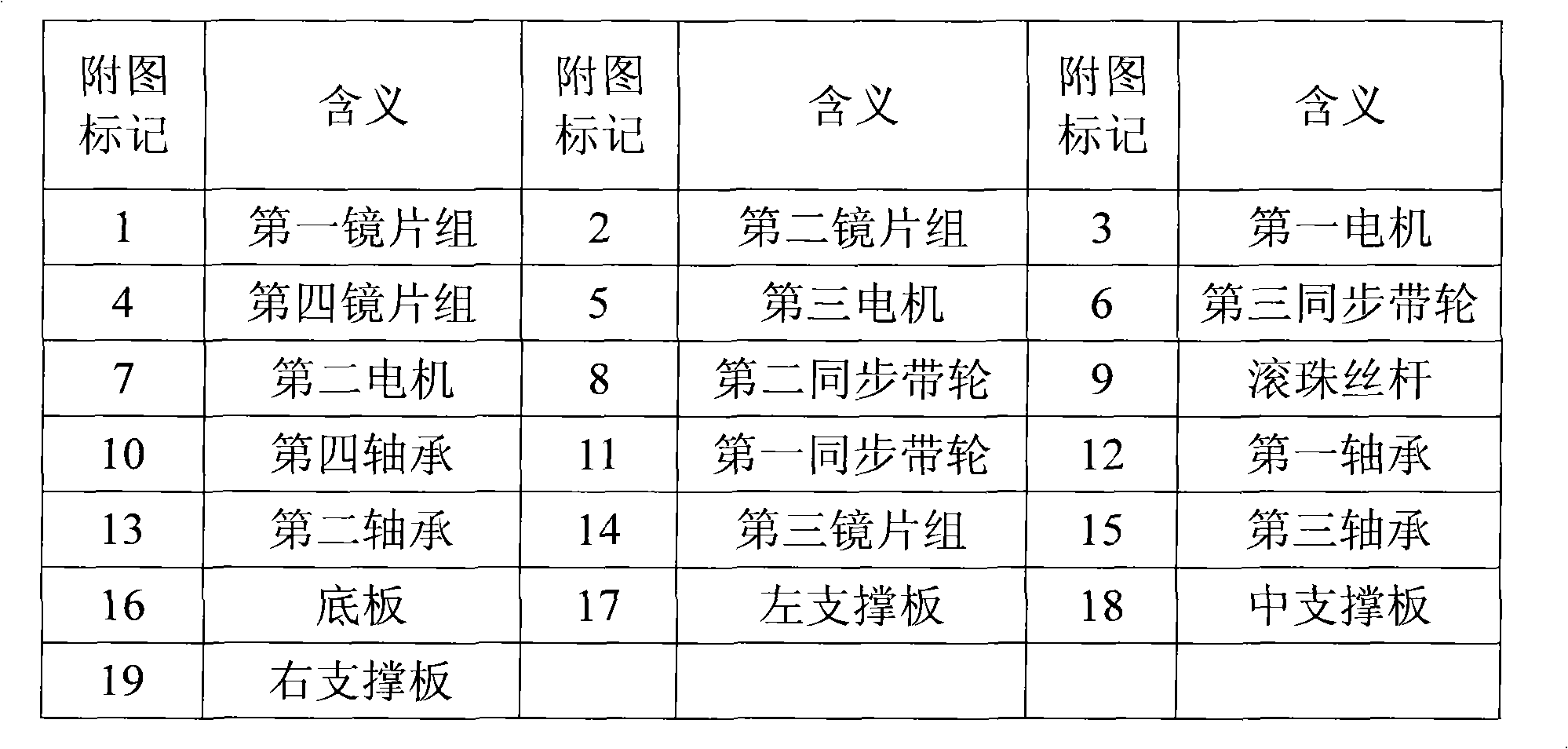

[0014] Such as figure 1 , figure 2 As shown, the laser spiral rotation optical module applied to laser processing equipment includes multiple sets of lens groups, left support plate 17, middle support plate 18 and right support plate 19, left support plate 17, middle support plate 18 and right support plate 19 are installed on the bottom plate 16 at intervals in parallel, the first bearing 12 is installed in the left support plate 17, the first lens group 1 is installed inside the first bearing 12, the second bearing 13 is installed in the middle support plate 18, the second bearing 13, the second lens group 2 is installed inside, and the third bearing 15 and the fourth bearing 10, which are independent of each other, are installed in the right support plate 19, the third lens group 14 is installed inside the third bearing 15, and the third lens group 14 is installed inside the fourth bearing 10. Four lens groups 4, the first bearing 12 and the third bearing 15 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com