Special machine for motor rotor welding

A technology for motor rotors and specialized machines, applied in the field of specialized machines, can solve the problems of unstable performance, low welding accuracy, slow speed, etc., and achieve the effects of stable speed, stable welding performance, and high control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

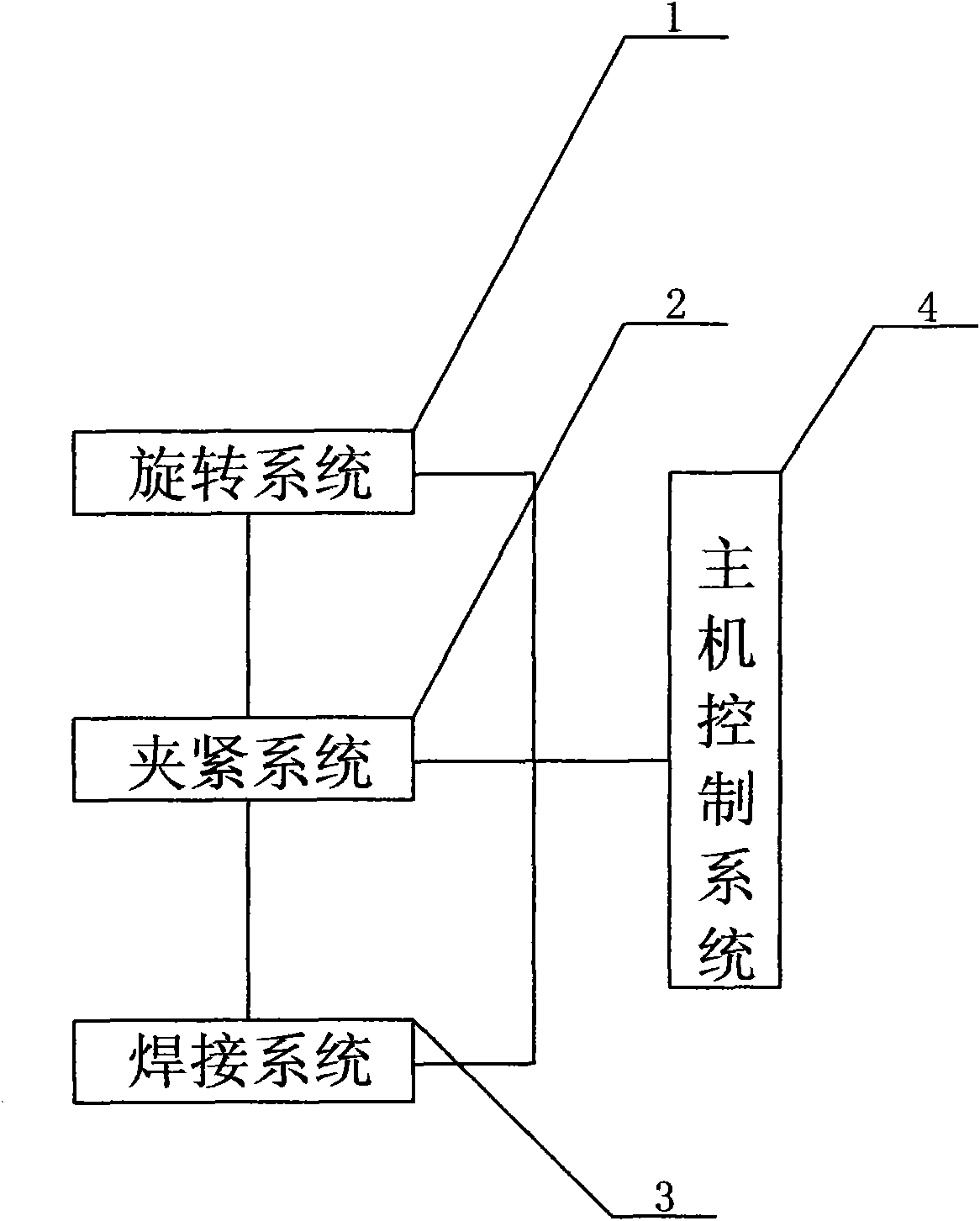

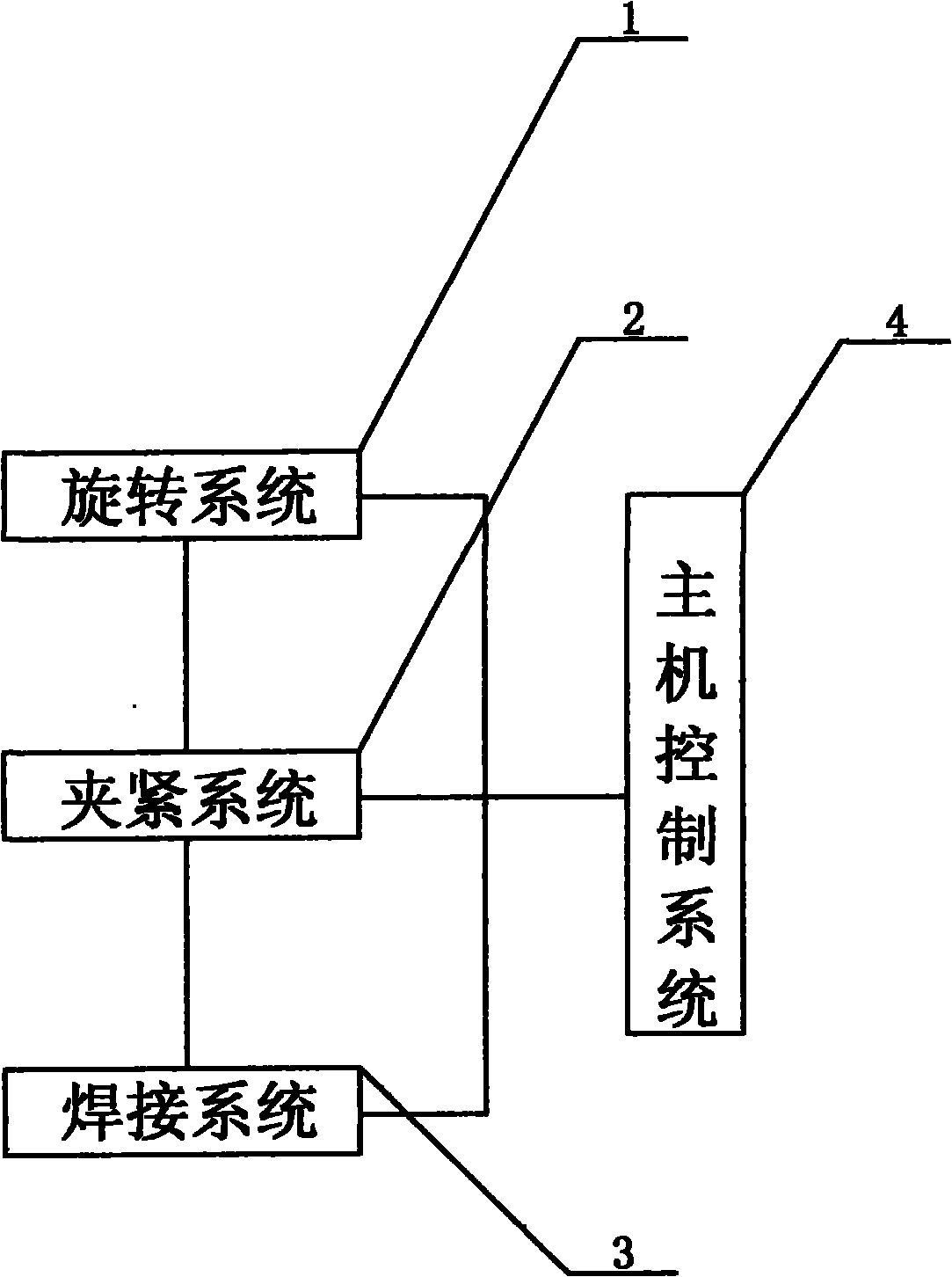

[0011] see figure 1 , the specific embodiment adopts the following technical scheme: it includes a rotating system 1, a clamping system 2, a welding system 3 and a host control system 4; the rotating system 1 is connected with the clamping system 2, and the clamping system 2 is connected with the welding system 3 The rotating system 1, the clamping system 2 and the welding system 3 are connected with the host control system 4 at the same time.

[0012] This specific implementation mode can realize man-machine dialogue, has high control precision, stable speed, and ensures stable welding performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com