Anti-reversing device for hoisting machine

A hoist, anti-reversal technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of safety hazards for maintenance personnel, damage to the equipment itself and the geared motor, and no anti-reverse device, etc. Achieve the effects of long practical life, simple structure and anti-reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

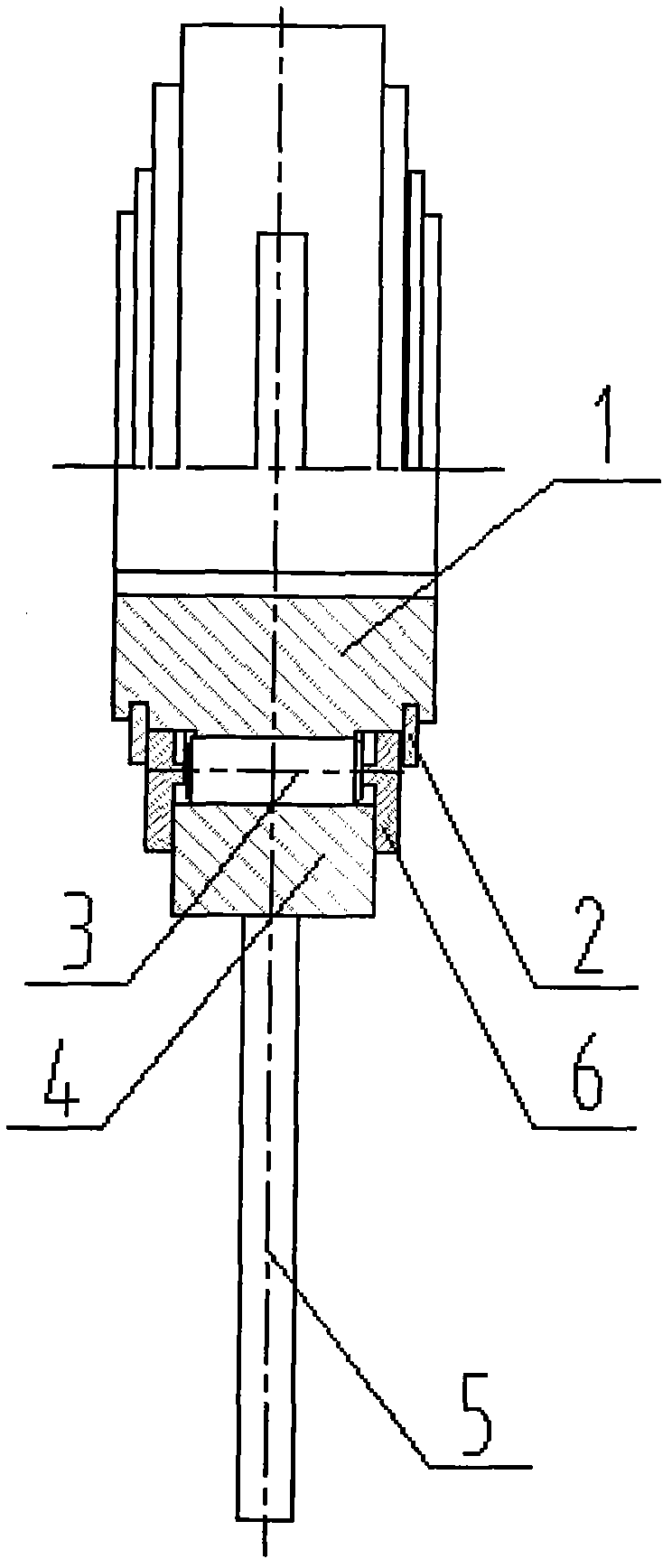

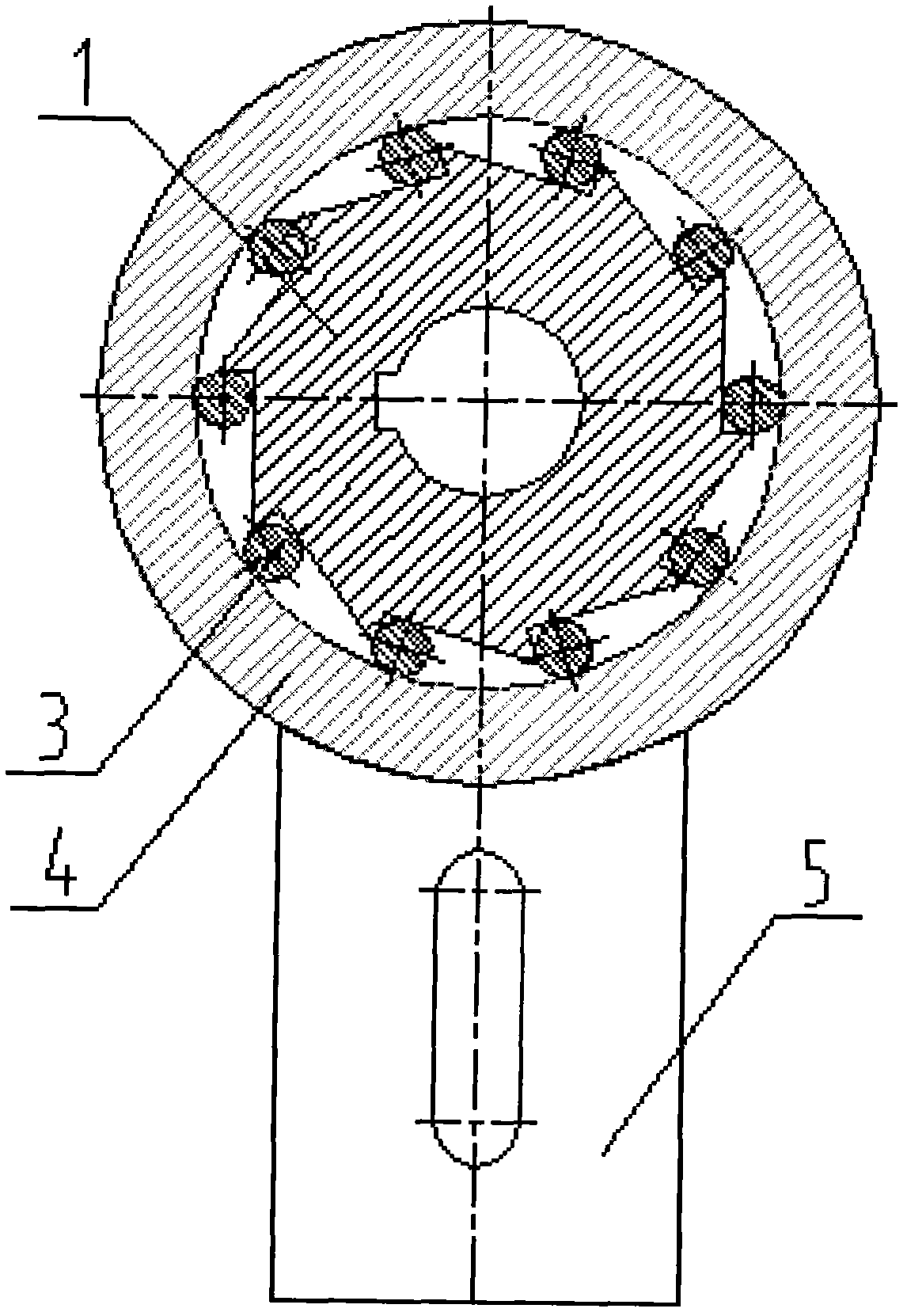

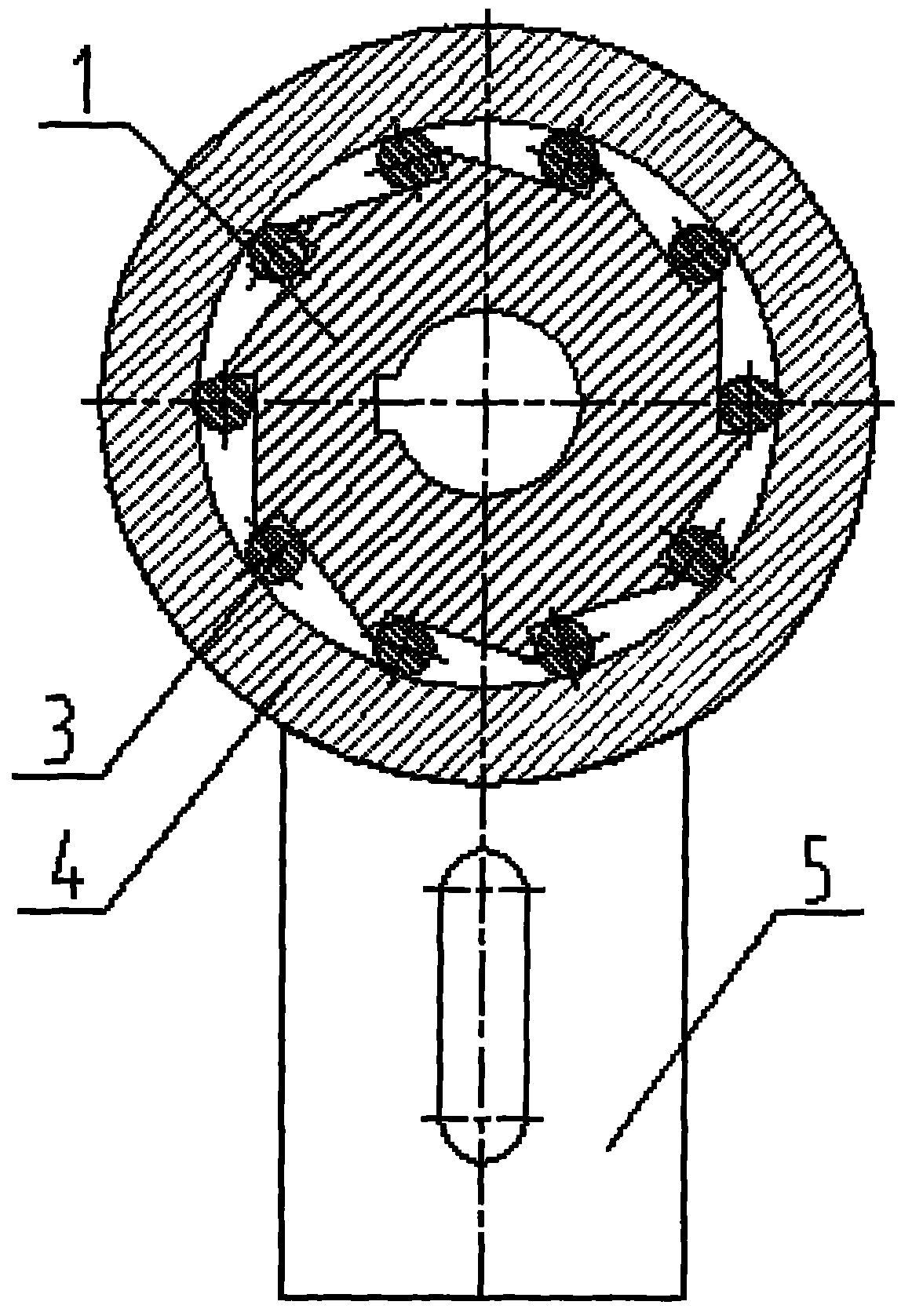

[0017] combine figure 1 and figure 2 , the present invention mainly includes a non-return inner ring 1 , a non-return roller 3 and a non-return outer ring 4 . Among them, the non-return inner ring 1 is installed on the drive shaft of the hoist, and there are several wedge-shaped grooves on the non-return inner ring 1, and the anti-return roller 3 is installed in the wedge-shaped groove between the non-return inner ring 1 and the non-return outer ring 4. , with non-return retaining ring 6 and shaft retaining ring 2 on both sides to position the non-return roller 3 in the axial direction, and at the same time restrict the non-return roller 3 in the wedge-shaped groove, and the non-return outer ring 4 is welded on the non-return positioning plate 5, there are elongated holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com