Encapsulating structure and encapsulating method of optical fiber combiner

A packaging structure and beam combiner technology, which is applied in optics, instruments, optical components, etc., can solve the problems of poor heat dissipation effect and poor long-term stability, and achieve high heat dissipation reliability, good stability, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

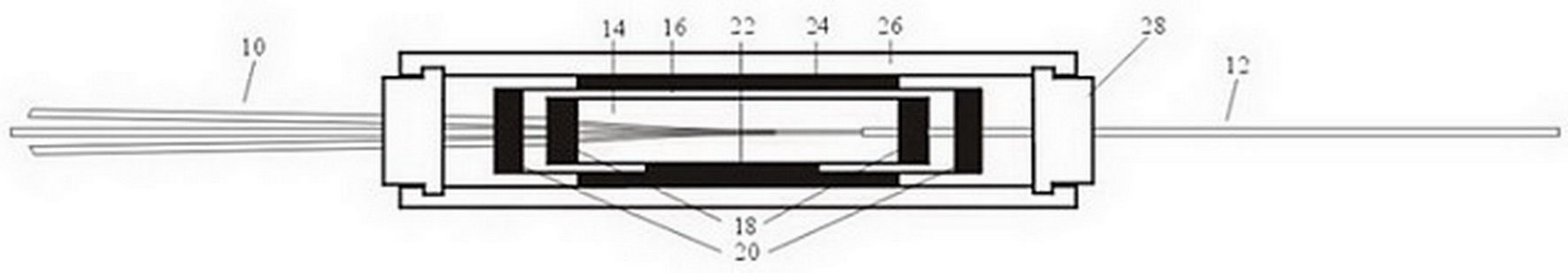

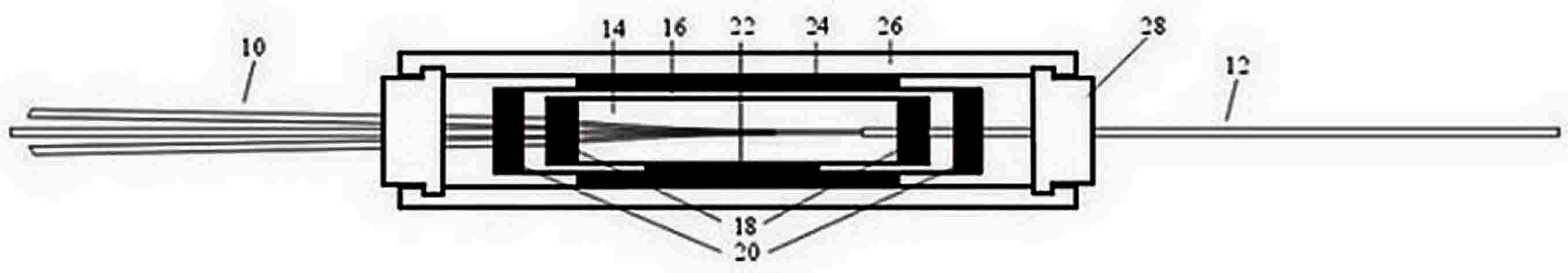

[0015] figure 1 The packaging structure of the beam combiner of the present invention is shown, including: a beam combiner; a substrate 14, on which the beam combiner is packaged, and a piece of glue 18 is used at both ends to fix the optical fibers; a round tube 16, the beam combiner is installed The substrate 14 is put into the round tube, the two ends of the round tube are sealed with two layers of glue 20, and the substrate and the round tube are bonded with the bottom glue 22; a metal box 26, the round tube 16 is sealed in the metal box with three layers of glue 24 Inside the box, the input optical fiber 10 and the output optical fiber 12 of the beam combiner protrude from the two ends of the metal box 26, and the two ends of the metal box are inserted with rubber caps 28 for protecting the optical fibers.

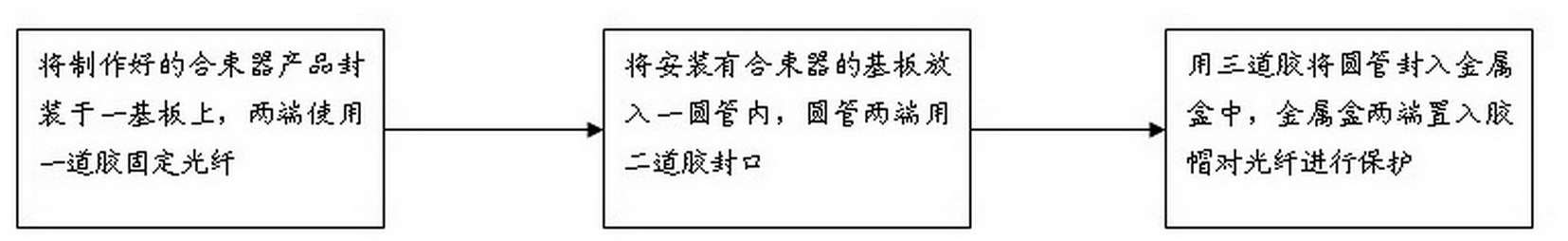

[0016] figure 2 It is the packaging flow chart of the method of the present invention, which specifically includes the following steps: first package the manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com