Sports combined brassiere mold cup and manufacture process thereof

A mold cup and bra technology, applied in bras, clothing, bras and other directions, can solve the problems of not achieving decompression, shock absorption, prone to indentation, unsuitable wearing, etc., and achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

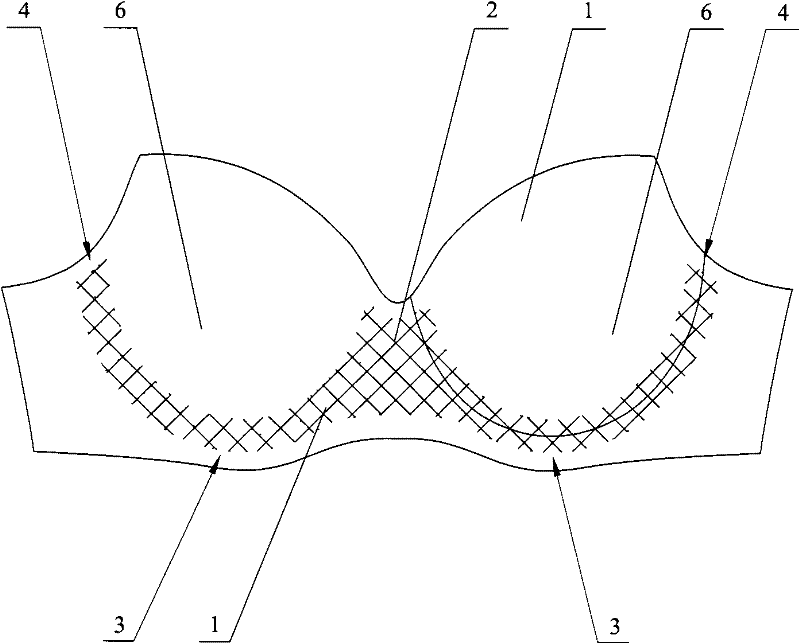

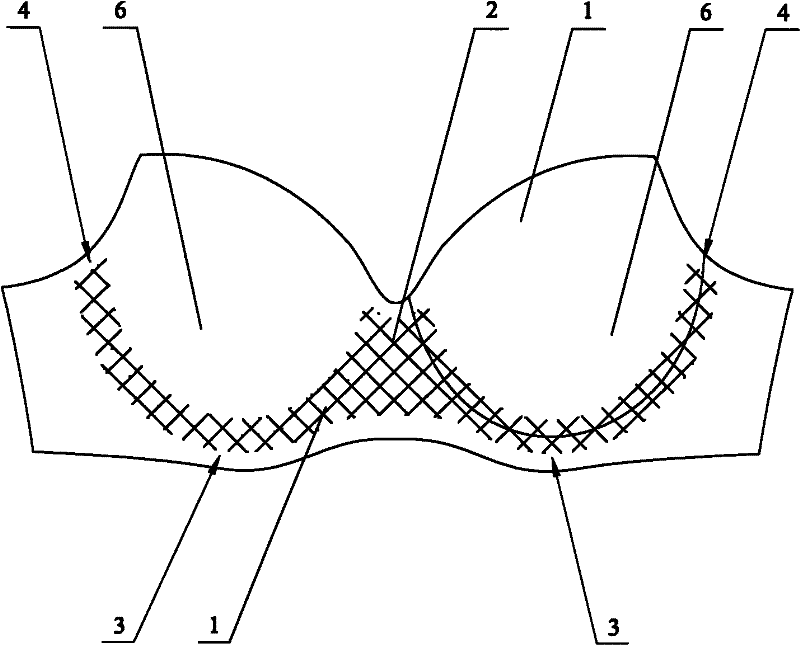

[0022] Embodiment one: see attached figure 1 shown.

[0023] A sports one-piece bra mold cup, comprising an integrated mold cup body 1, the middle position of the mold cup body 1 is the center position 2, the mold cup body 1 includes a lower bowl circumference 3, a bowl side 4, and the bottom of the lower bowl circumference 3 An arc-shaped support portion 5 is provided, and the support portion 5 extends downward from the bowl side 4 along the lower bowl circumference 3. The support portion 5 is in an integrated “W” shape, and the support portion 5 is made of sizing yarn.

[0024] The top of the supporting portion 5 is tilted toward the bowl side 4, and an elliptical cartridge 6 is provided.

[0025] A manufacturing process of a sports one-piece bra mold cup, comprising the following steps:

[0026] (1) After laminating the fabric and the sponge, cut out the upper layer and the lower layer;

[0027] (2) Use a cotton cutting board to clean the sponge to form a Jiamei core 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com