Waste pole breaking device for recycling reinforcing steel bar

A recovery device and crushing device technology, applied in grain processing, etc., can solve problems such as unsafe work, low work efficiency, and high labor intensity, and achieve the effects of cleaning, convenient operation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below will combine specific embodiment and appended Figure 1-5 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

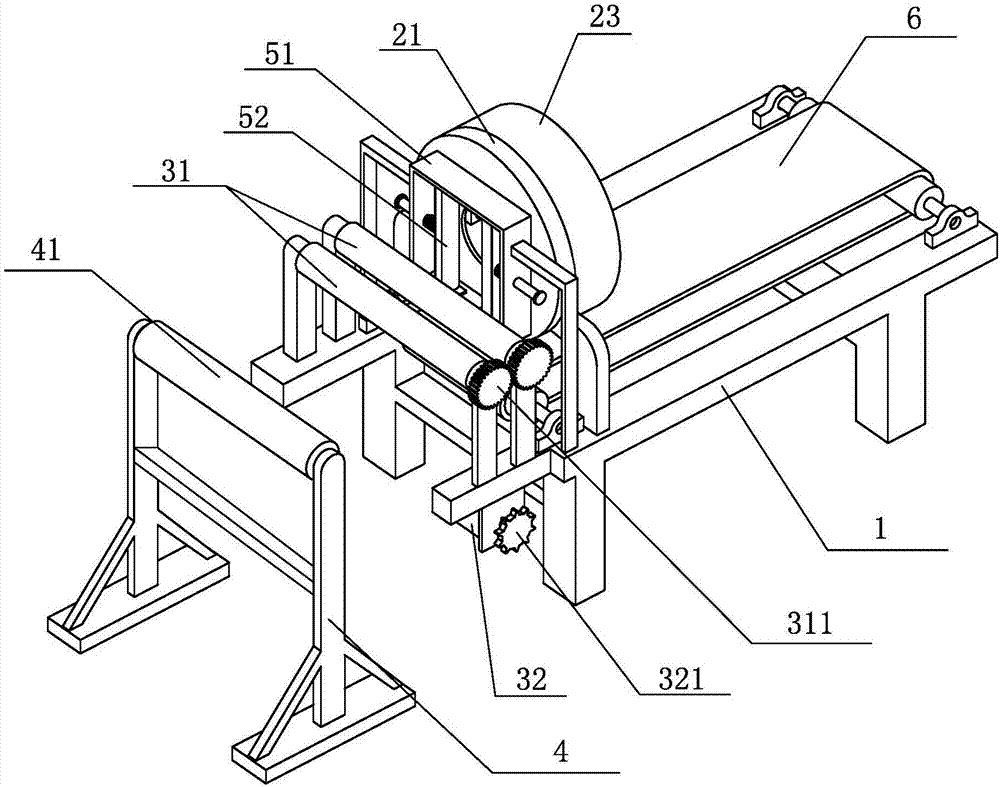

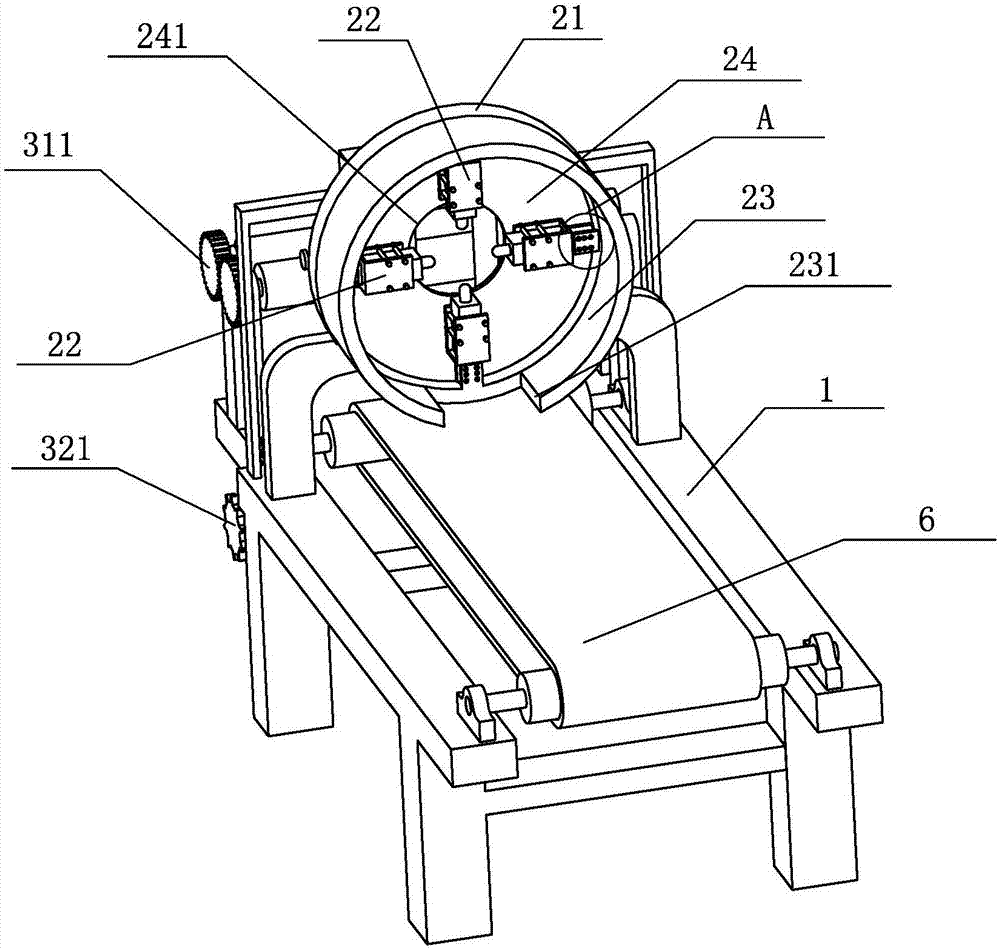

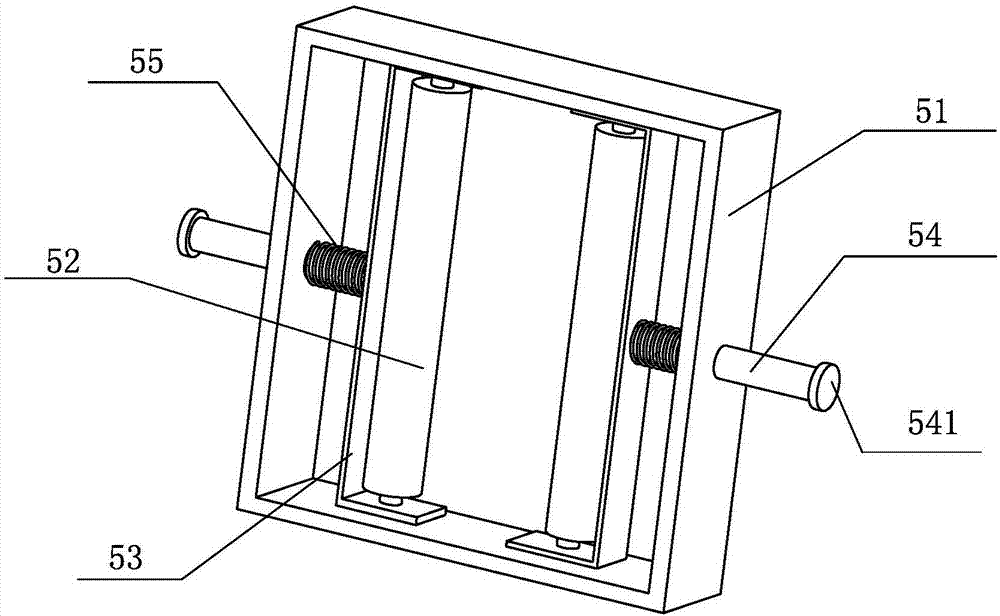

[0020] The invention provides a recycling device for broken steel bars of waste electric poles (such as figure 1 shown), including a complete machine support 1, a crushing device, a lateral moving device and an auxiliary support frame 4, the crushing device includes an annular support seat 21 and a hydraulic breaker 22, and the hydraulic breaker 22 is an existing mature technology product, commonly used for Installed on the front end of the excavator or loader to break some stone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com