Plate and diaphragm gripping device and method thereof

A grasping device and plate film technology, which is applied in the field of PCB manufacturing, can solve the problems of inaccurate positioning and easy generation of waste products, excessive alarm interruptions, and reduced production efficiency, and achieve a simple and practical method, reduced labor costs, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

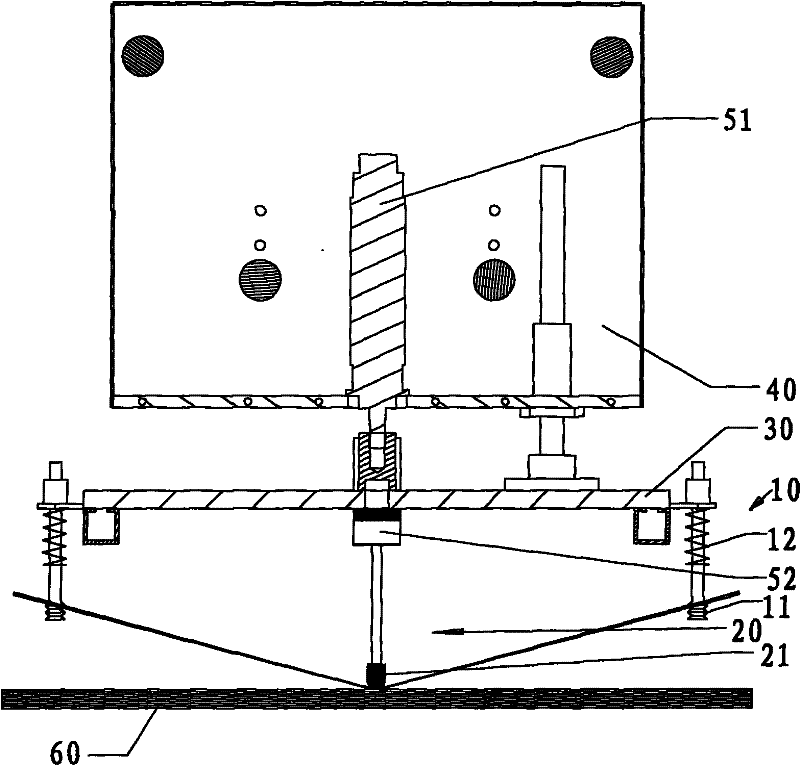

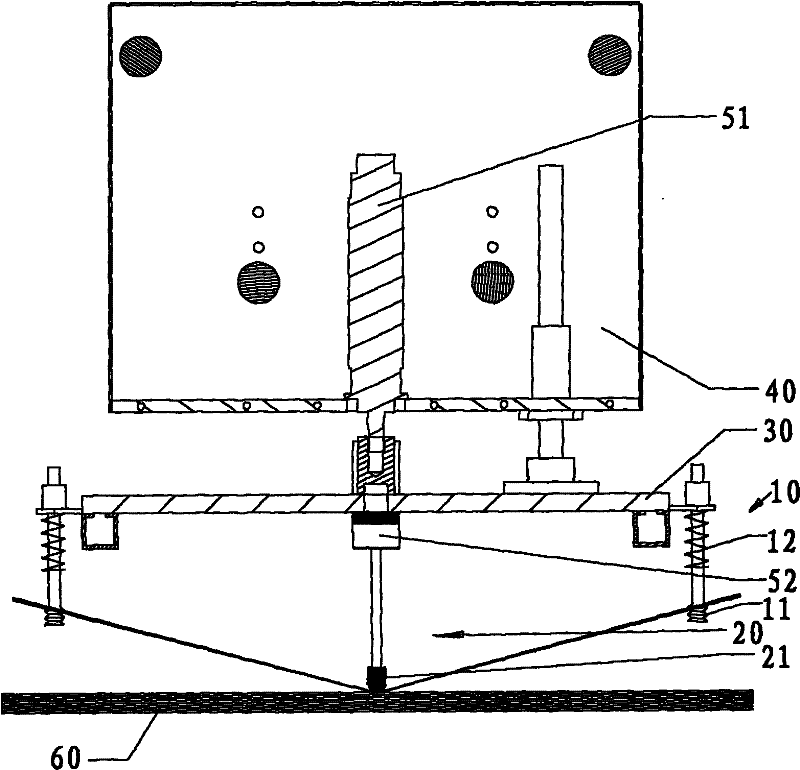

[0028] refer to figure 1 , the embodiments of the plate film grabbing device of the present invention include:

[0029] at least two gripping units 10;

[0030] at least one pressing unit 20 located between the two grabbing units 10;

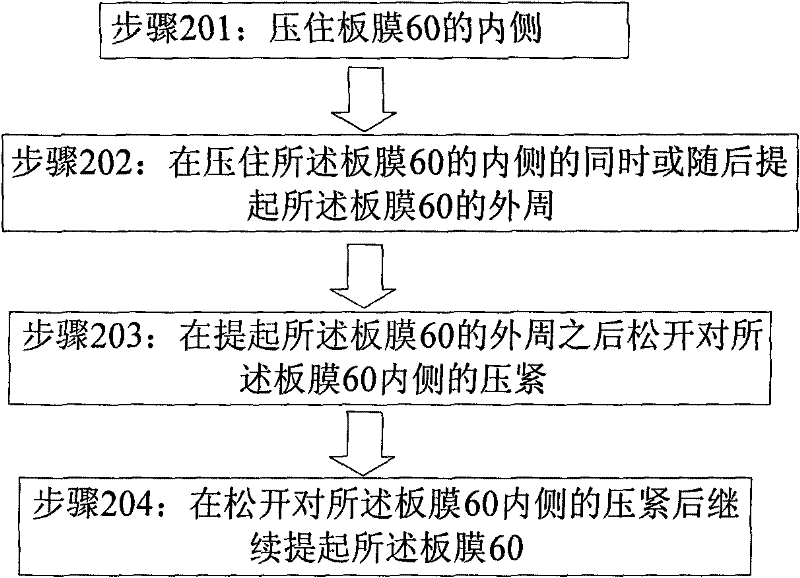

[0031] Drive the driving unit (not marked) of the grasping unit 10 and the pressing unit 20. When grabbing the plate film 60, the driving unit is used to drive the pressing unit 20 to press the inner side of the plate film 60, and drive the plate film 60. The grasping unit 10 grasps the outer periphery of the plate film 60 and lifts the outer periphery of the plate film 60 before the pressing unit 20 , and then drives the pressing unit 20 to loosen the plate film 60 .

[0032] The present invention designs a pressing unit 20 to press the inner side of the plate film 60 to be grasped, and then the grasping unit 10 grabs the outer periphery of the plate film 60 and lifts the outer periphery of the plate film 60 before the pressing unit 20 , so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com