Lens module

A lens module and lens holder technology, applied in the field of optical systems, can solve the problems of instability, uneven torque/torque, difficulty in accurately adjusting the relative position of the lens barrel and the lens holder, etc., to achieve accurate focusing, uniform locking force, To achieve the effect of focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

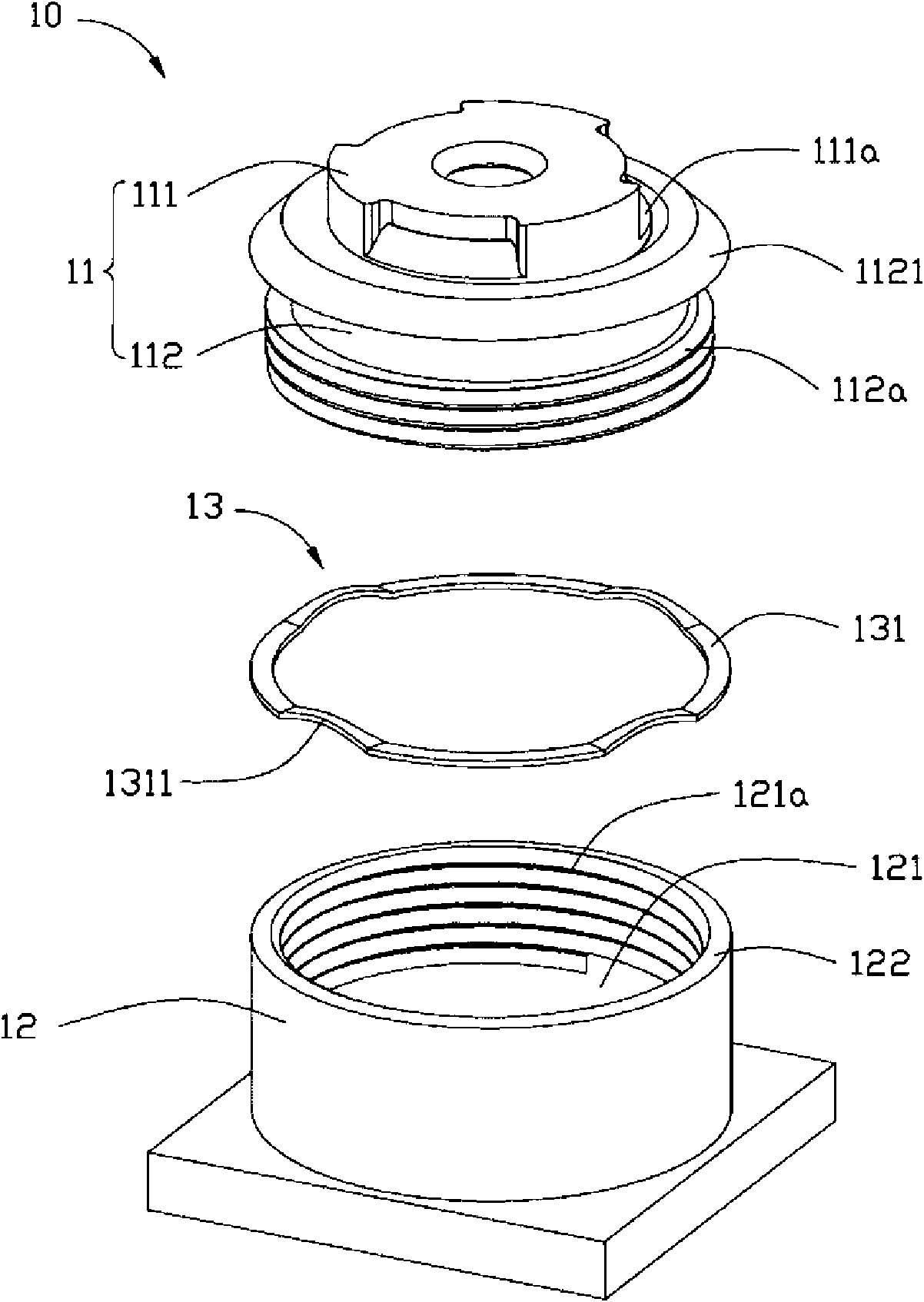

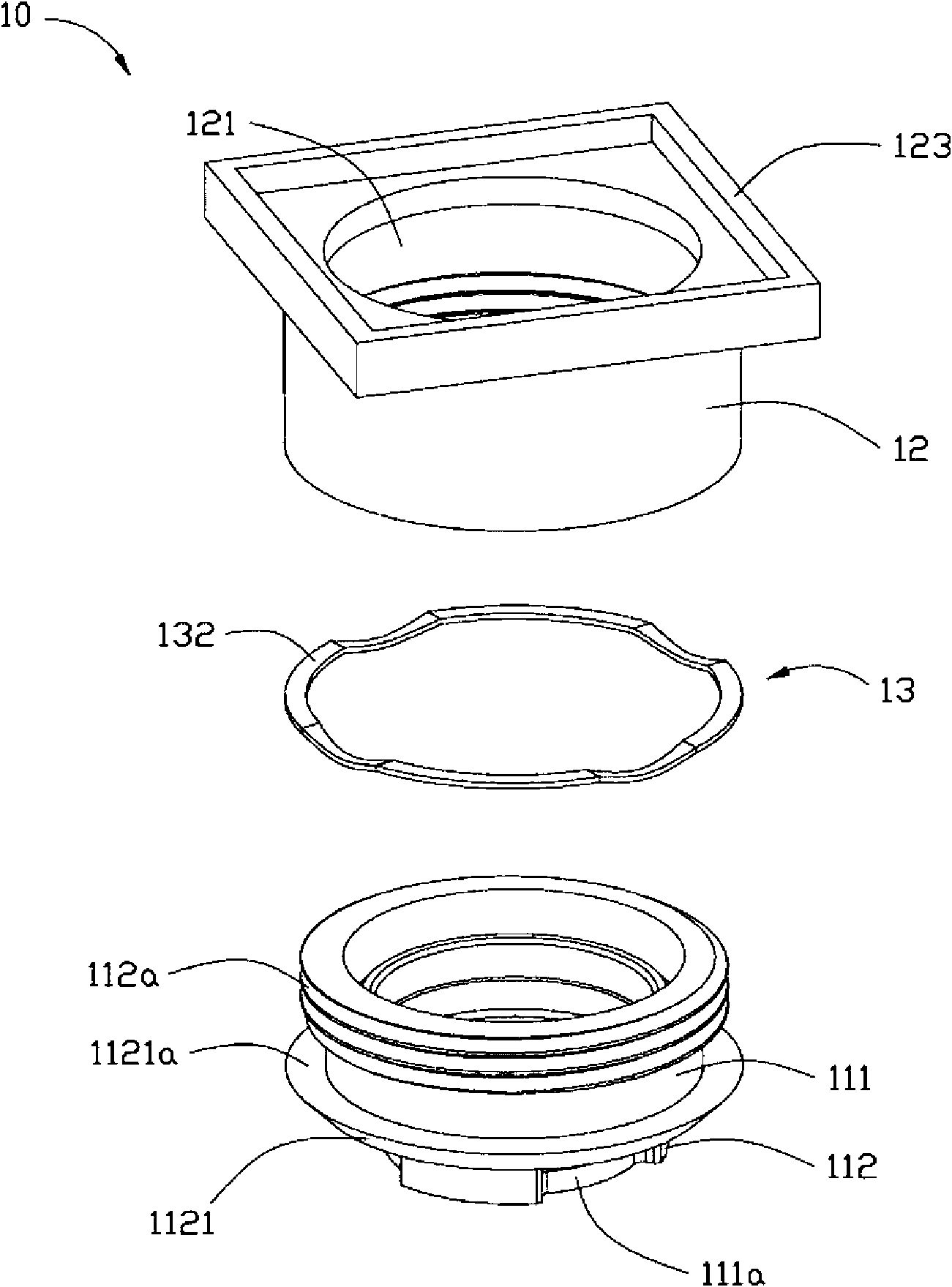

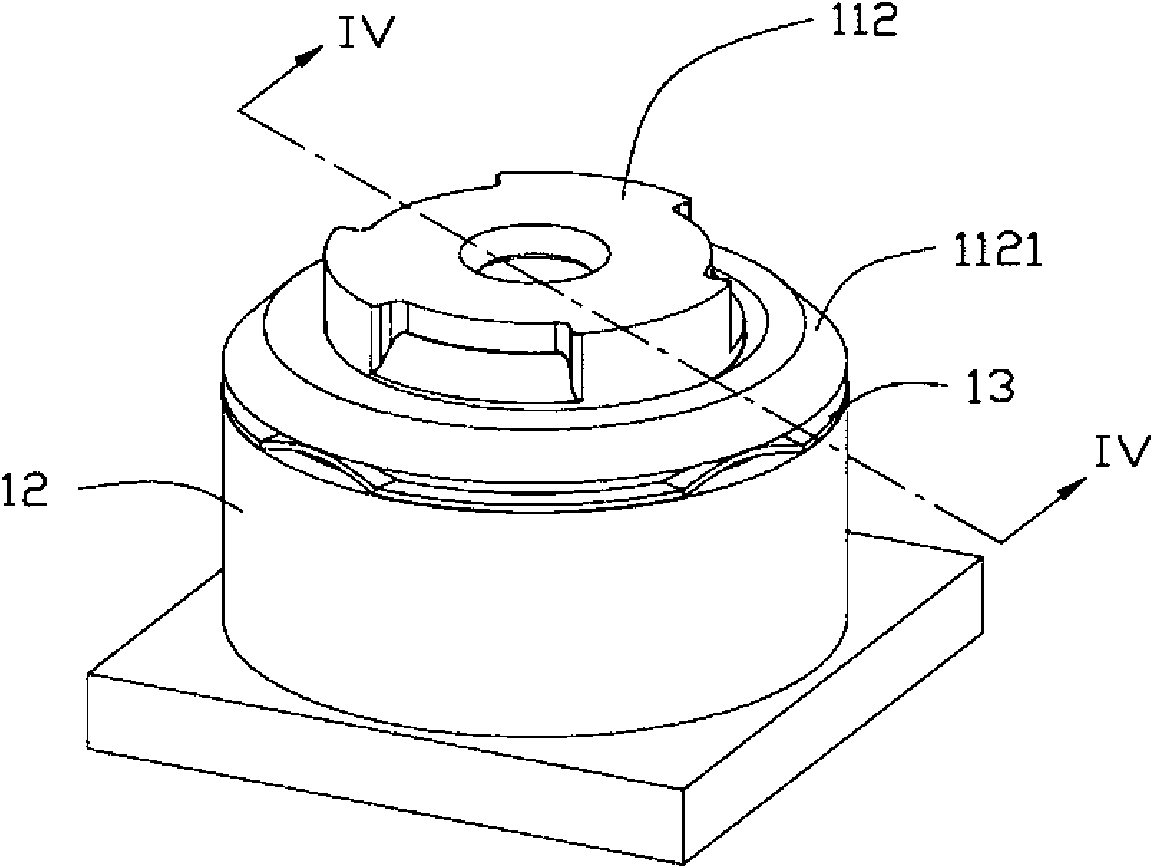

[0013] Such as Figure 1 to Figure 4 As shown, a lens module 10 provided by a preferred embodiment of the present invention includes a lens barrel 11 , a lens mount 12 and an elastic element 13 .

[0014] The inside of the lens barrel 11 accommodates elements such as a lens group, a spacer ring, and a filter (not shown in the figure). The lens barrel 11 sequentially includes an actuating part 111 and a connecting part 112 from the object side to the image side. A plurality of grooves 111 a are evenly spaced on the edge of the actuating part 111 , and the grooves 111 a are used to facilitate rotation of the actuating part 111 . The connecting portion 112 is cylindrical and coaxially connected with the actuating portion 111 . One end of the connecting portion 112 adjacent to the actuating portion 111 forms a crimping portion 1121 , and a crimping surface 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com