Leakage testing equipment for submersible pumps

A technology for sealing detection and submersible pumps, which is used in pump testing, mechanical equipment, and liquid tightness measurement using liquid/vacuum degree. Achieve the effect of good locking fastness and stability, simple locking action and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

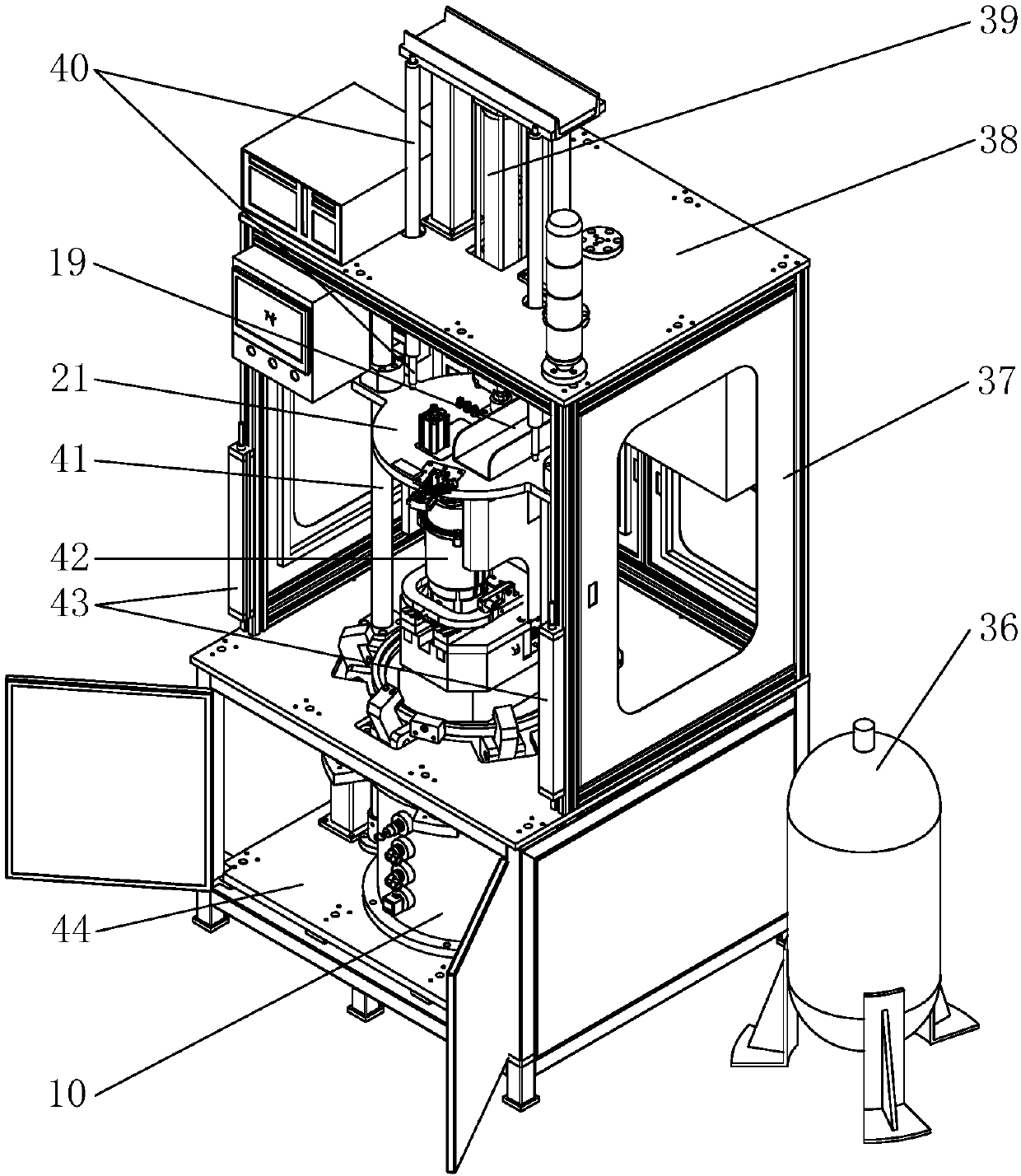

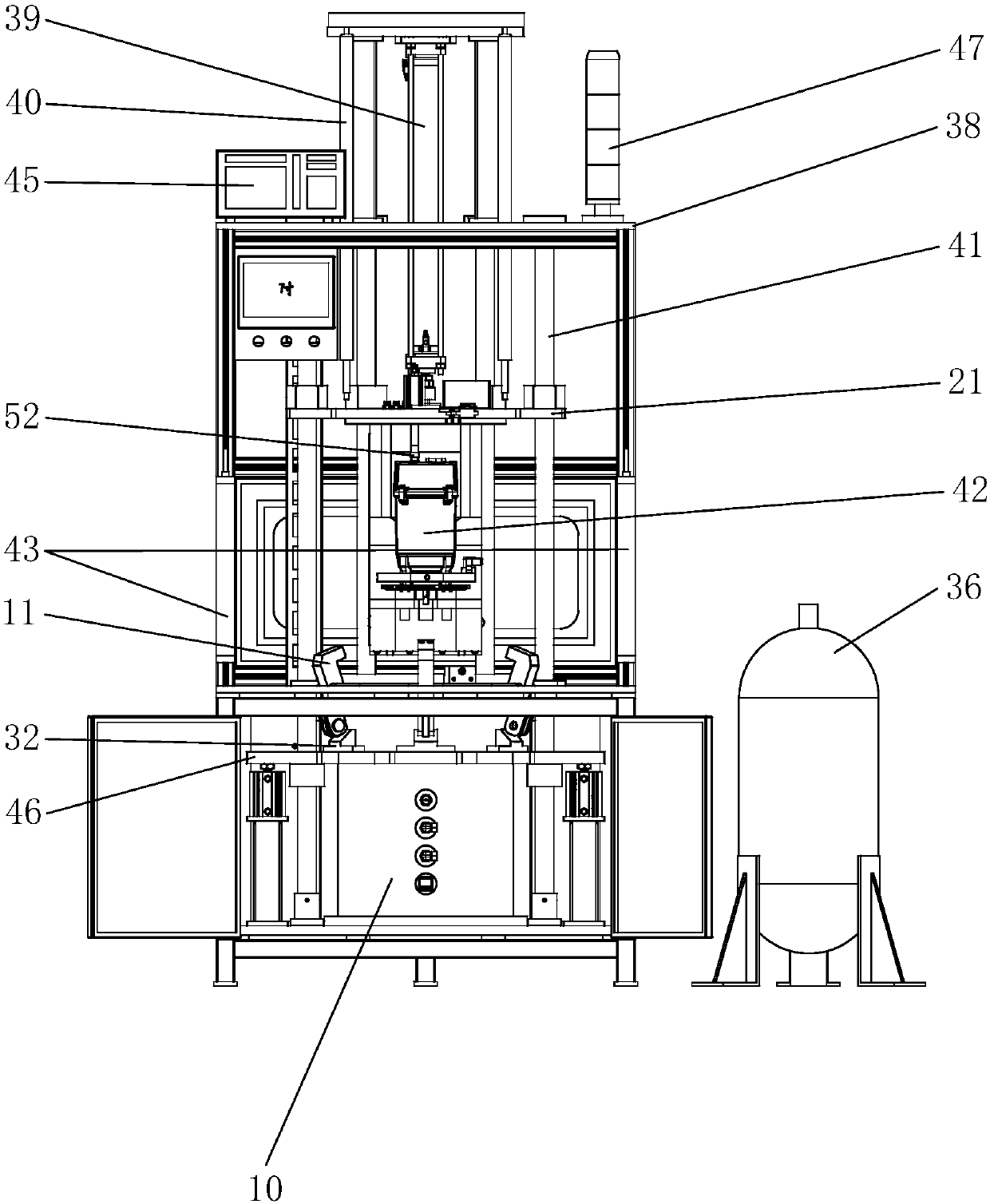

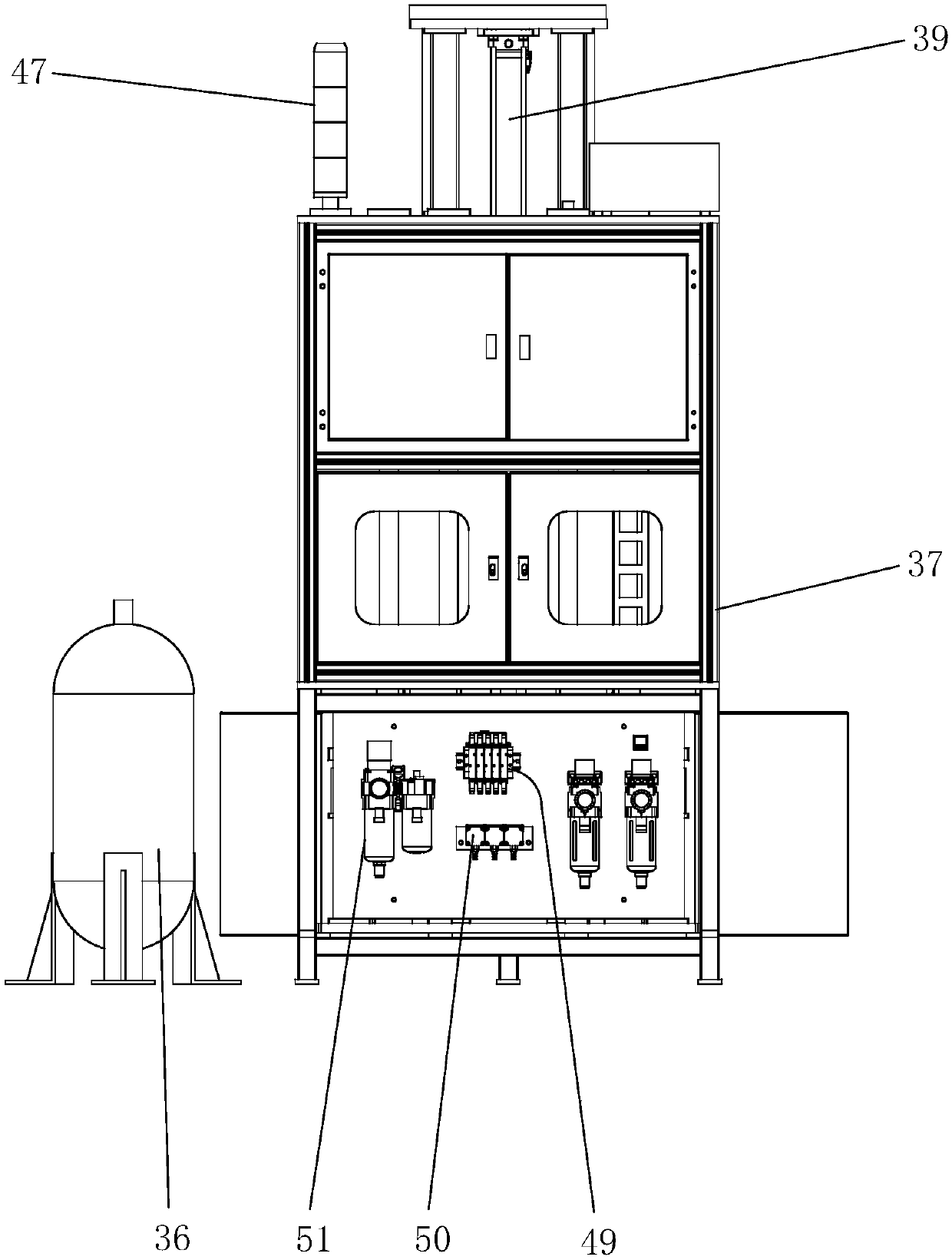

[0037] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 7 :

[0038] The leak detection equipment of the submersible pump, including the tank body 10 of the pressure tank fixed on the base 44 of the tank body 37 and the tank body 37, the base 44 outside the tank body 10 is evenly distributed with three or more vertical guide rods 41 in the circumferential direction , the top of the guide rod 41 is fixed on the top plate 38, and the tank cover 21 of the pressure tank is slid on the guide rod 41 between the top plate 38 and the tank body 10 and driven by the cylinder 39 fixed on the top plate 38. Lifting, the tank body 10 and the tank cover 21 are locked by an automatic locking device, and the lower side of the fixed vertical mounting plate 17 on the bottom surface of the tank cover 21 is provided with a supporting plate 28, a submersible pump positioning fixture and a cylinder drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com