Fixing device

A technology of fixing film and reflector, which is applied in electrography, optics, instruments, etc., can solve problems such as unfavorable displacement of reflector, and achieve the effects of improving heating efficiency, reducing start-up time, and suppressing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

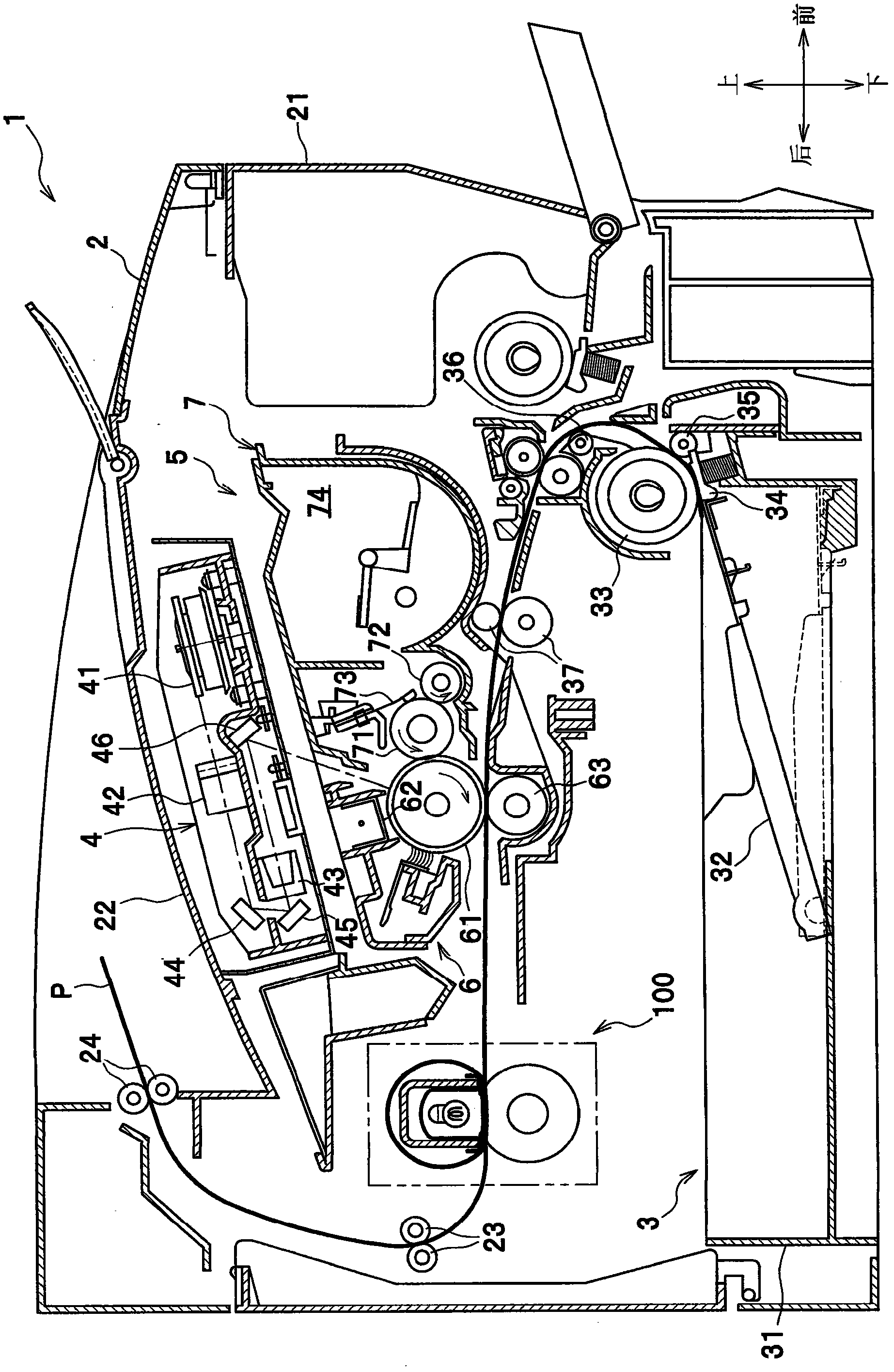

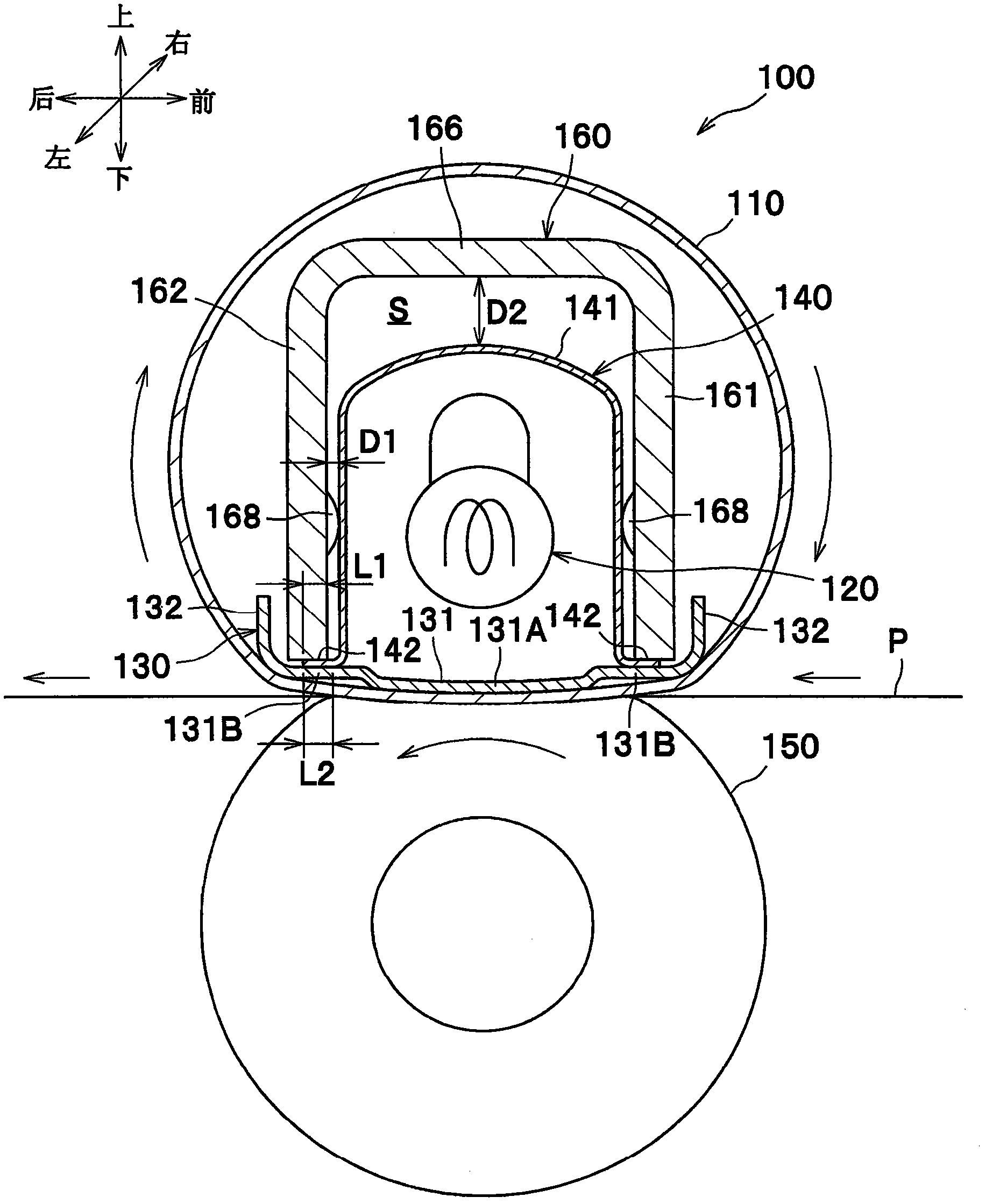

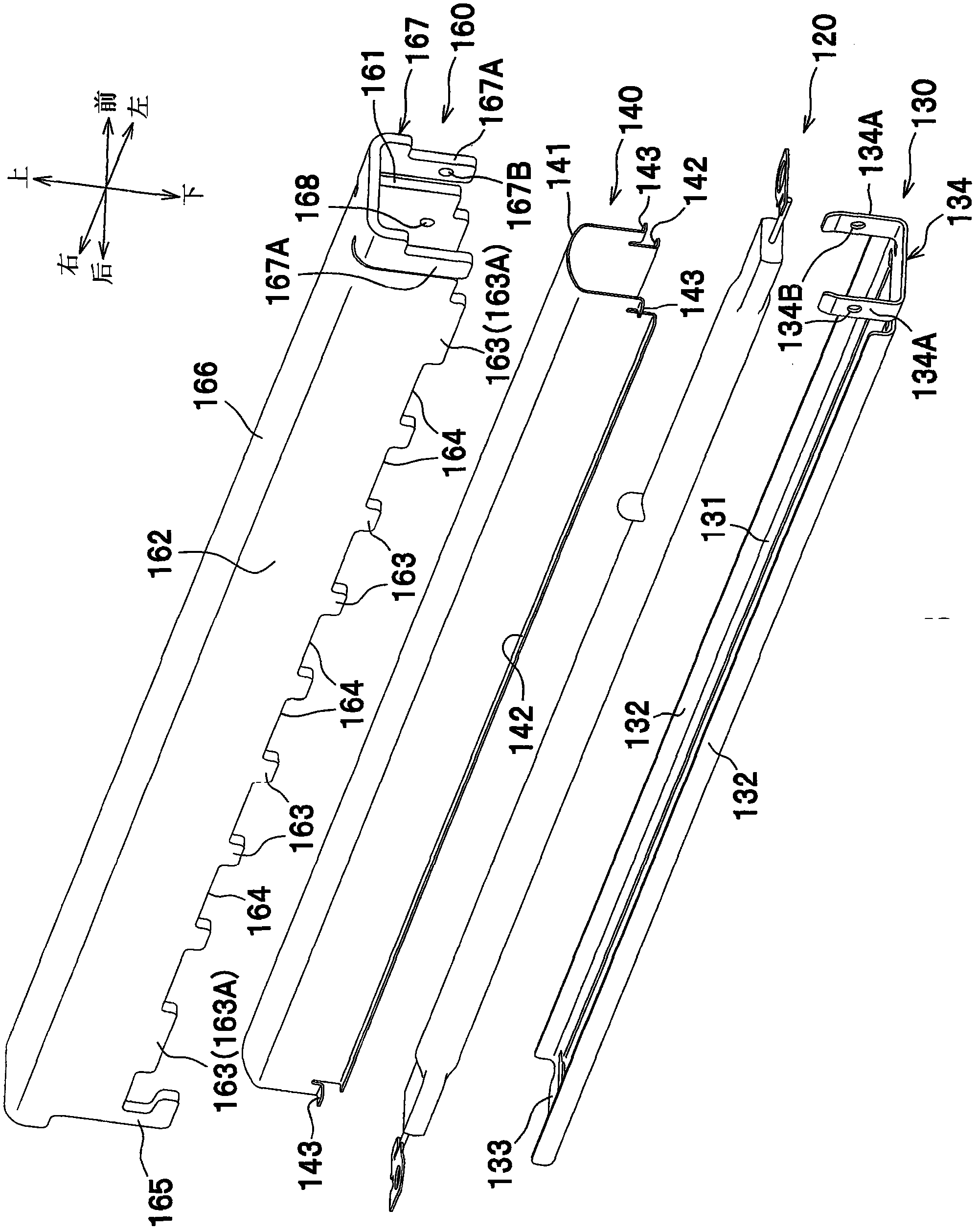

[0021] A detailed description will be given of exemplary embodiments of the present invention with reference to the accompanying drawings. In the following description, an overall arrangement of a laser printer 1 (image forming apparatus) provided with a fixing device 100 according to an embodiment of the present invention will be described, and then features of the fixing device 100 will be described in detail.

[0022]

[0023] as in figure 1 As shown in , a laser printer 1 includes a main body casing 2 and several members accommodated in the main body casing 2, the several members mainly including a sheet for feeding a sheet P (for example, of paper) as an example of a recording sheet. A material feeder unit 3, an exposure device 4, a process cartridge 5 for transferring a toner image (developer image) onto a sheet P, and a process cartridge 5 for thermally fixing the toner image transferred onto the sheet P The fixing device 100.

[0024] Hereinafter, in describing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com