Fire-fighting foam mixing ratio control method, system and fire-fighting truck provided therewith

A technology of mixing ratio and control system, which is applied in various fluid ratio control, fire rescue, etc., can solve problems such as poor applicability and system failure, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention optimizes the design of the control strategy based on the existing fire-fighting foam mixing ratio control technology, and its core is to provide a fire-fighting foam mixing ratio control method, which can increase the application range of the foam liquid and water mixing ratio, so that the fire truck can be used Any type of foam solution.

[0032] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

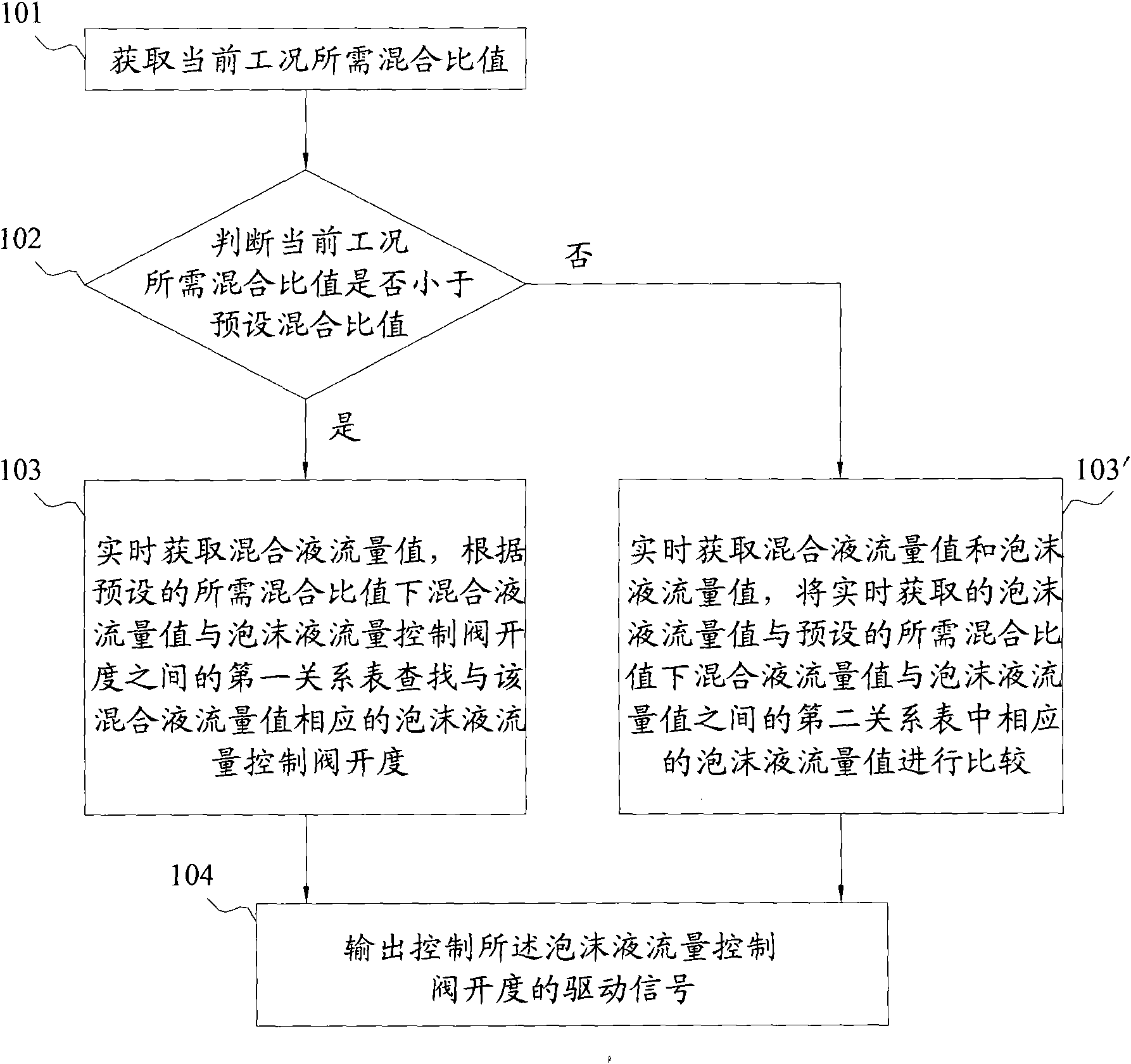

[0033] See figure 1 , which is a block diagram of the fire-fighting foam mixing ratio control method in this embodiment.

[0034] This method is used for controlling the mixing ratio of foam liquid and water, and carries out according to the following steps:

[0035] 101. Obtain the mixing ratio required by the current working condition; the mixing ratio described in this article is the ratio of foam liquid to water in the mixed liquid, and the range of the ratio is specifically 3‰~10%.

[0036] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com