Wire connecting method for duplex wave winding B voltage equalizing wires

A dual-wave winding and voltage-equalizing line technology, applied to the shape/style/structure of winding conductors, DC commutators, electrical components, etc. Problems such as the improvement of operation and design capacity, to achieve the effect of saving copper materials and easy assembly of embedded wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention provides a kind of connection method of double-wave winding type B voltage equalizing line, and its method is:

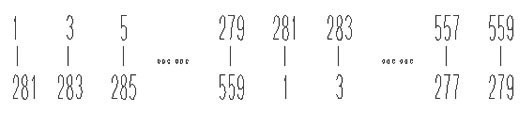

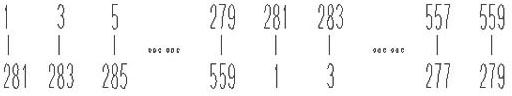

[0012] First, the two grooves every 180° on the circumference are divided into a group corresponding to the same equipotential point, such as figure 1 As shown, the grooves numbered 1 and 281 are one group, corresponding to the same equipotential point; the grooves numbered 3 and 283 are one group, corresponding to another equipotential point; and so on.

[0013] Secondly, each group of two equipotential points is connected by only one equalizing line. That is, the two equipotential points corresponding to the two slots numbered 1 and 281 need only be connected by one equalizing line, that is, the one equalizing line is only connected to 1-281, but does not need to be connected to 281-1.

[0014] In this way, compared with the prior art, the present invention only uses one equalizing line to connect the three equipotential points of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com