Lengthened head structure of main shaft of double-sided vehicle

A technology of lengthening the head and spindle, which is applied in the direction of metal processing equipment, etc., can solve the problems of high cost, low rigidity of the thin spindle box, and insufficient machining accuracy, and achieve the effects of good rigidity, quick and convenient installation and debugging, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

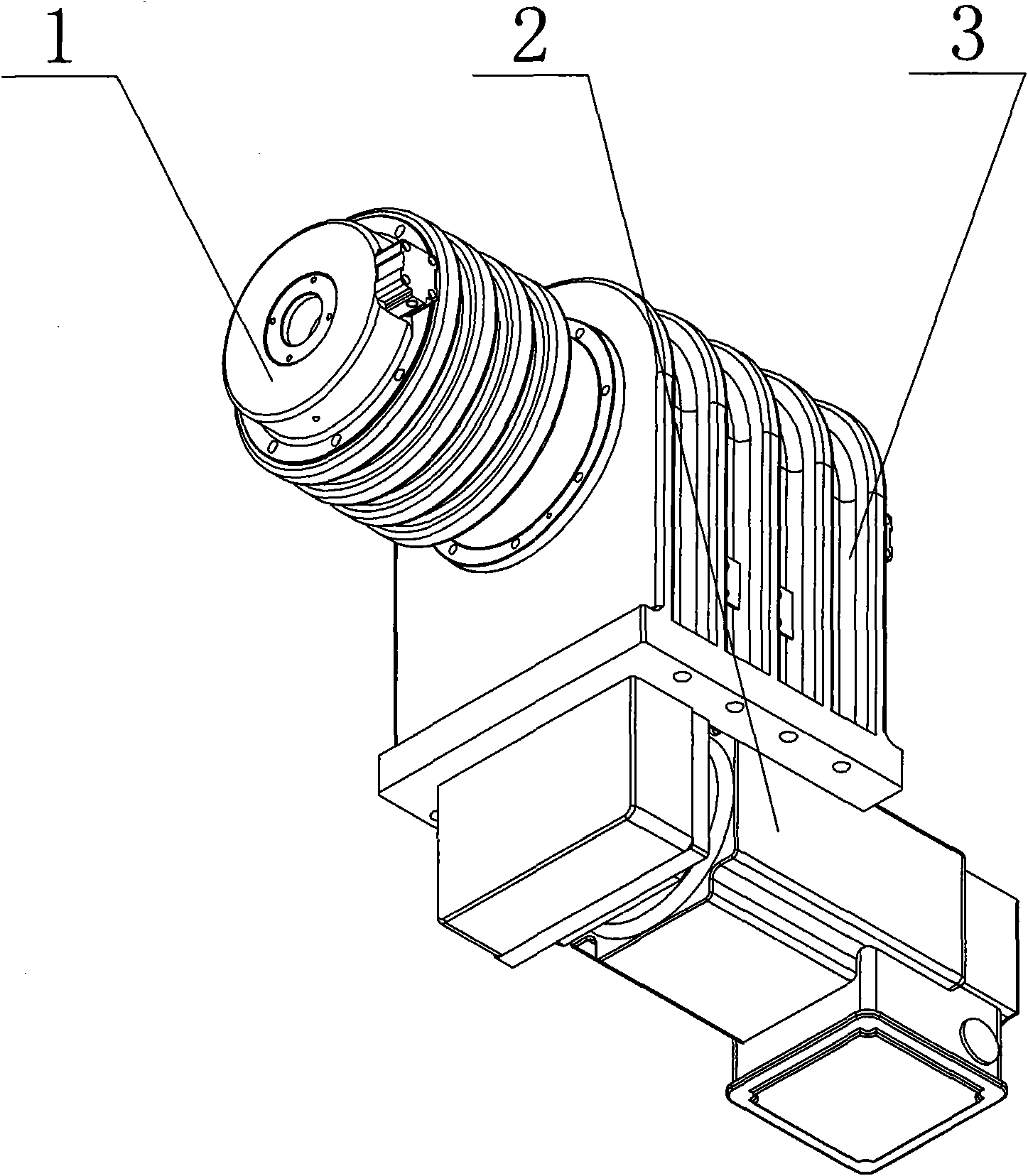

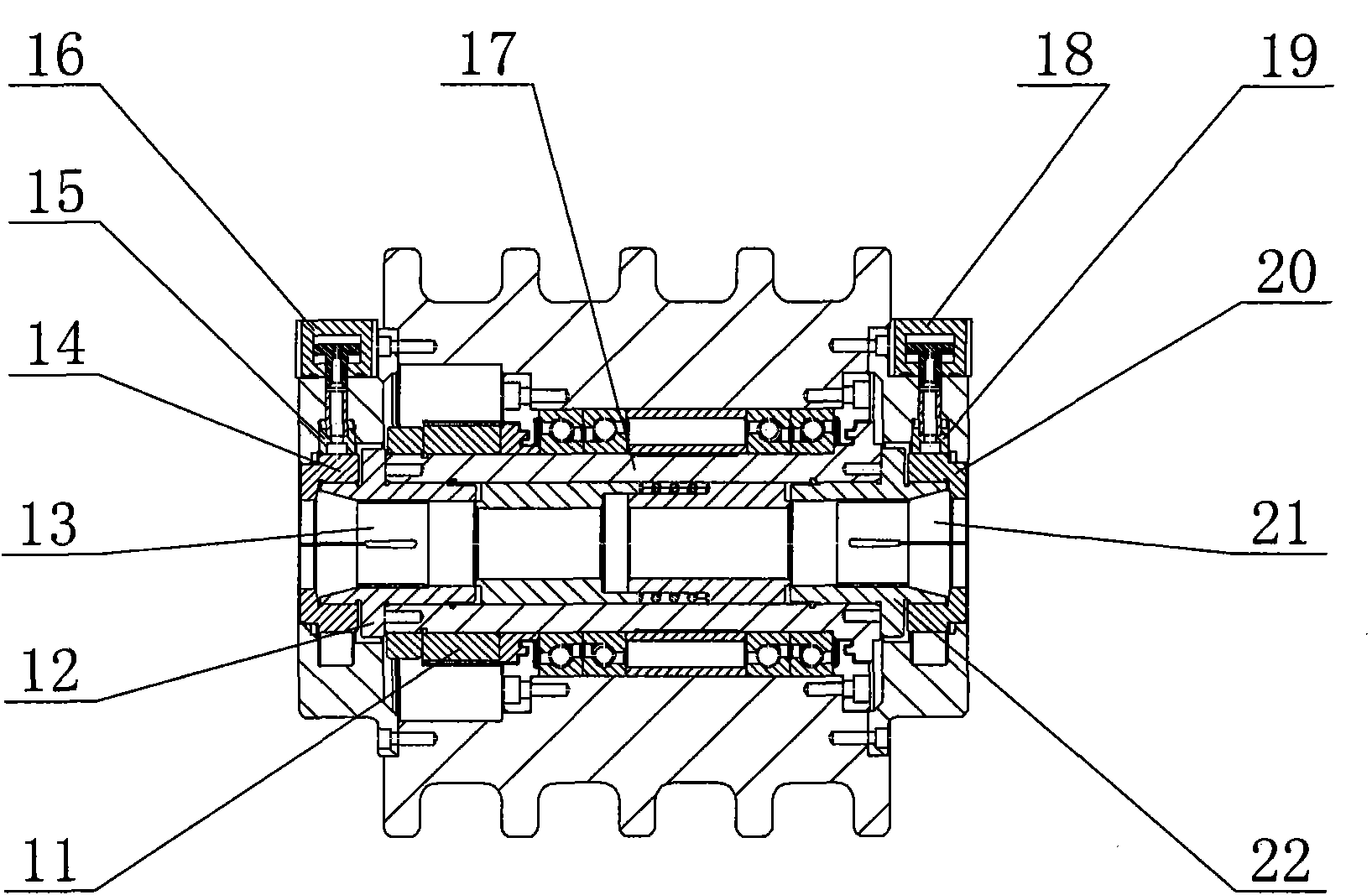

[0016] Example: such as figure 1 and image 3 As shown, the present invention relates to a double-sided turning spindle extension head structure applied to a CNC lathe for double-sided (end) processing, which includes a spindle box 3 and an extension head 1. When a double-sided processing lathe processes parts with different axis lengths , by connecting the spindle box 3 with the extension head 1 to process parts with a large axial length, and the extension head 1 with different axial lengths can be selected according to the axial length of the parts to be processed. After the accuracy of the spindle box 3 is calibrated, changing different extension heads 1 will not affect the accuracy of the headstock 3, and the clamping method of the parts to be processed will not change after the extension head 1 is added.

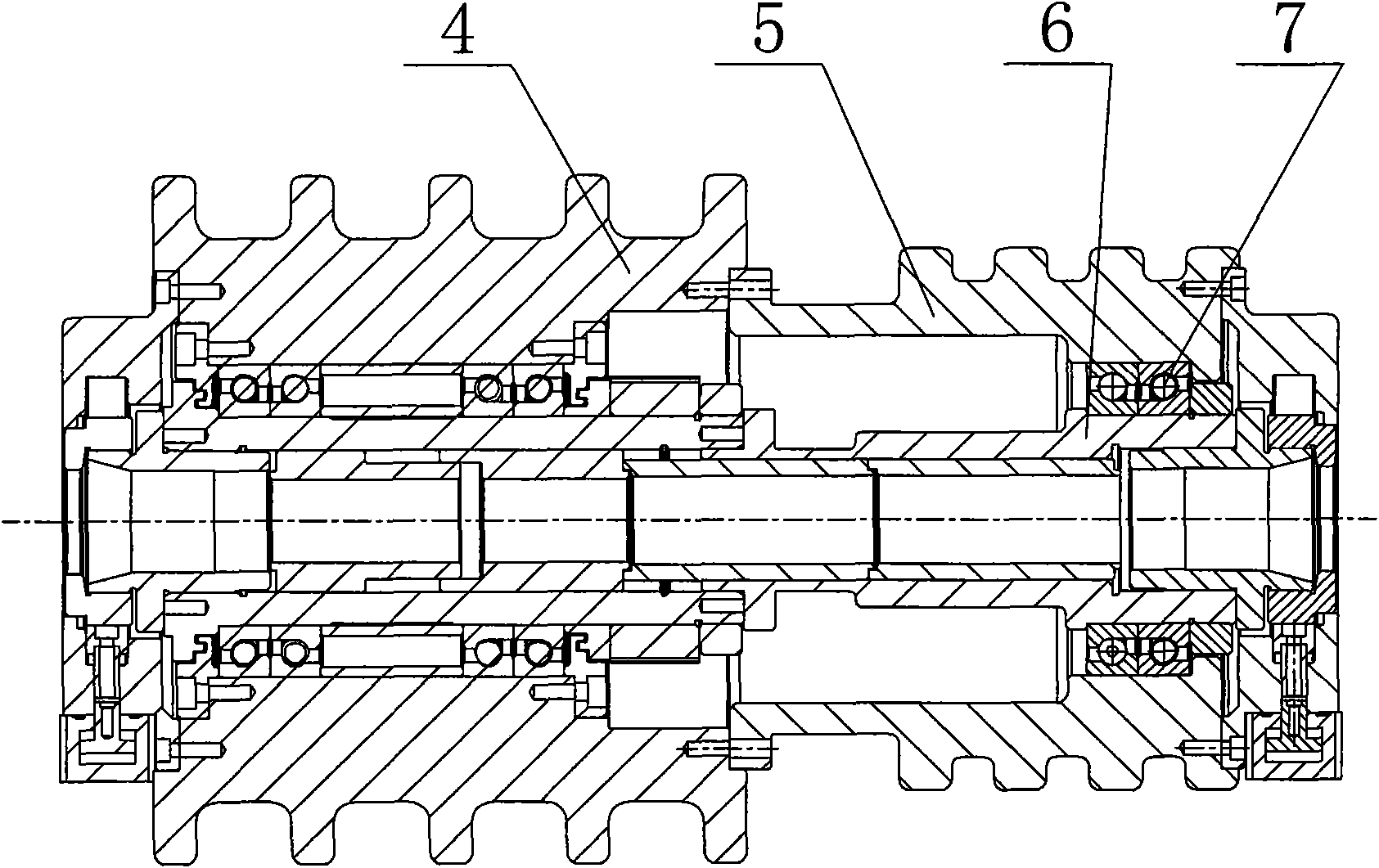

[0017] The extension head 1 is provided with an extension shaft 6 that matches the rotating main shaft 17 of the headstock 3, and the two ends of the extension head 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com