Grinding method

A technology for grinding and chemical machinery, which is applied in the direction of grinding devices, grinding machine tools, and parts of grinding machine tools. It can solve problems such as monitoring program failure and achieve the effect of avoiding monitoring failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

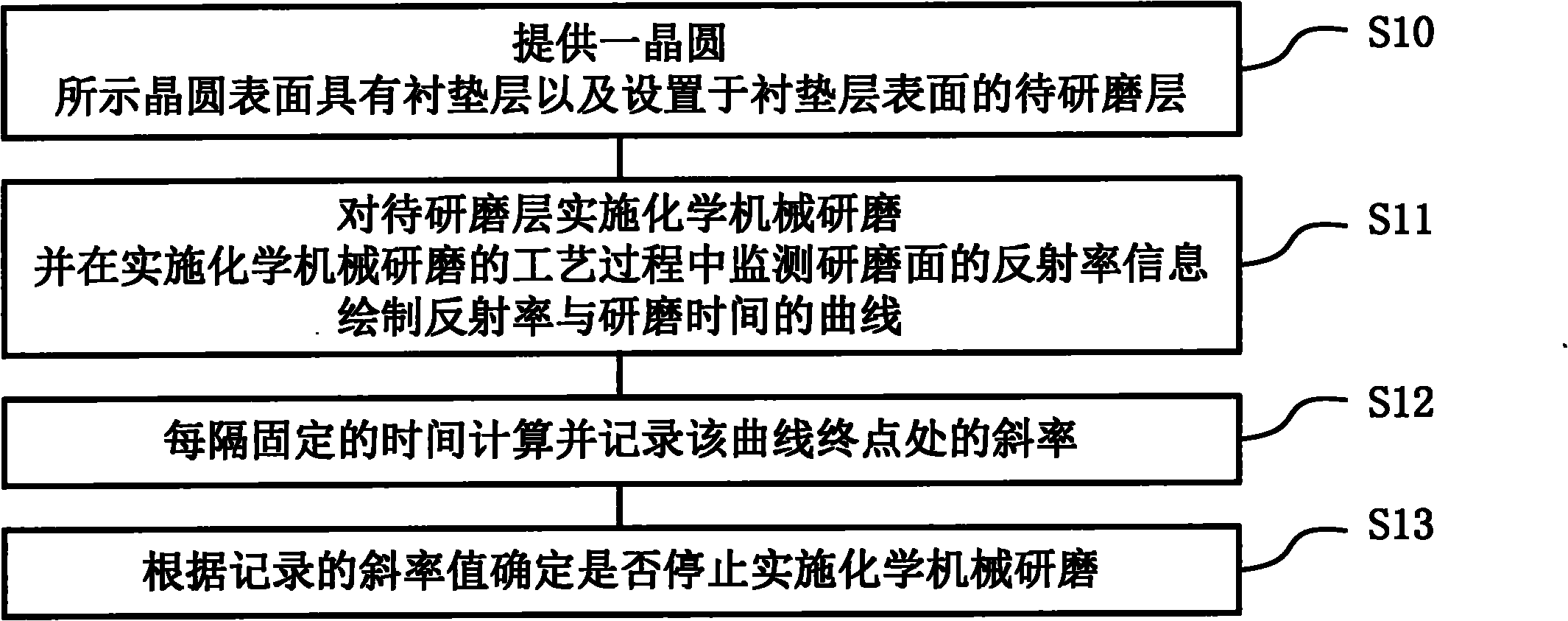

[0015] The specific implementation of the method for monitoring the interface during the grinding process provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0016] attached image 3 Shown is a schematic diagram of the implementation steps of this specific embodiment, including: step S10, providing a wafer, the surface of the wafer shown has a liner layer and a layer to be polished disposed on the surface of the liner layer; step S11, implementing Chemical mechanical grinding, and monitor the reflectivity information of the grinding surface during the process of implementing chemical mechanical grinding, and draw the curve of reflectivity and grinding time; step S12, calculate and record the slope at the end point of the curve at regular intervals; step S13. Determine whether to stop performing chemical mechanical polishing according to the recorded slope value.

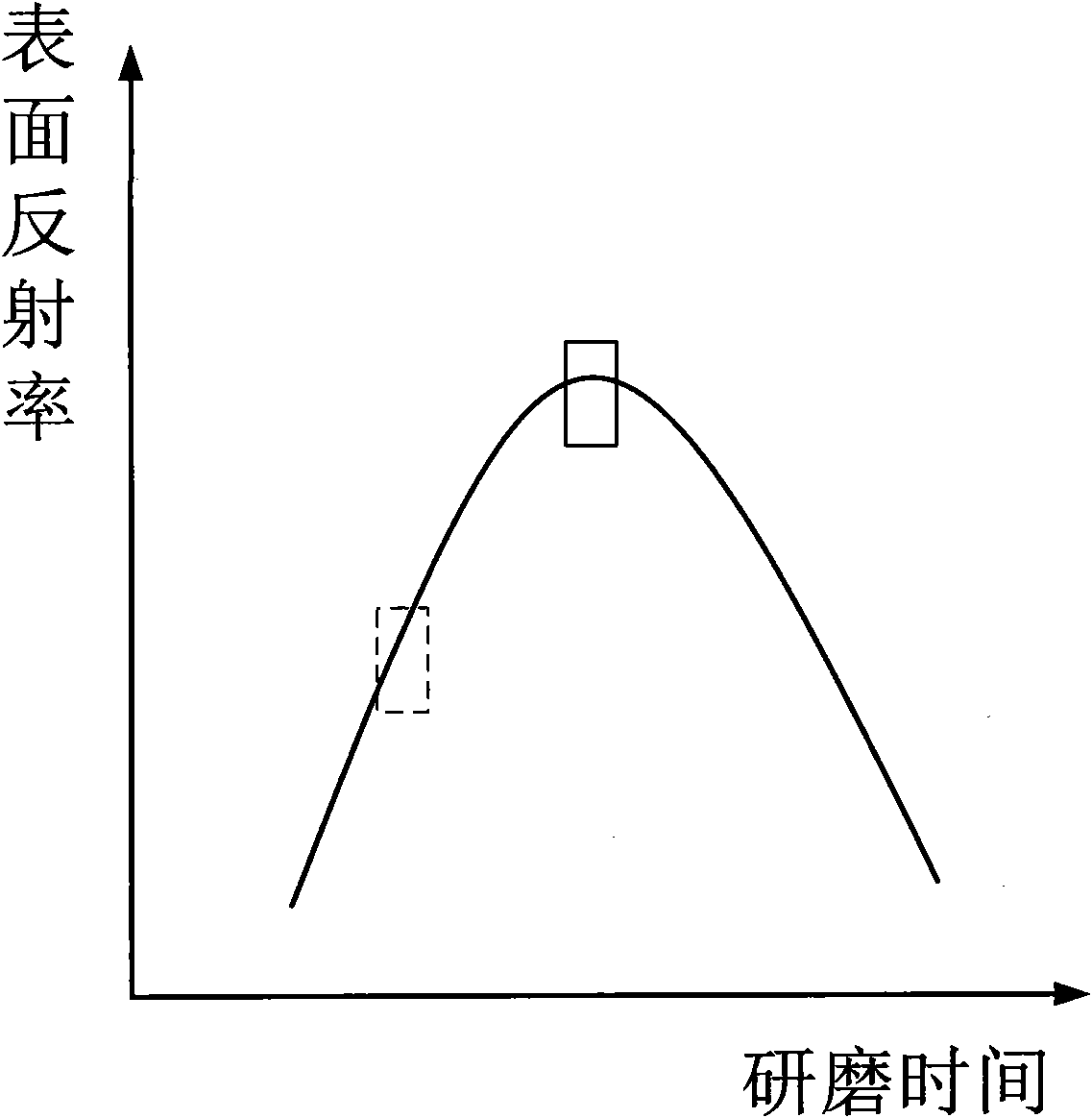

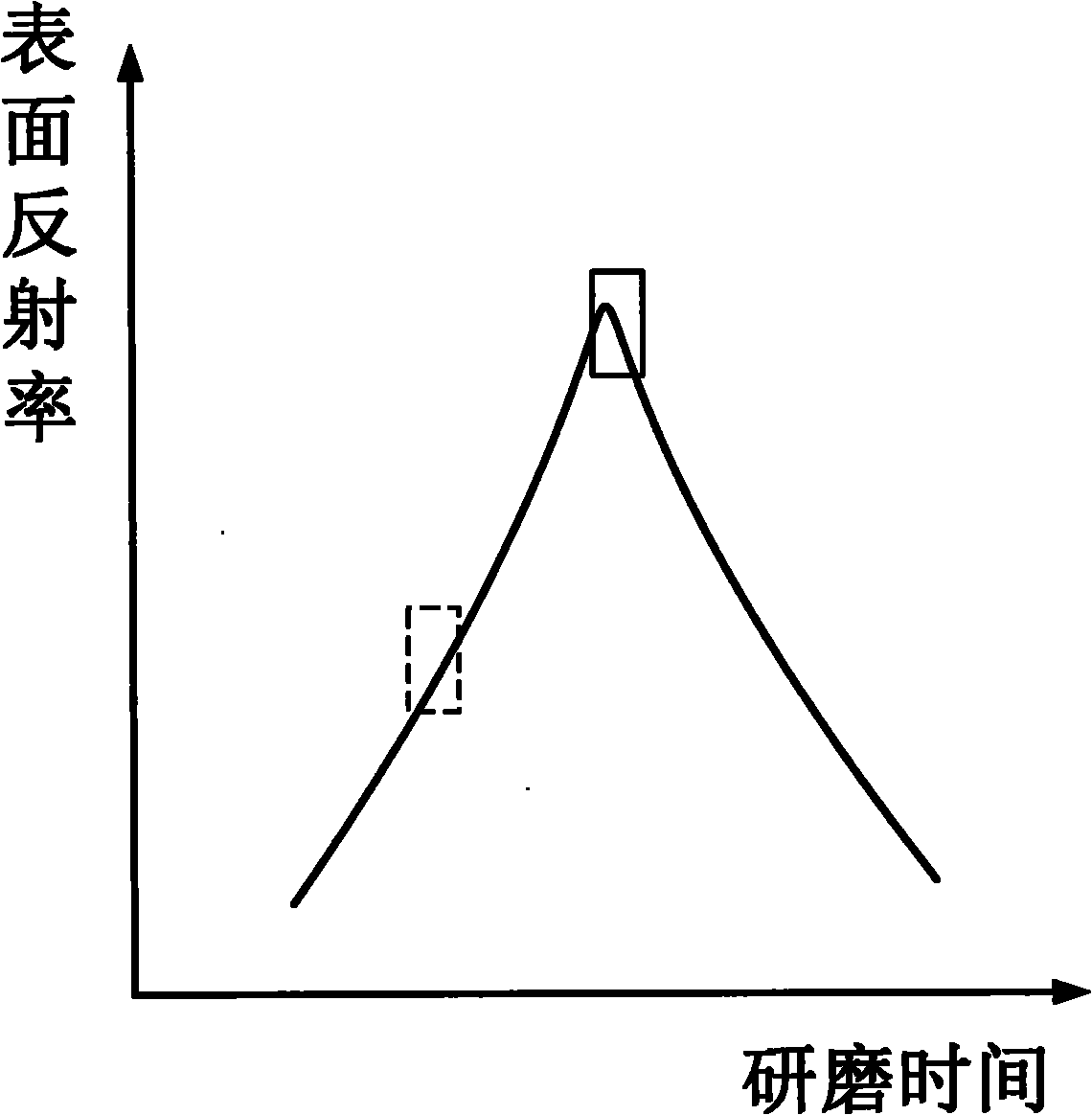

[0017] attached Figure 4 As shown, referring to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com