Tableware rotation type dish-washing method and household dishwasher using same

A rotary, dishwasher technology, applied in the direction of washing machine/washing machine for tableware, washing machine/rinsing machine parts for tableware, household cleaning device, etc. Water consumption and other issues to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

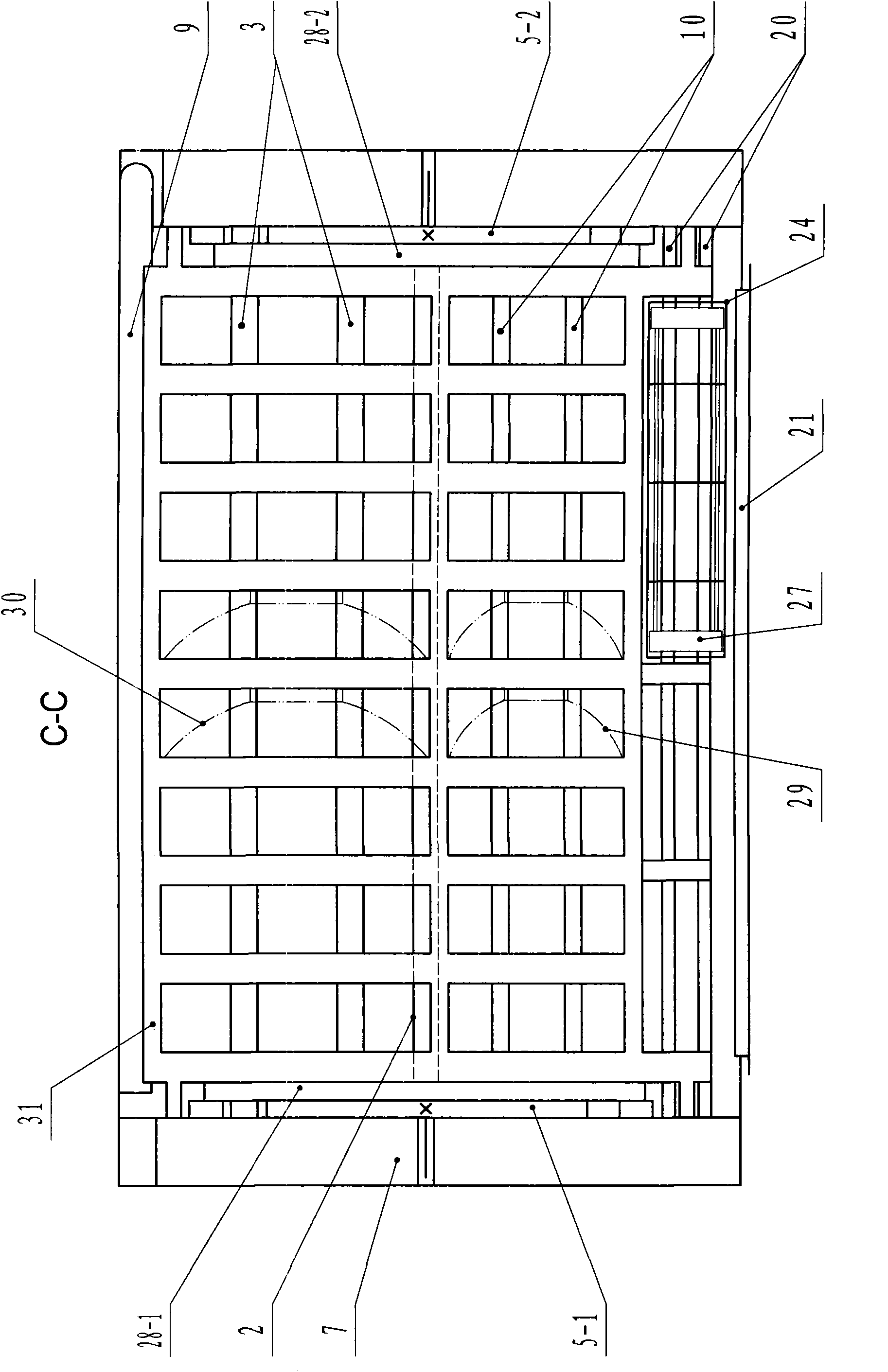

[0030] A rotary tableware washing method includes two aspects: tableware rotation and water jetting by a water spray mechanism to impact tableware. The idler is driven and rotated by the power mechanism, the tableware and the idler rotate oppositely, and the surface of the rotating tableware is sprayed by a jet of water.

[0031] The jet of water moves up and down to spray and wash the surface of the rotating tableware.

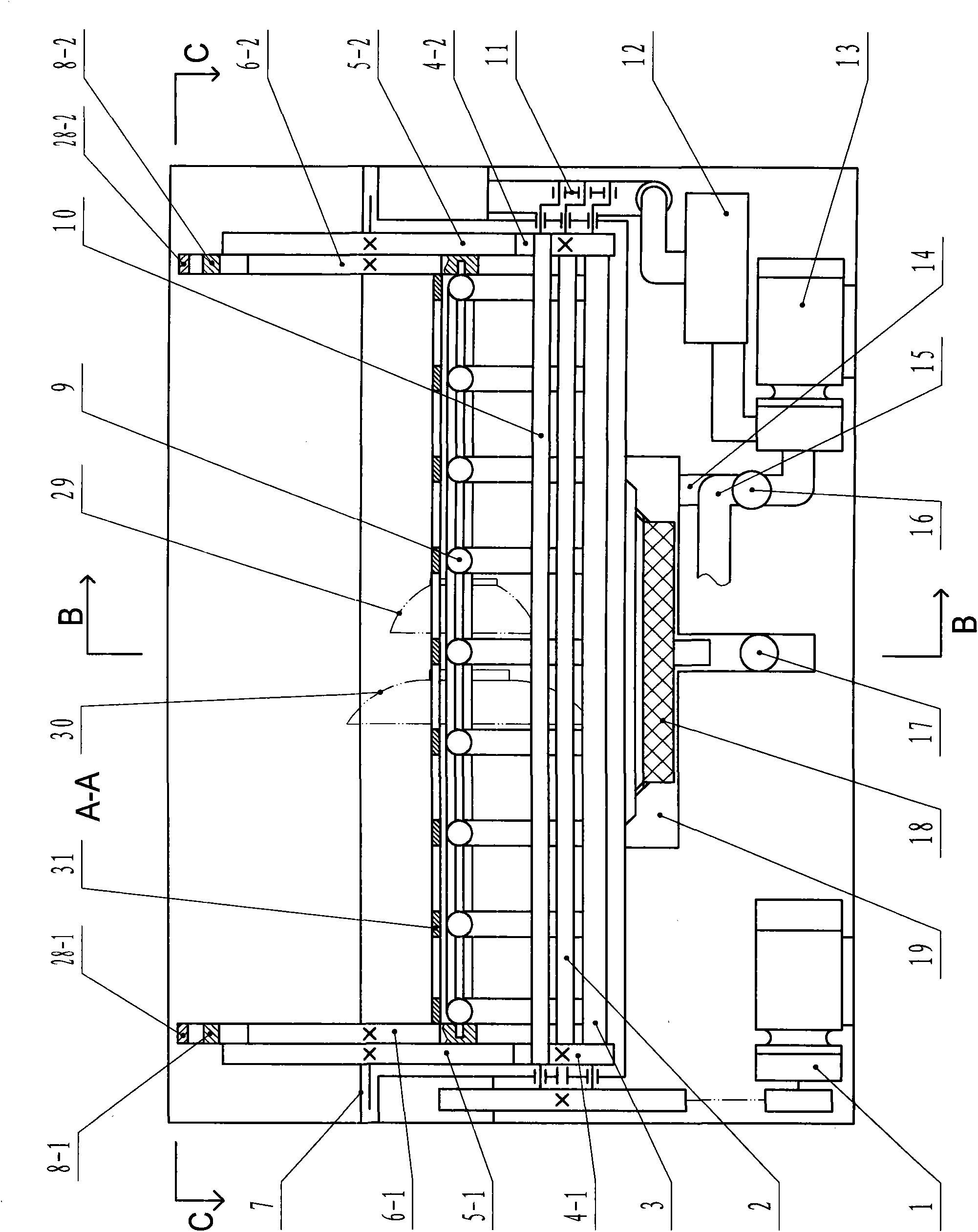

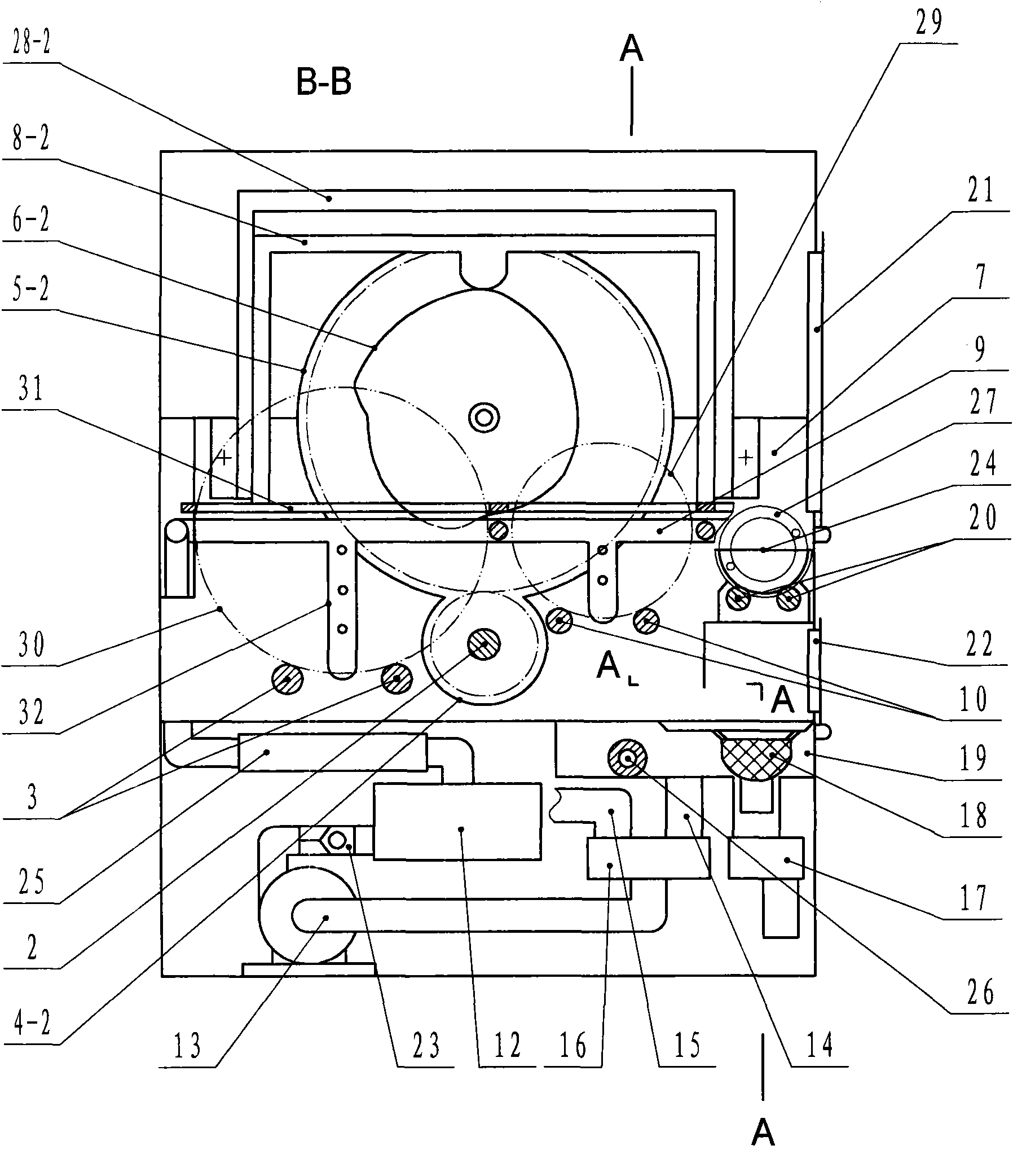

[0032] refer to Figure 1 to Figure 3 , a tableware rotary type household dishwasher using the above method, including a casing, a water pump 13, a dishwasher 7, a filter screen 18 and a power mechanism, the dishwasher is provided with multiple sets of horizontal rollers and water spray racks 9 , each group of rollers is connected with the power mechanism, the water spray frame 9 is arranged above each group of rollers, and the plurality of water spray pipes 32 in the water spray frame 9 are arranged vertically downward at intervals and are respectively loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com