Uninterrupted feeding auxiliary device of printing machine, and bearing plate and working principle thereof

A technology for auxiliary devices and printing presses, which is applied in thin material handling, transportation and packaging, and separation of objects, etc., can solve problems such as low work efficiency and loss of printing press production capacity, and achieve the effect of saving time and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

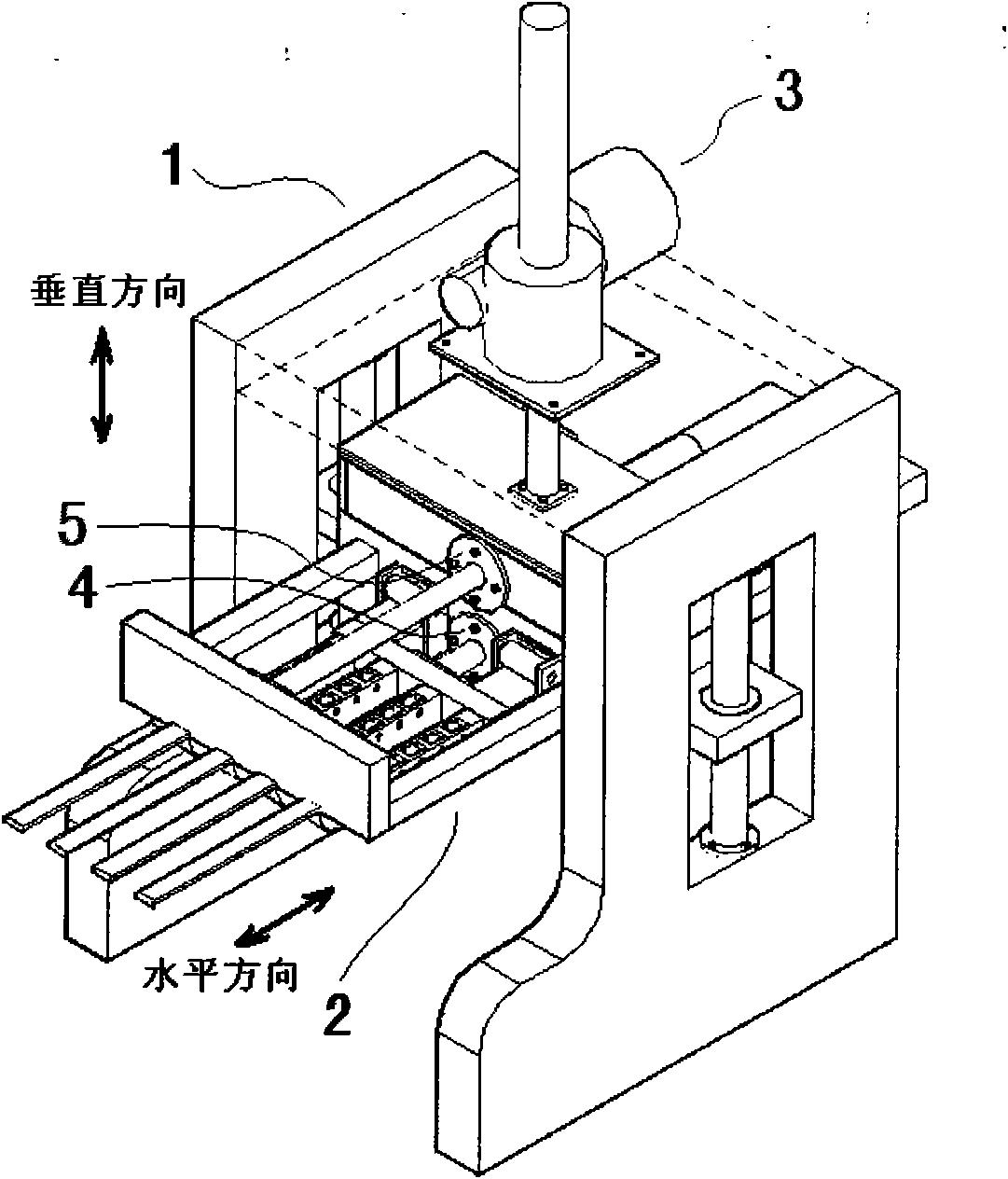

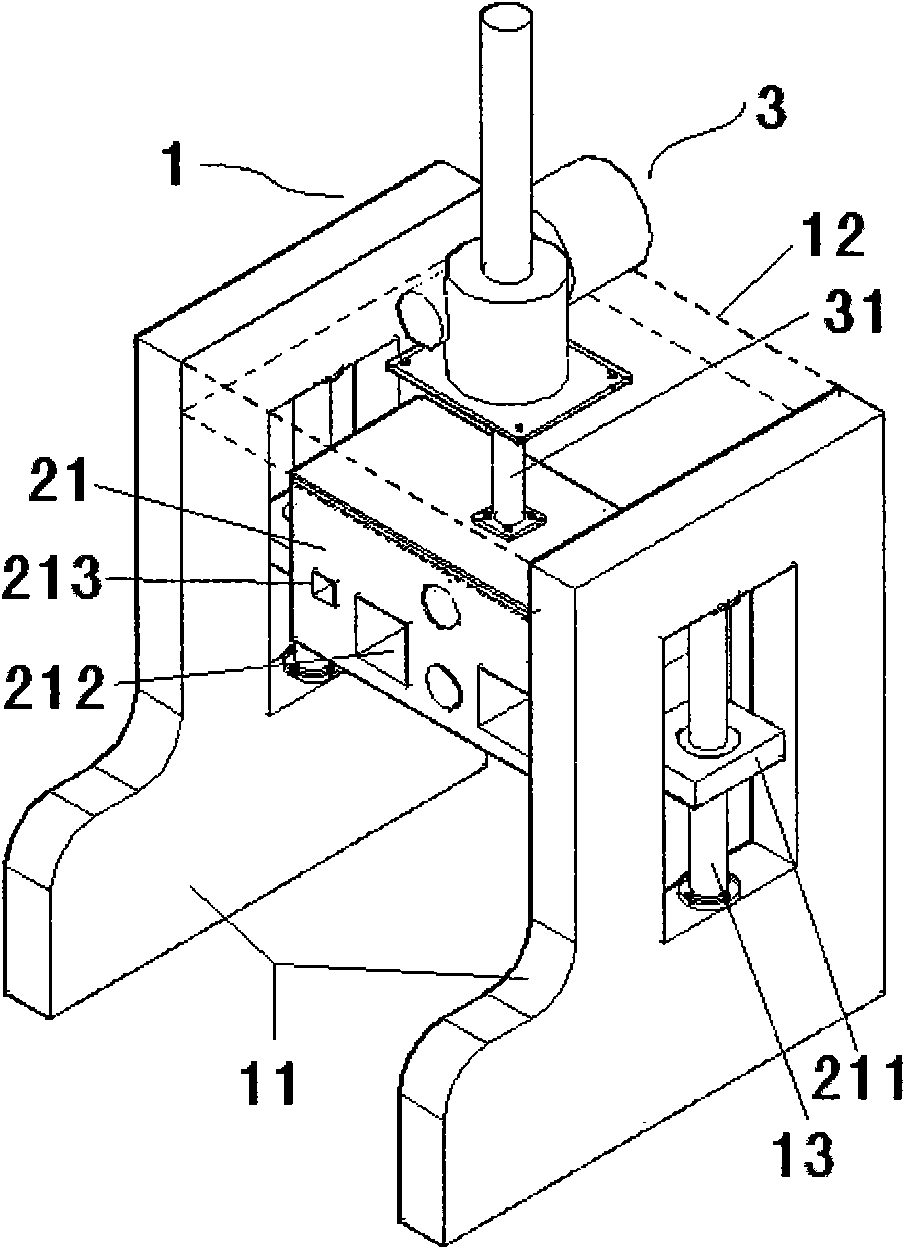

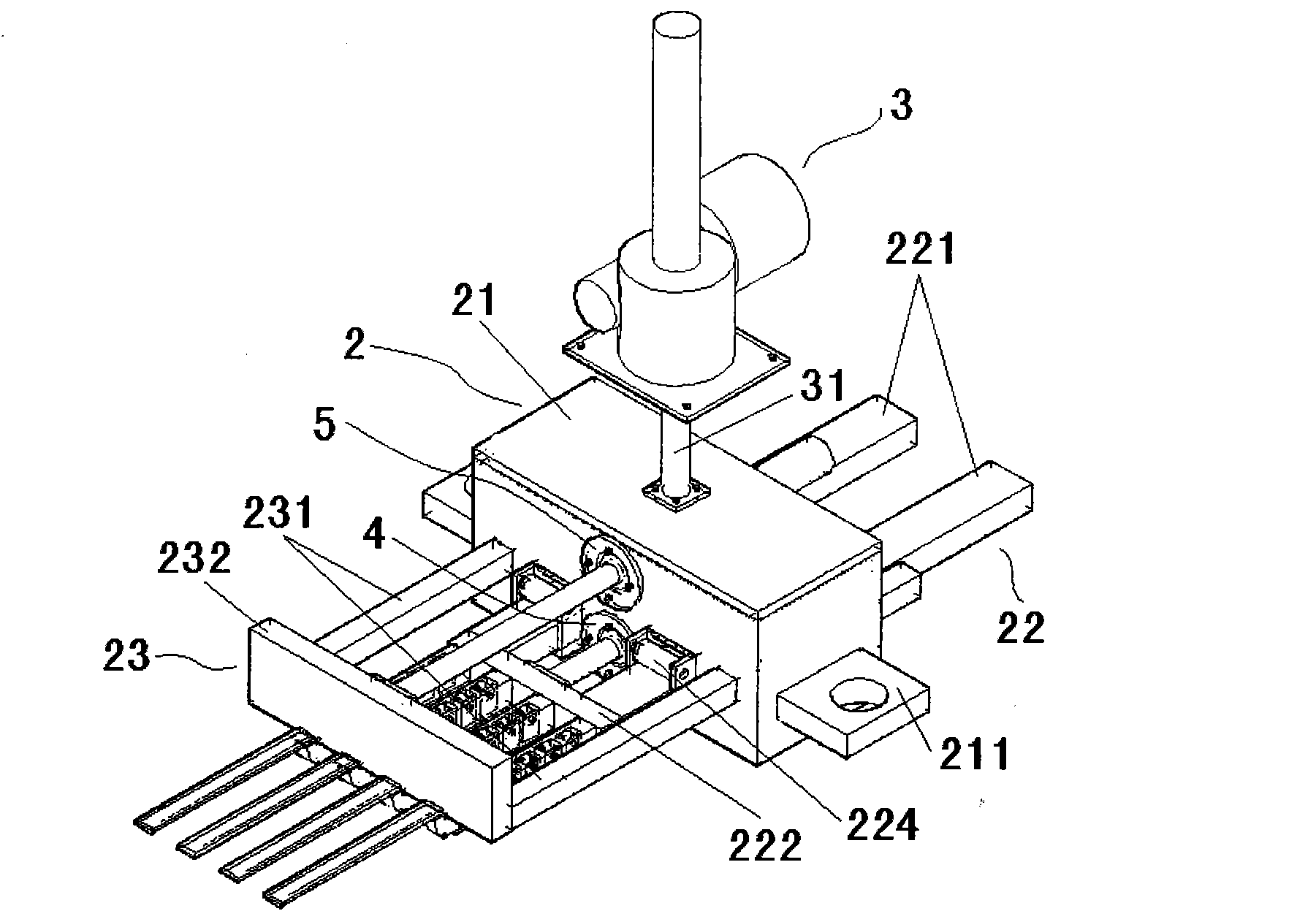

[0028] Such as figure 1 As shown, an auxiliary device for uninterrupted feeding of printing presses related to the present invention includes the following components: a machine base 1, a bracket mechanism 2, a bracket lifting drive device 3, a main bracket telescopic drive device 4, a secondary Bracket telescopic drive device 5; as figure 2 As shown, the base includes: two support bodies 11, a connecting plate 12 and at least one pair of guide posts 13; as figure 2 , image 3 As shown, the bracket mechanism includes: a bracket base 21, a main bracket 22, and a sub-bracket 23; both sides of the bracket base 21 have guide sleeve fixing structures 211, main and sub-bracket guide holes 212 / 213; if Figure 5 , Image 6 As shown, the main and auxiliary brackets are composed of respective guide rods 221 / 231, beams 222 / 232 and several supporting sheets 223 / 233. The thickness of the main supporting sheet 223 can ensure that at least one new printing plate 7 is stacked. objects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com