Strip threading method of strip steel in silicon steel continuous annealing drying furnace

A drying furnace and silicon steel technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of inconvenient threading, difficult operation, and affecting productivity, and achieve the effects of reducing the difficulty of threading, simple operation, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

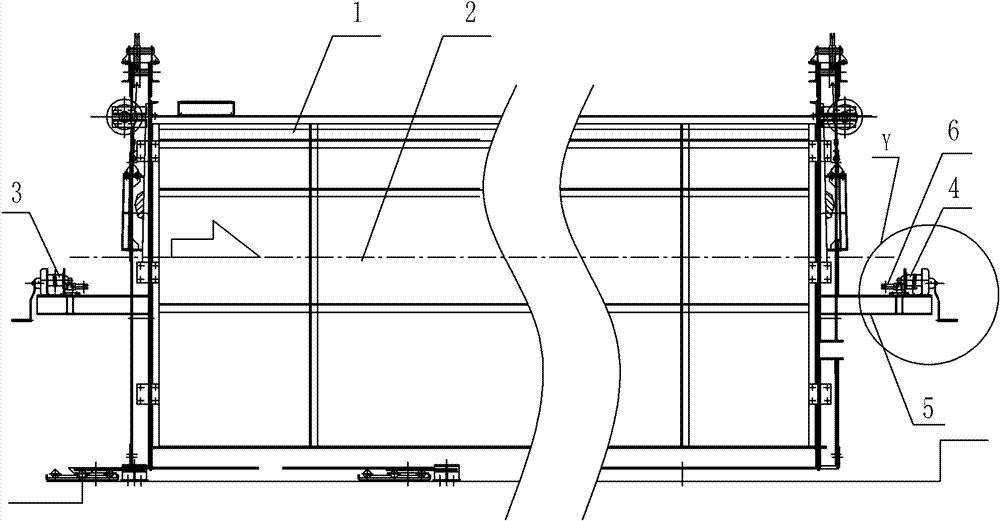

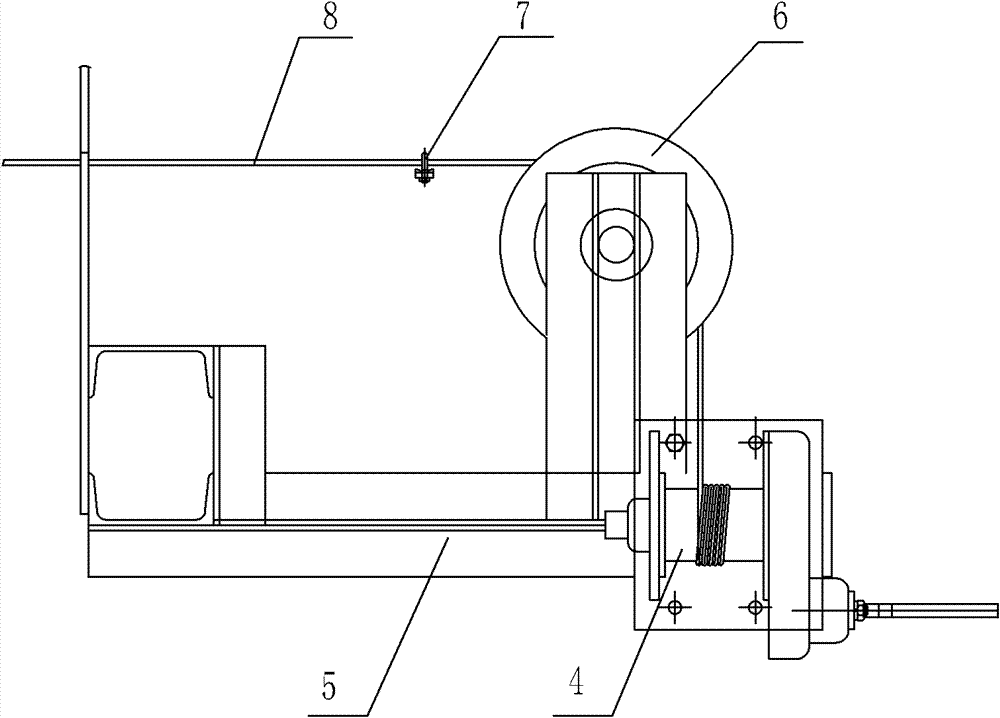

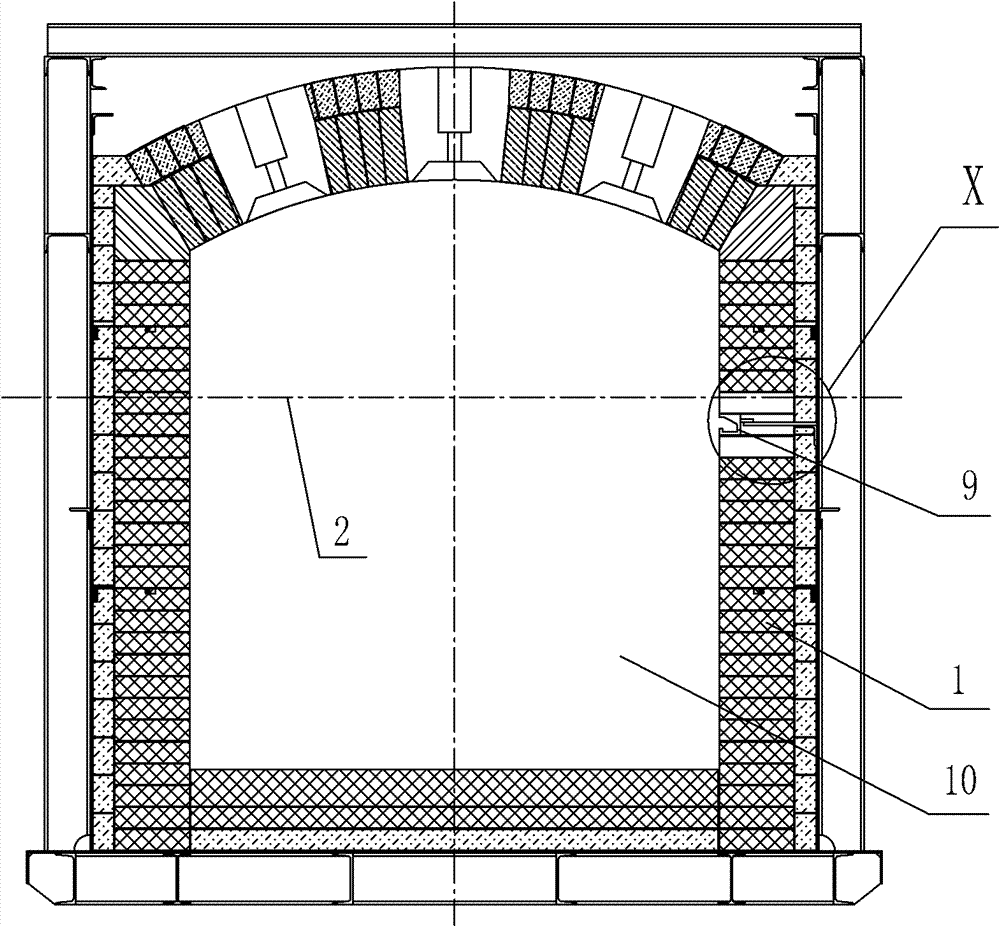

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the belt threading method of strip steel in silicon steel continuous annealing drying furnace, it comprises the following steps:

[0030] 1) In the inner wall of the furnace wall of the silicon steel continuous annealing drying furnace, a heat-resistant steel groove part 9 is arranged along the moving direction of the strip steel. The distance between the center line of the heat-resistant steel groove part 9 and the strip steel passing line 2 is 0~ 500mm (that is, 0-500mm higher than the strip steel passing line, or 0-500mm lower than the strip steel passing line), the heat-resistant steel groove part 9 is provided with a concave groove along the moving direction of the strip steel; the silicon steel is continuously annealed and dried The entrance support frame is fixed on the furnace wall of the furnace entrance (that is, the entrance support frame is located at the entrance end of the furnace wall), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com