Surface-carved co-extruded profile

A technology of extruded profiles and co-extruded layers, which is applied in the field of surface-carved co-extruded profiles, can solve problems such as adhesion constraints and low market acceptance, and achieve the effect of improving decoration and eliminating dazzling dizziness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

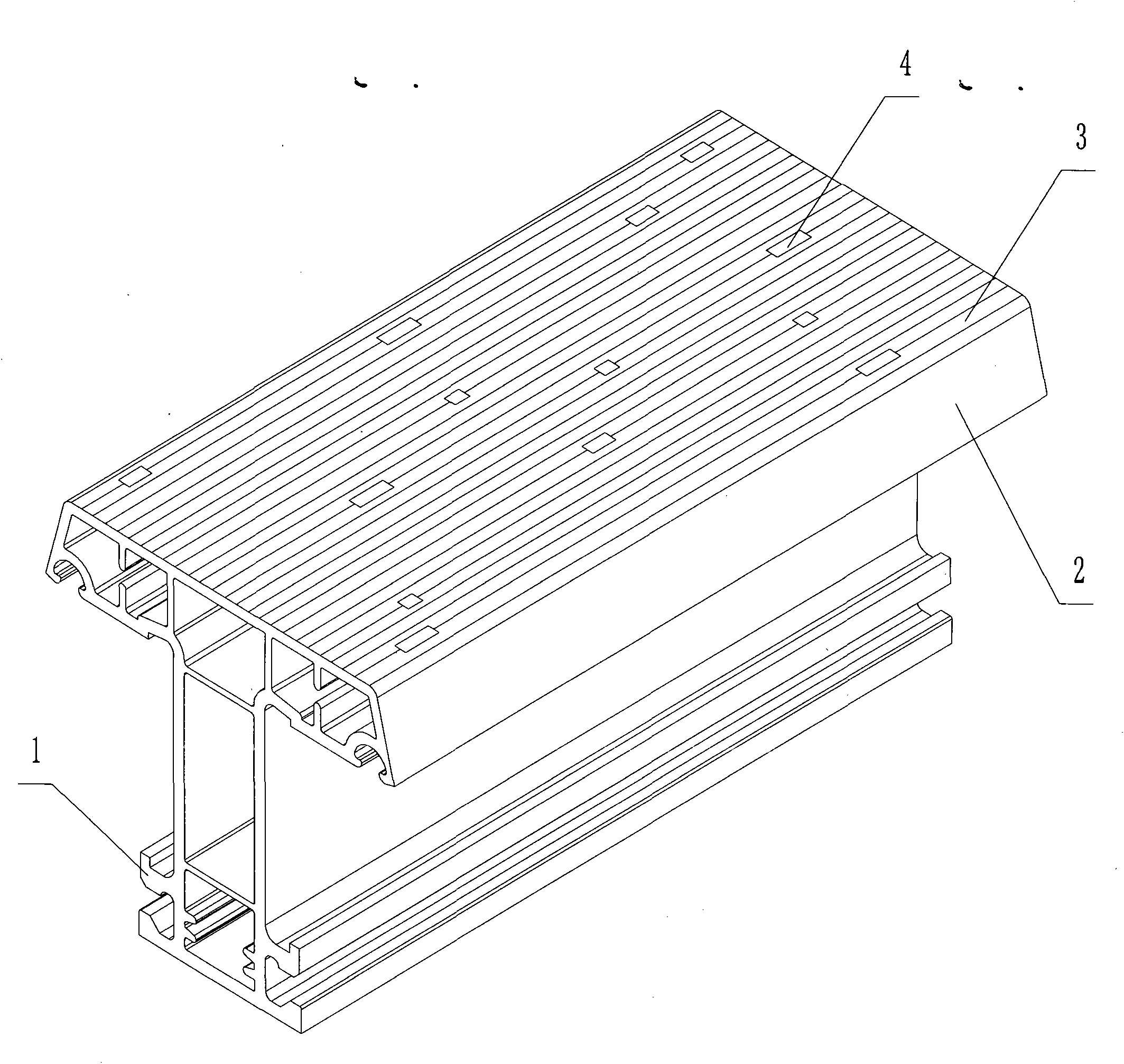

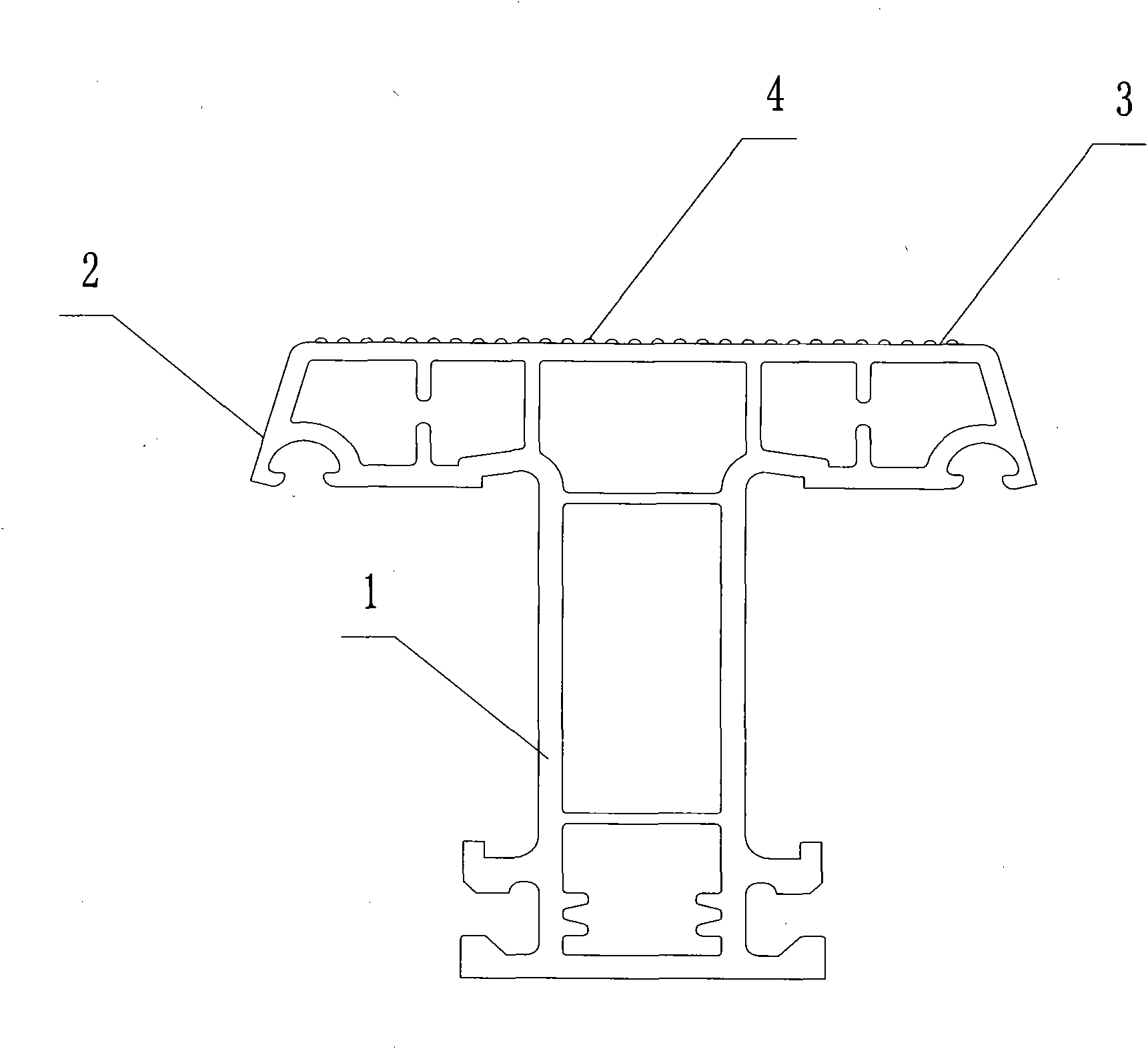

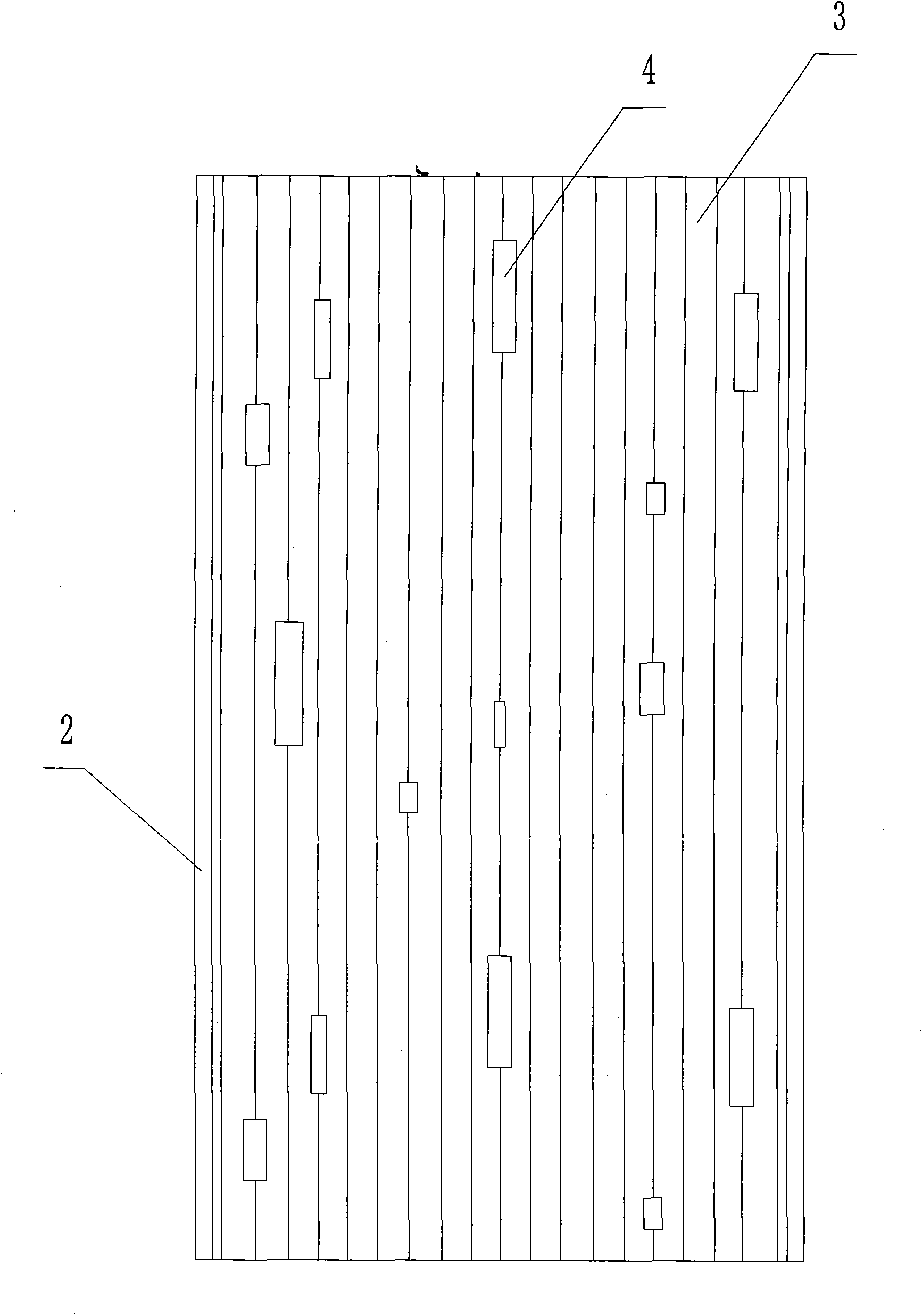

[0017] Such as figure 1 As shown, a surface-carved co-extrusion profile of the present invention is compounded by a co-extrusion profile matrix 1 and a co-extrusion profile co-extrusion layer 2. The co-extrusion profile co-extrusion layer 2 is an ASA layer or a PMMA layer, and its thickness is 0.3mm. The surface plane distribution of the co-extrusion profile co-extrusion layer 2 is the concave groove 3 and the convex line 4 pressed out by the knurling roller. In the figure, the groove 3 and the convex line 4 are linear, and the groove 3 can also be a curve or a line segment or Combination of curves and line segments, convex line 4 can also be a combination of curve segments or points or multiple lines and points. The grooves 3 are arranged in an orderly manner along the length direction of the profile, and the grooves 3 are arc-shaped on the vertical cross section, and the grooves 3, the convex strips 4 and the co-extrusion layer 2 of the co-extruded profile are of the same co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com