Joint connector, wiring harness and method for assembling the joint connector

A joint connector, connector technology, applied in the direction of the parts of the connecting device, the connecting contact material, the two-part connecting device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

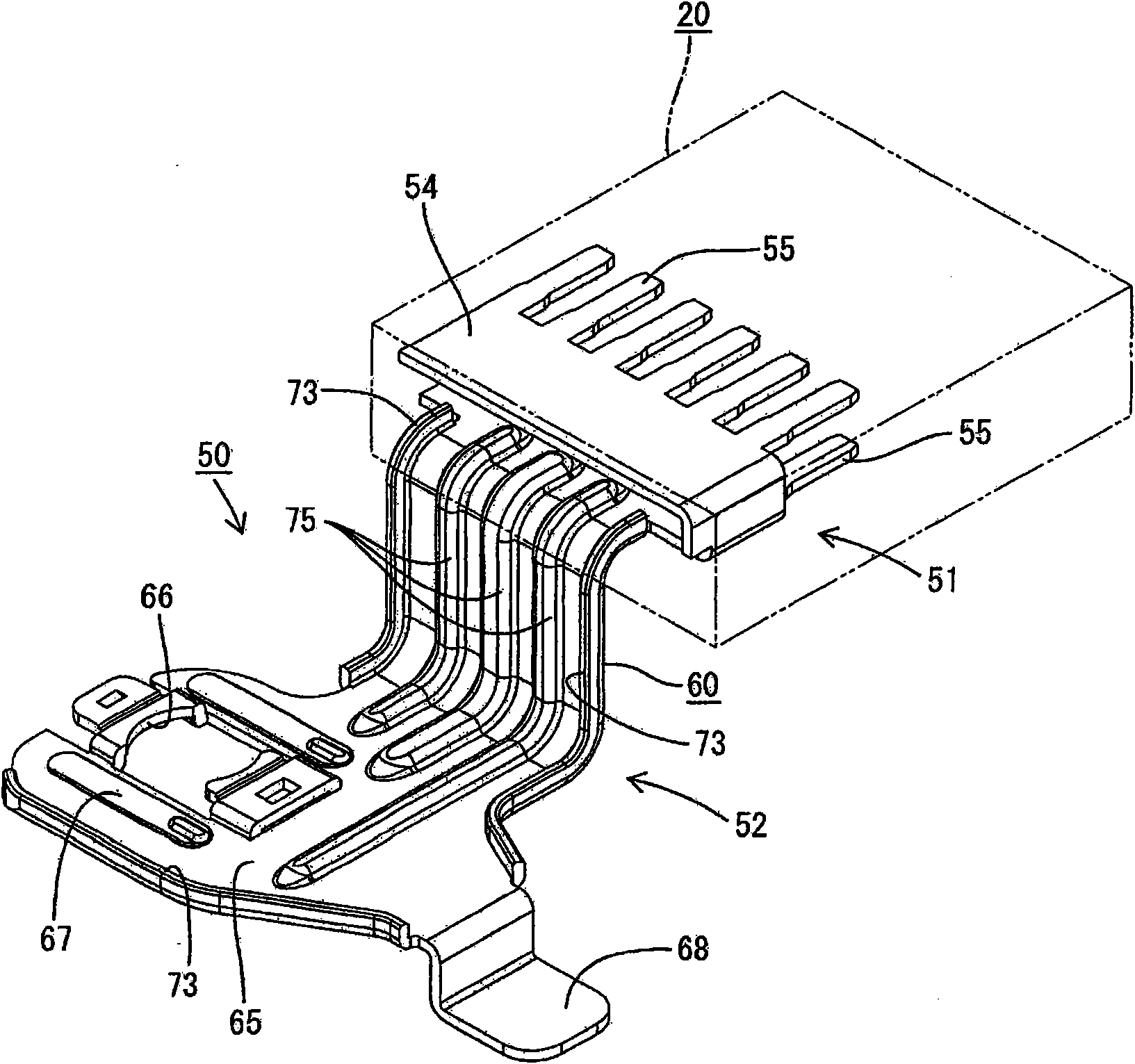

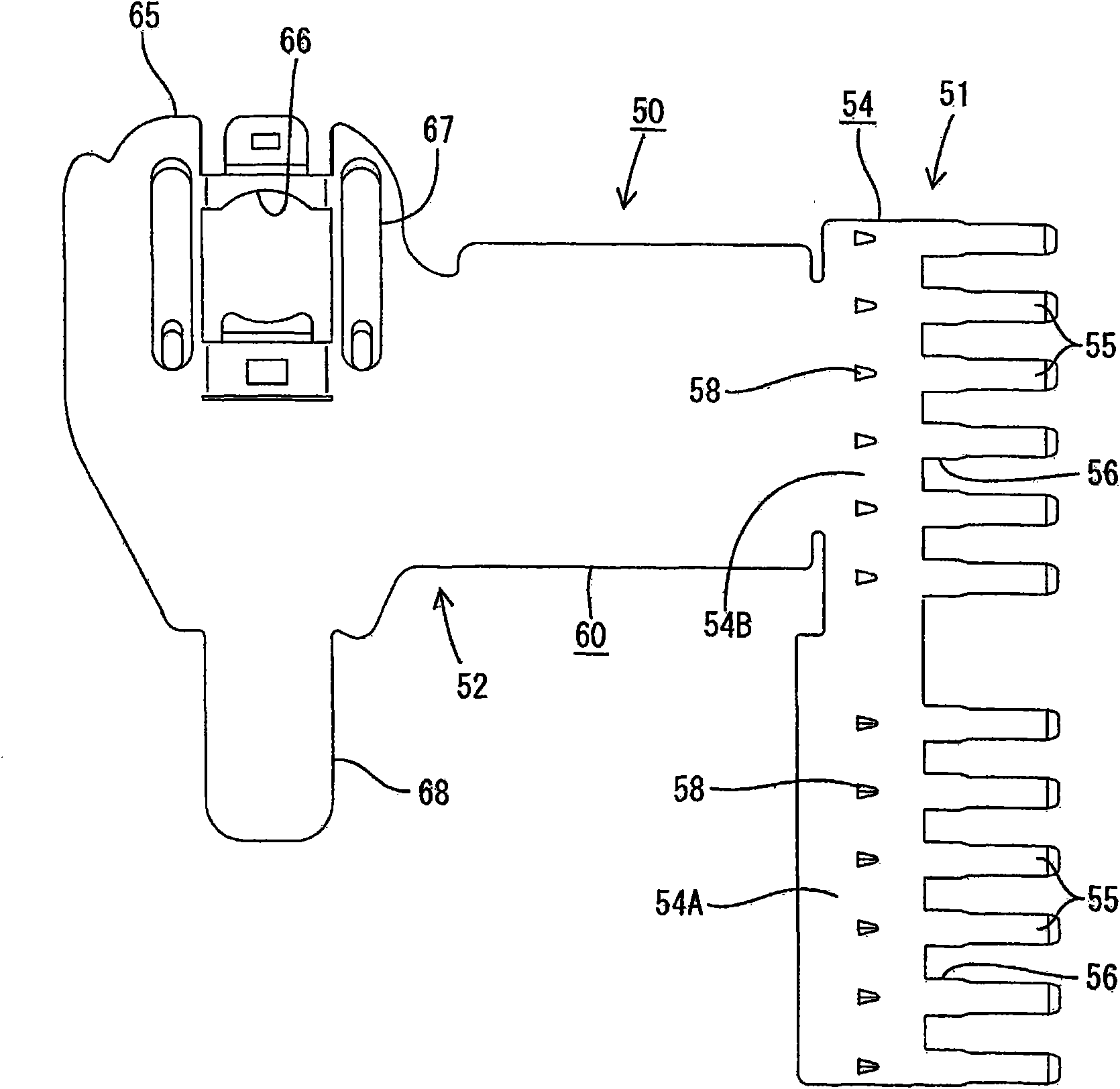

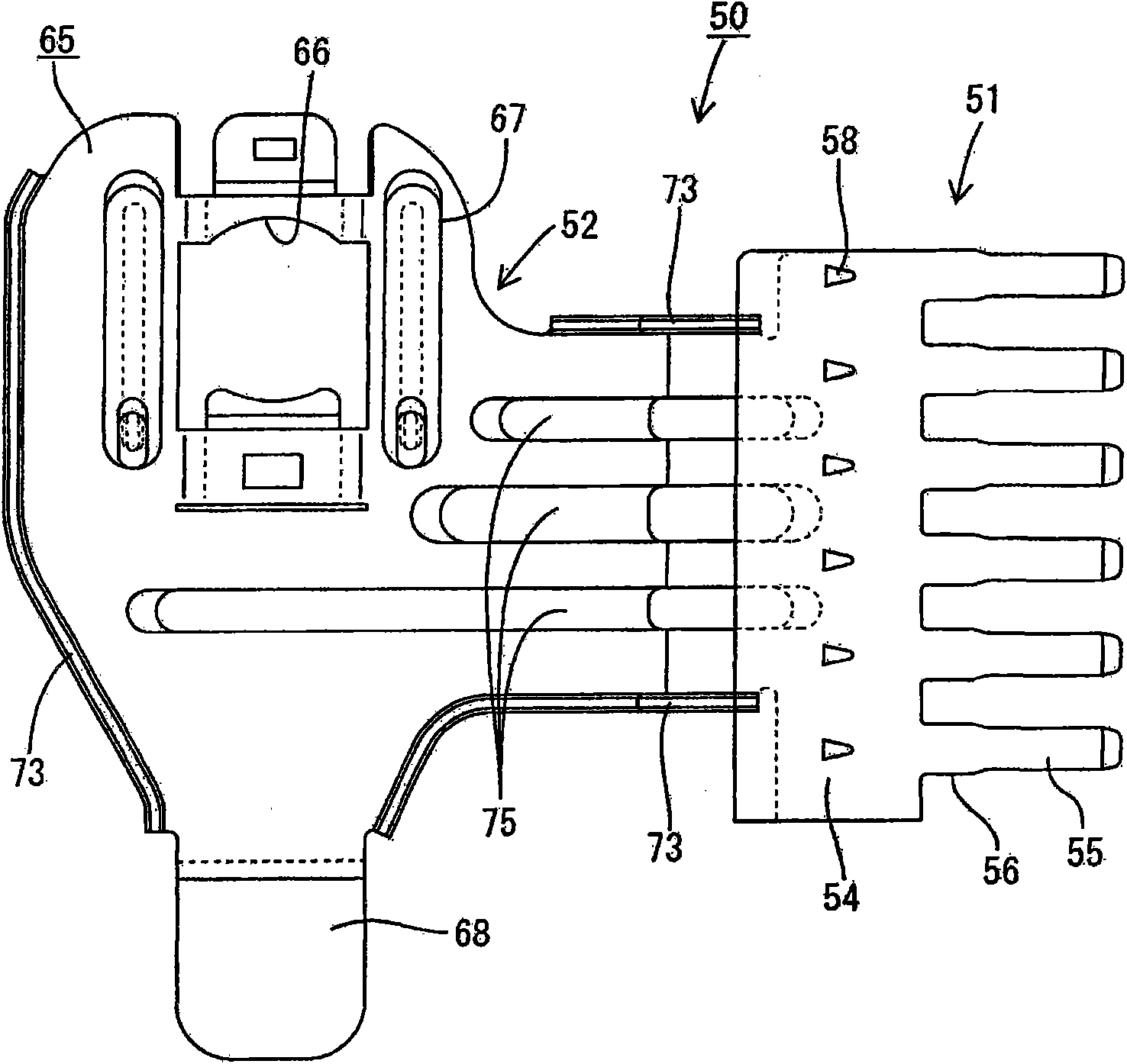

[0077] refer to Figure 1 to Figure 18 An embodiment of the present invention will be described.

[0078] The joint connector JC of this embodiment is configured such that the male terminal portion 51 of the joint terminal 50 is installed in the front side of the connector housing 20, and is connected to one or more female terminals on one or more ends of each ground wire 10. 11 is installed into the connector housing 20 (preferably substantially from the rear) so as to be connected to one or more corresponding male terminals 55 provided in the male terminal portion 51, as figure 1 with Figure 9 As shown in , and the bracket 52 of the connector terminal 50 is to be mounted on the ground of the vehicle.

[0079] The connector housing 20 (hereinafter simply referred to as "housing 20") is made of synthetic resin, for example, and / or is substantially as Image 6 with Figure 7 The platform form shown in . Roughly speaking, the front side ( Figure 7 The left side in ) is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com