O-shaped anti-skidding cable plywood for coal mining machine

A cable splint and anti-slip technology, which is applied in the direction of cable arrangement between relative moving parts, cable installation, electrical components, etc., can solve problems such as damage, difficult work of shearer power supply cable protection, and cable anti-slip issues that have not been mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

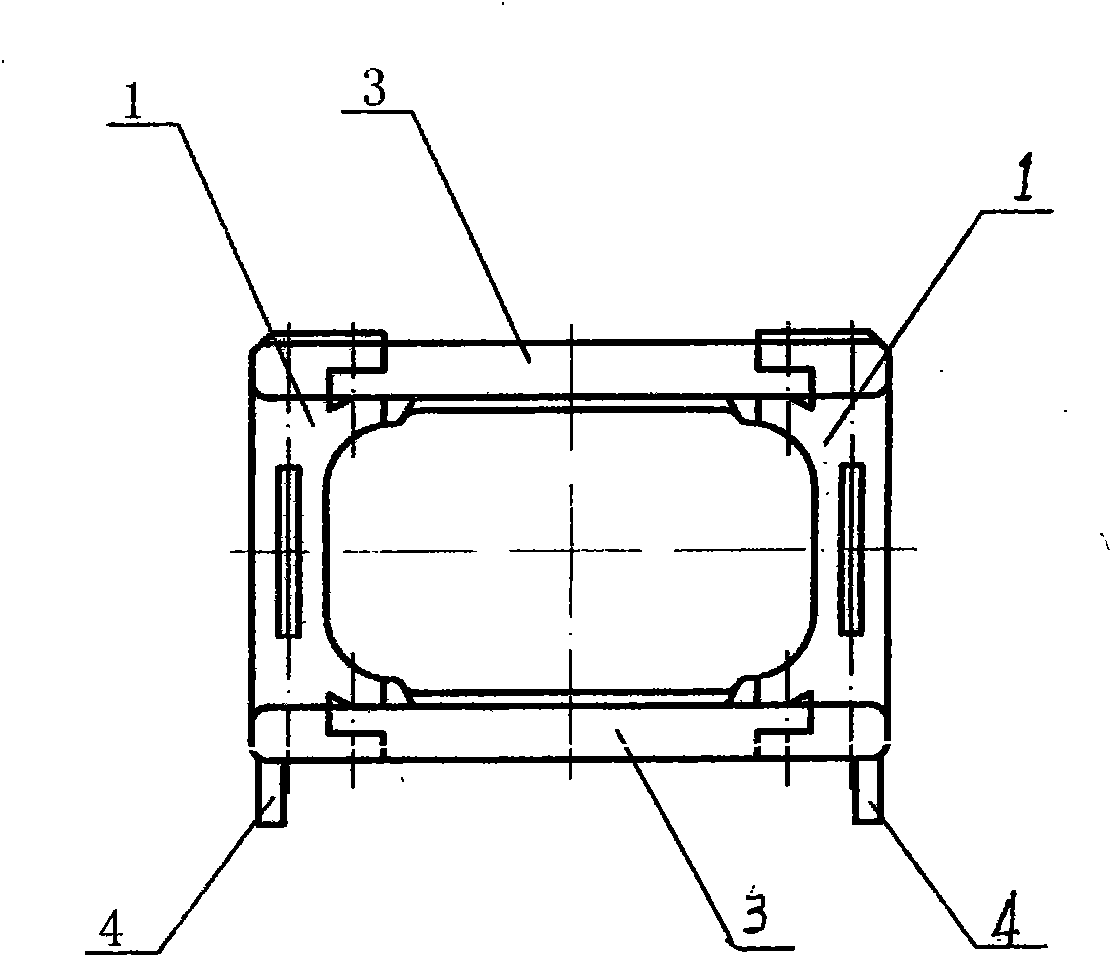

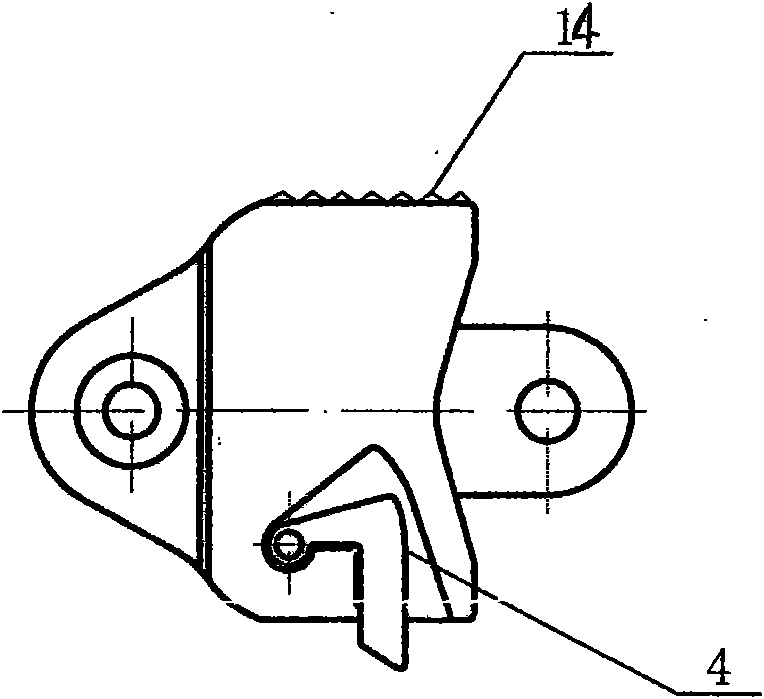

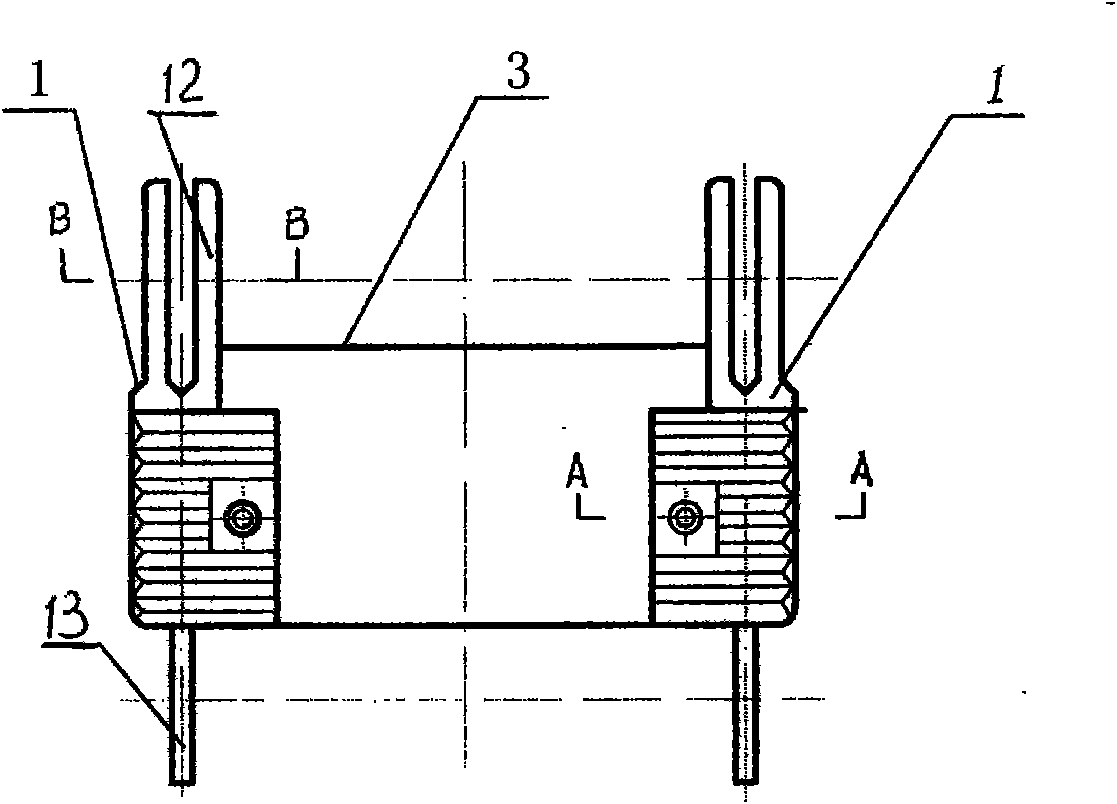

[0011] Such as Figure 1~5 As shown, an O-shaped anti-skid cable splint for a coal shearer includes a cable splint composed of left and right support plates 1 and upper and lower connecting plates 3 of a steel core injection molding structure. The upper and lower ends of the left and right support frames are respectively provided with symmetrical tenon grooves 11, and the front and rear ends are respectively provided with metal connecting forks 12 and connecting pieces 13. The left and right ends of the upper and lower connecting plates are respectively provided with tenons 31 that match and combine with the tenons and grooves on the left and right supporting frames. The mortise and tenon matching junction is connected and riveted by pin 6. The tops of the left and right two support frames are respectively provided with triangular anti-skid teeth 14, and the lower part is provided with an open cavity respectively in the middle position. A non-return pawl 4 approximately in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com