Device and method for dragging dust removal fan through industrial boiler steam

A dust removal fan and industrial boiler technology, which is applied in the direction of steam engine installation, machine/engine, process efficiency improvement, etc. It can solve the problems of reducing the service life of the system, wasting power, affecting the normal operation of the system, etc., so as to save electric energy and avoid wasting energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

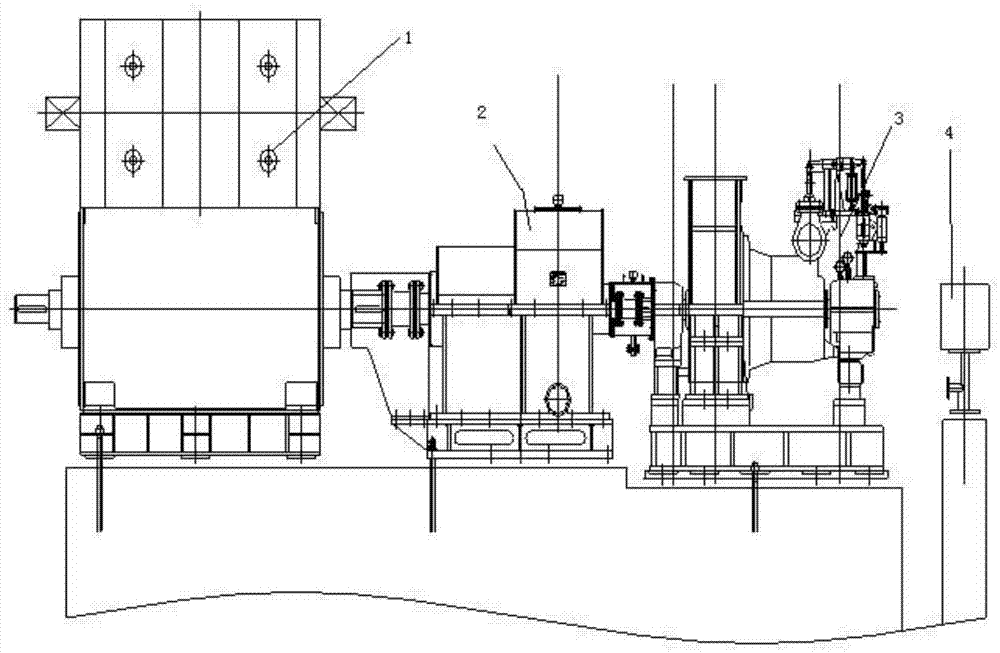

[0024] The industrial boiler steam provided in this embodiment is used to drive the device and method of the dust removal fan, so that the steelmaking can produce about 20t / h of saturated steam during normal production, and the steam drum steam pressure is 1.5MPa, and the steam generated passes through the heat accumulator The pressure is stabilized, and the external steam pressure is 1.3MPa as an example to carry out steam drag transformation on the dust removal fan in the factory.

[0025] Fan parameters: model: Y4-2x60-14 No.33.2F; flow rate: 1200000m 3 / h

[0026] Speed: 740r / min; Total pressure: 6000Pa; Rotation direction of the dust removal fan: Standing on the side of the motor, the rotation direction of the fan is counterclockwise. (Use this as the basis for the design of the reducer)

[0027] Motor parameters: speed: 745r / min; power: 2800KW; voltage: 6000V; the motor adopts high voltage frequency conversion;

[0028] In addition, a 2748KW low-pressure saturated st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com