Liquid recovery device and liquid recovery method by using same

A liquid recovery and liquid recovery technology, which is applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of increasing production costs, environmental pollution, and increased viscosity of the recovered liquid 37

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

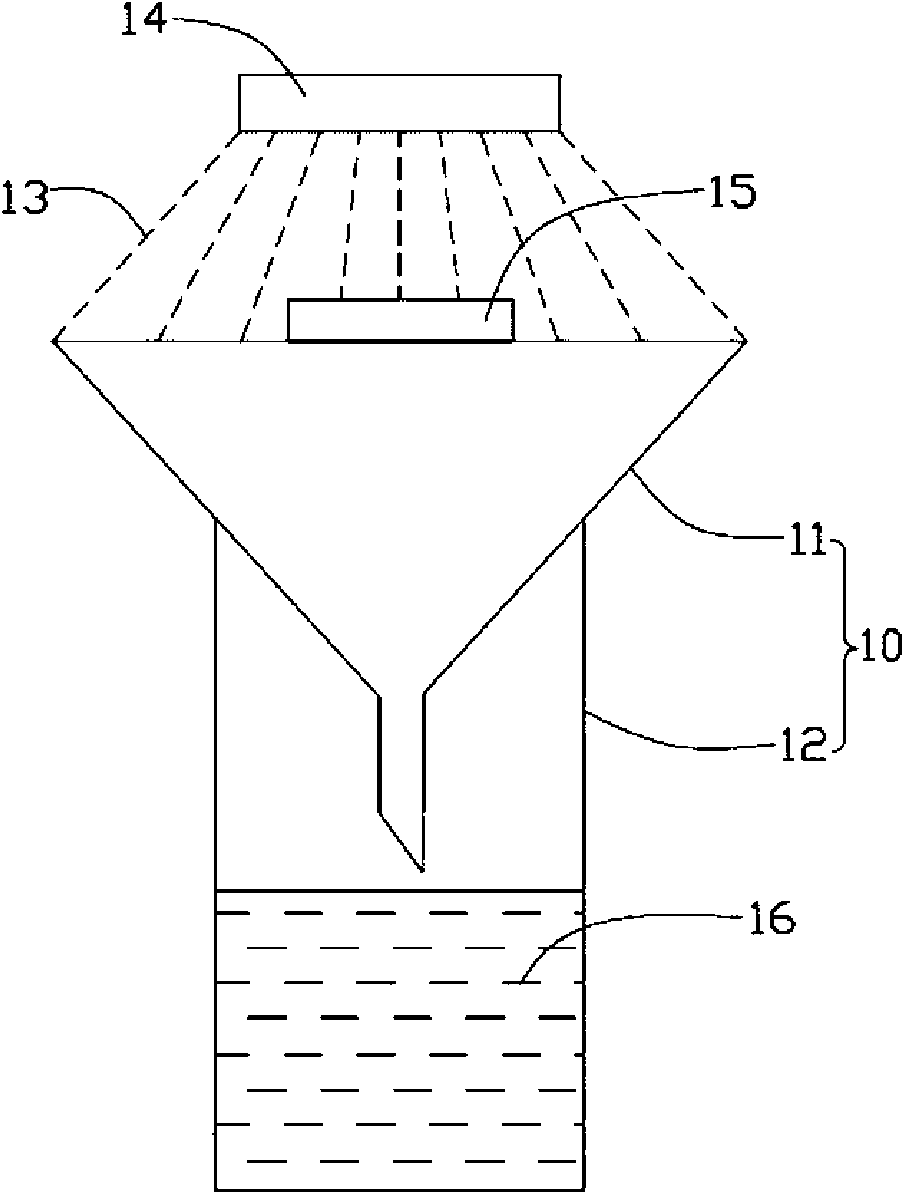

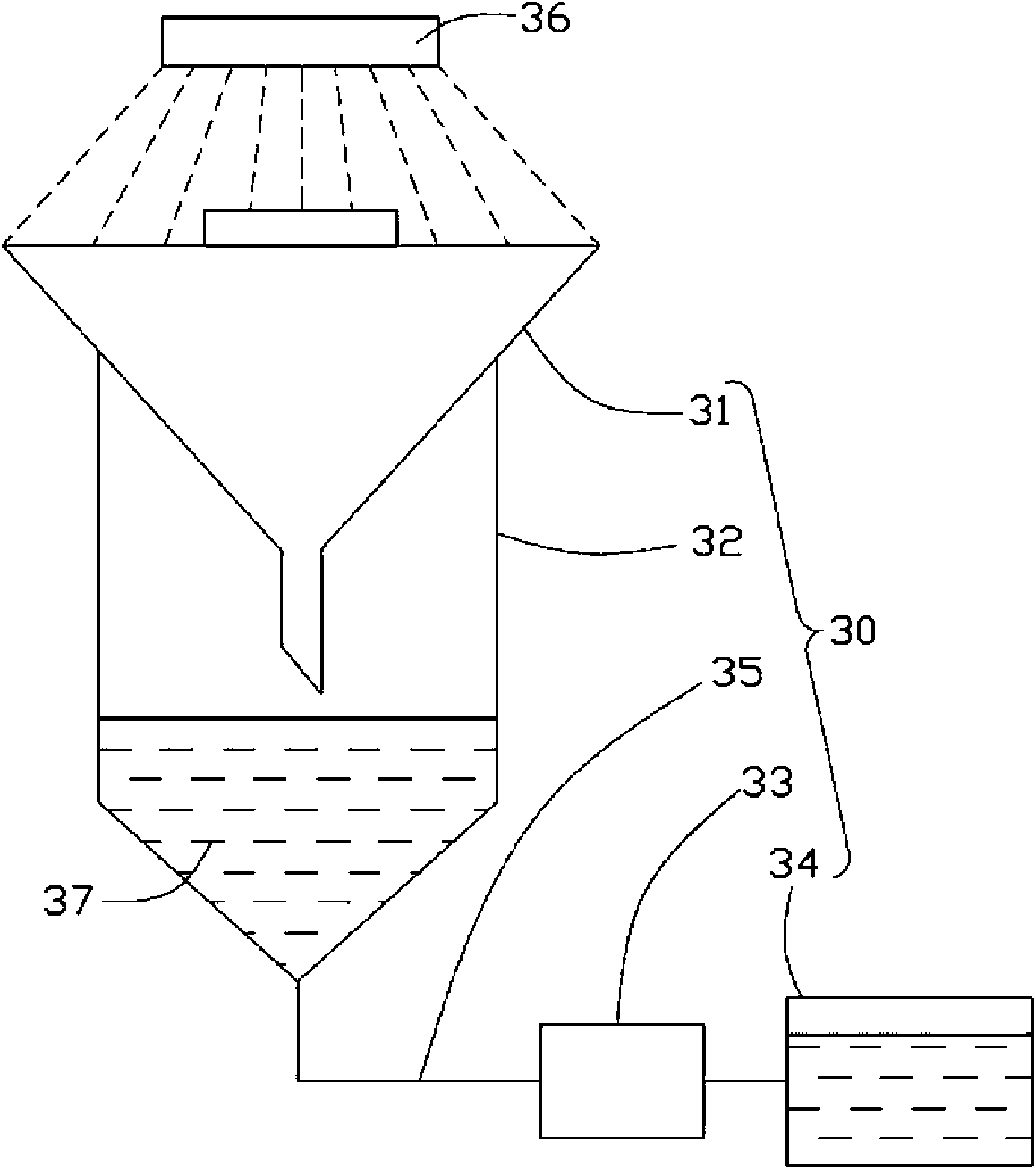

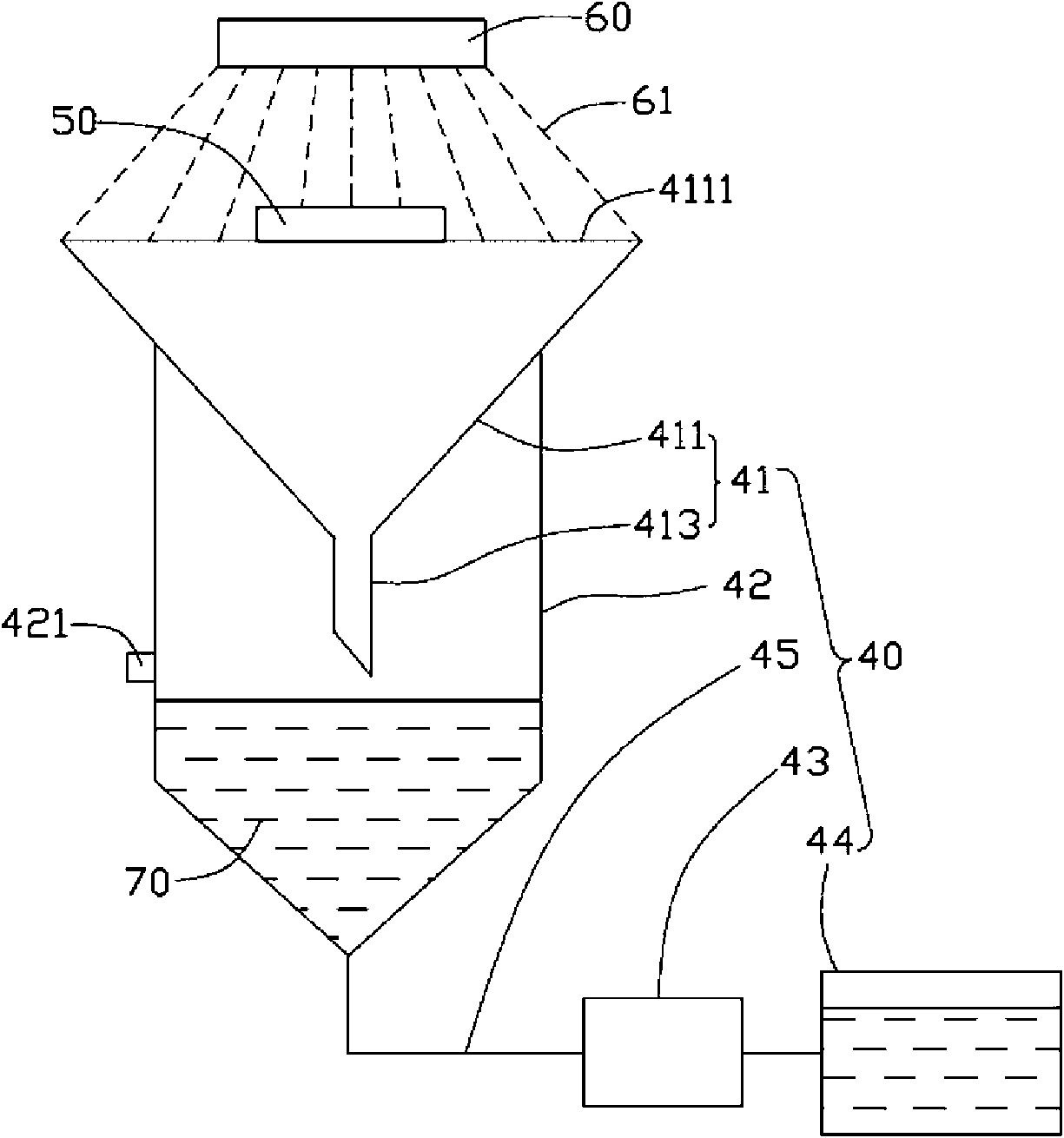

[0020] The liquid recovery method of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The liquid recovery method of the present invention can be used in production processes such as cleaning and painting. In this embodiment, the recovery of paint is described in the painting process.

[0021] see image 3 , a liquid recovery device 40, including a funnel 41, a collection box 42, a recovery pump 43, a liquid storage bottle 44 and a pipeline 45 connecting the collection box 42, the recovery pump 43 and the liquid storage bottle 44 in turn, and one end of the funnel 41 is inserted into the collection box 42 . The funnel 41 of the liquid recovery device 40 is aimed at the workpiece 50 , and the paint spraying device 60 is disposed on the other side of the workpiece 50 and aimed at the workpiece 50 , and the paint spraying device 60 sprays the paint 61 on the workpiece 50 .

[0022] The funnel 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com