Protective device for cleaning machine

The technology of a protective device and cleaning machine is applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of motor safety failure, inconvenient wire installation, and large space occupation, and achieve stable and safe lifting, convenient wire installation, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

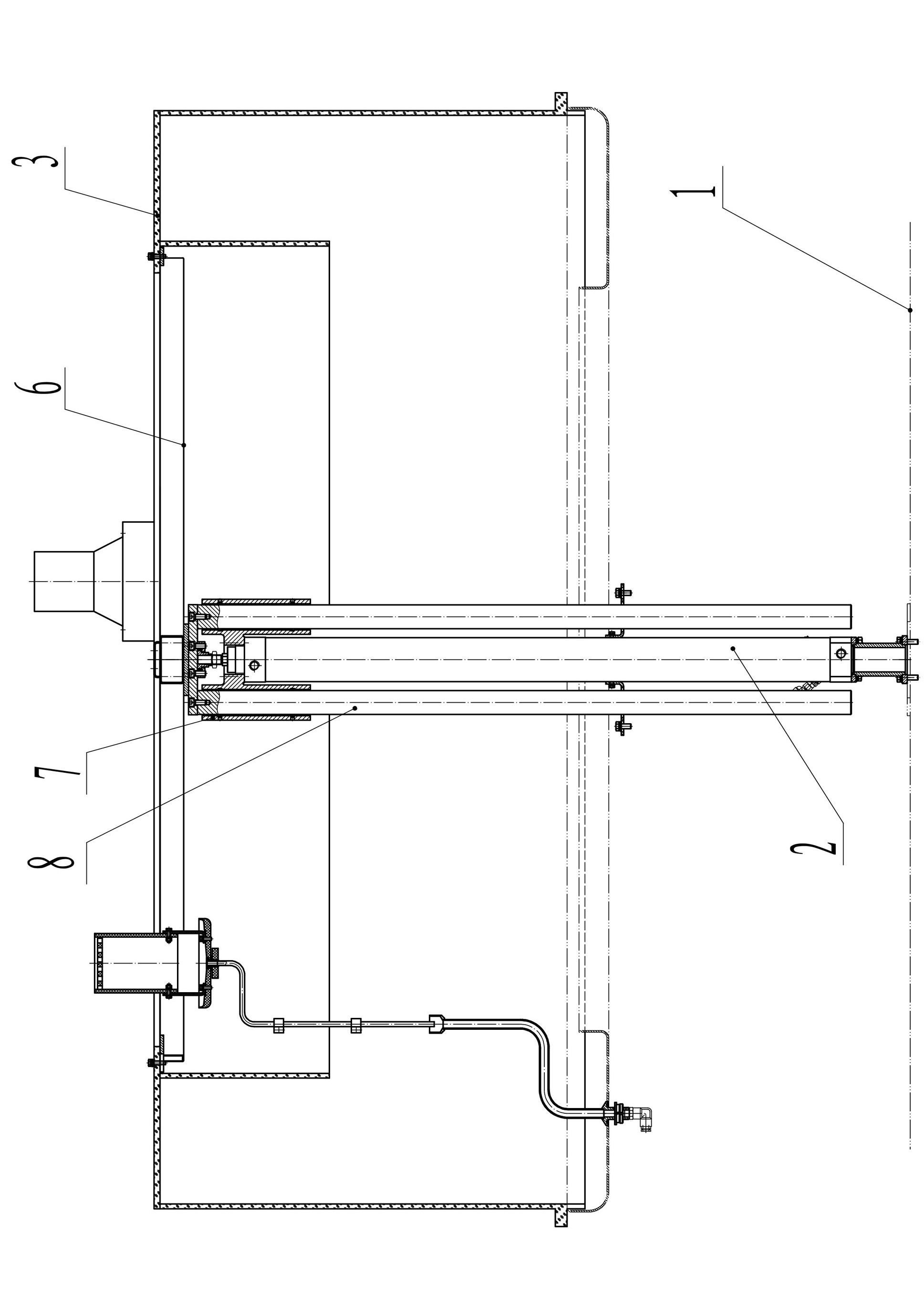

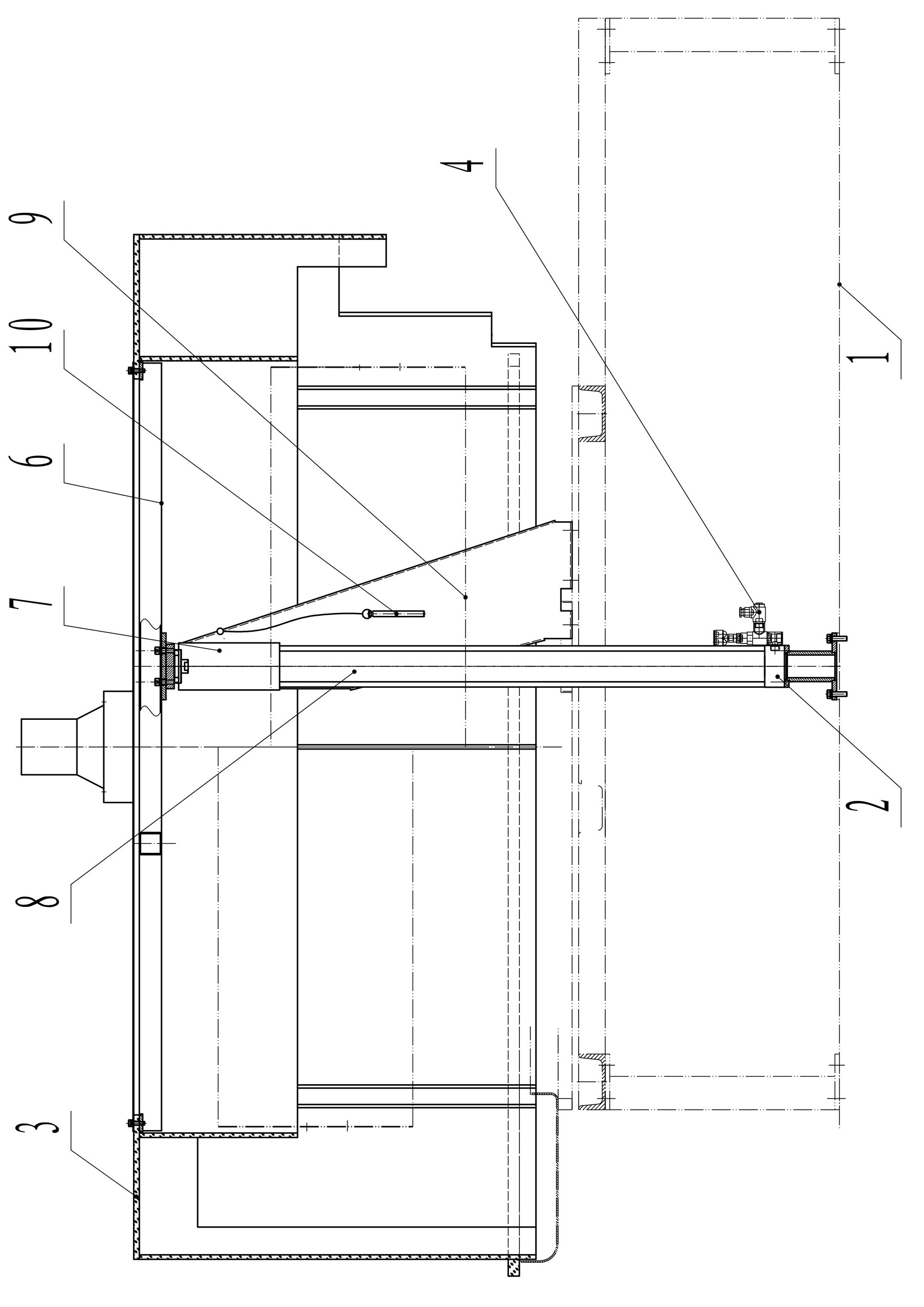

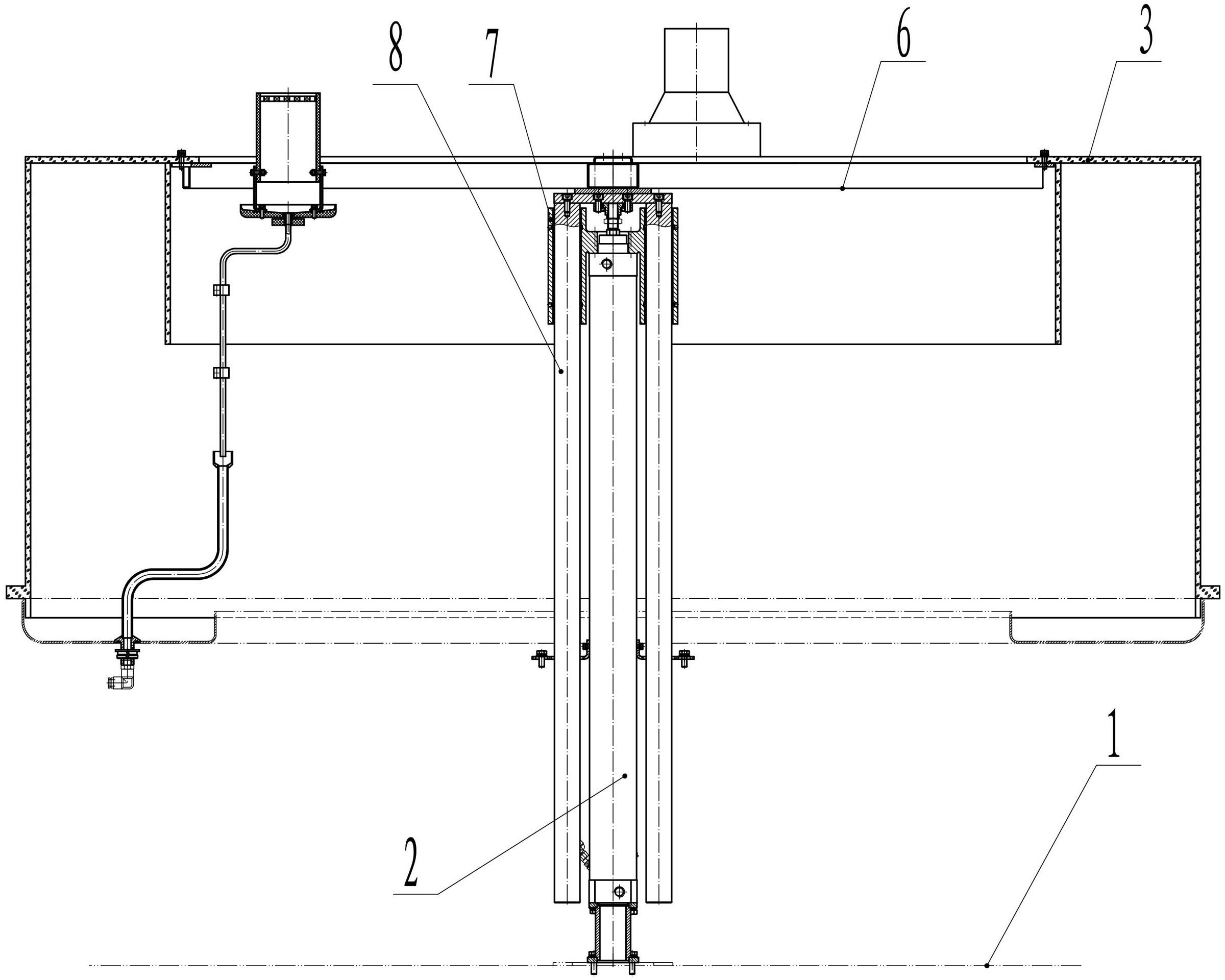

[0018] like figure 1 and figure 2 As shown, the protective device for washing machine of the present invention includes a frame 1, a protective cover 3 and a drive cylinder installed on the frame 1 for driving the protective cover 3 to lift, and the protective cover 3 is connected to the telescopic end of the drive cylinder. More than one guide mechanism is arranged along the peripheral side of the cylinder outer wall of the driving cylinder. The protective cover 3 lifts under the driving of the drive cylinder and the stable guidance of the guide mechanism, so as to realize the setting and opening of the cleaning machine. Since the guide mechanism is installed close to the drive cylinder, most of it is in the protective cover, which can effectively save space, reduce the occupied area, and make the structure more compact. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com