MEMS (micro electro mechanical system) device and wafer-level vacuum packaging method thereof

A wafer-level and device technology, which is applied in the field of MEMS devices and wafer-level vacuum packaging of MEMS devices, can solve the problems of complex process, high cost, short vacuum holding time, etc., and achieves simple process, reliable performance, and long vacuum holding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

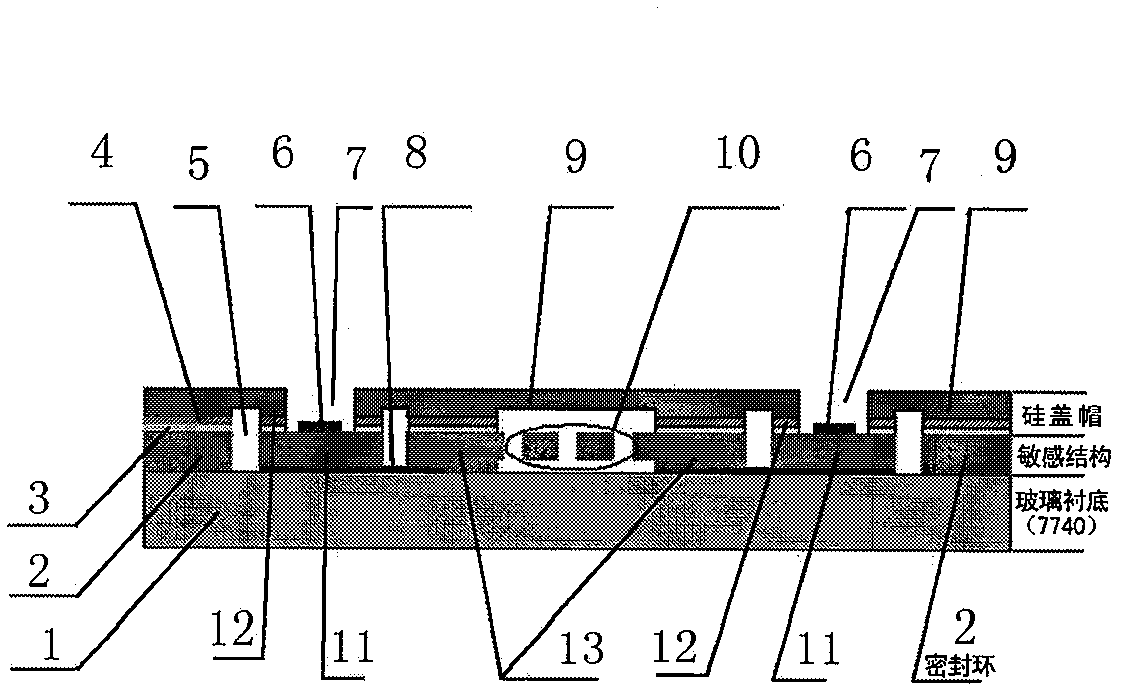

[0031] 1. The structure of MEMS devices:

[0032] See attached figure 1 , a MEMS device provided by the present invention, a group of MEMS devices are produced on a silicon wafer, and each MEMS device is composed of a glass substrate 1, a silicon chip sensitive structure layer with a sealing ring 2 and a silicon cap 9.

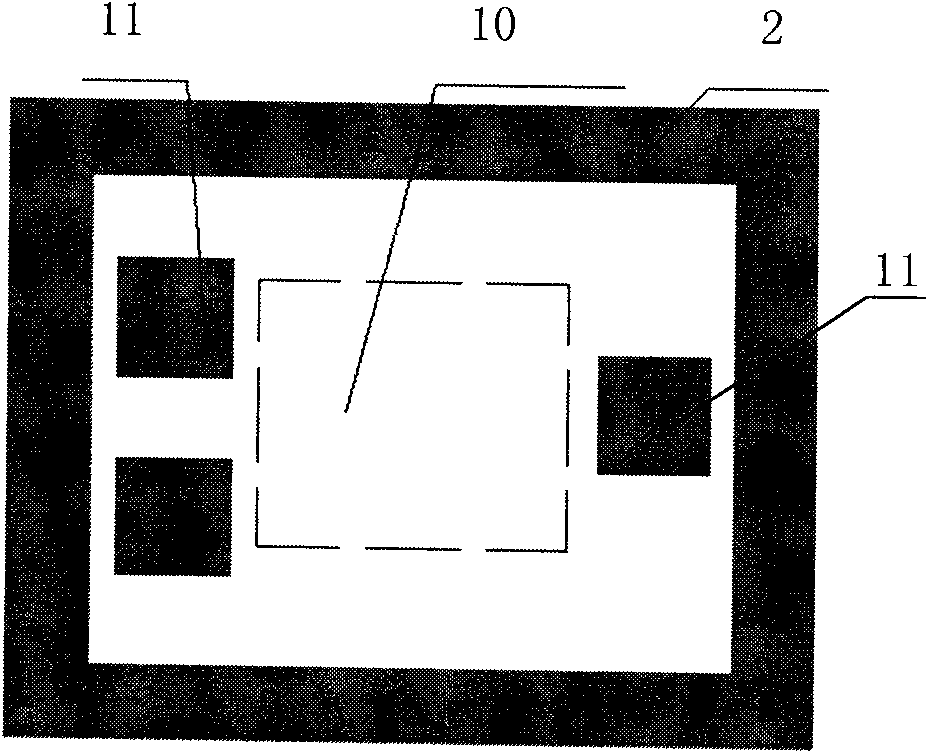

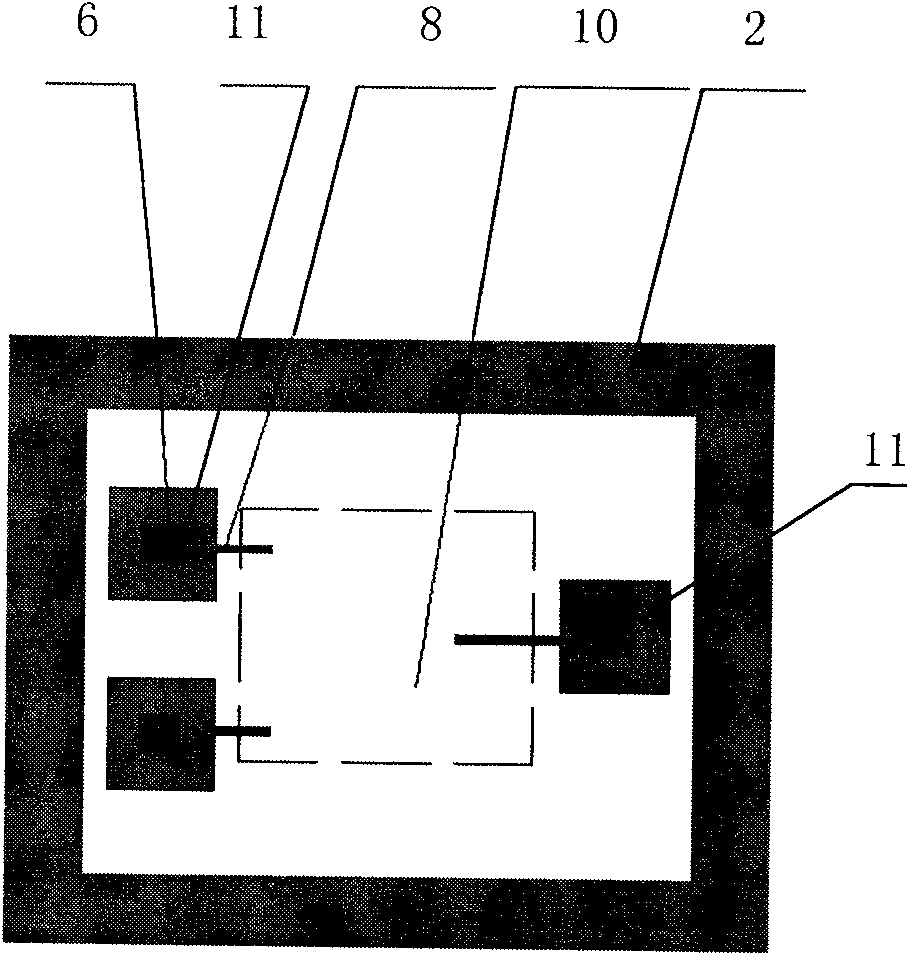

[0033] Three silicon islands 11 are arranged in the sensitive structure layer of the silicon chip (silicon islands are set according to the number and position of the bonding pads, and the present embodiment is designed as three silicon islands), and each silicon island 11 is isolated from other components of the sensitive structure layer. Insulation, the bottom of each silicon island 11 is respectively connected to the glass substrate 1 and an electrode lead 8 arranged on the glass substrate, each silicon island 11 is respectively provided with a bonding point 6; the silicon cap is connected to each silicon island The corresponding positions are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com