Box girder positioning temporary supporting seat and positioning construction method of box girder

A technology of temporary support and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of obvious shaking of the gondola, large error, and can only reach about 10 centimeters, so as to improve construction accuracy and ensure The effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

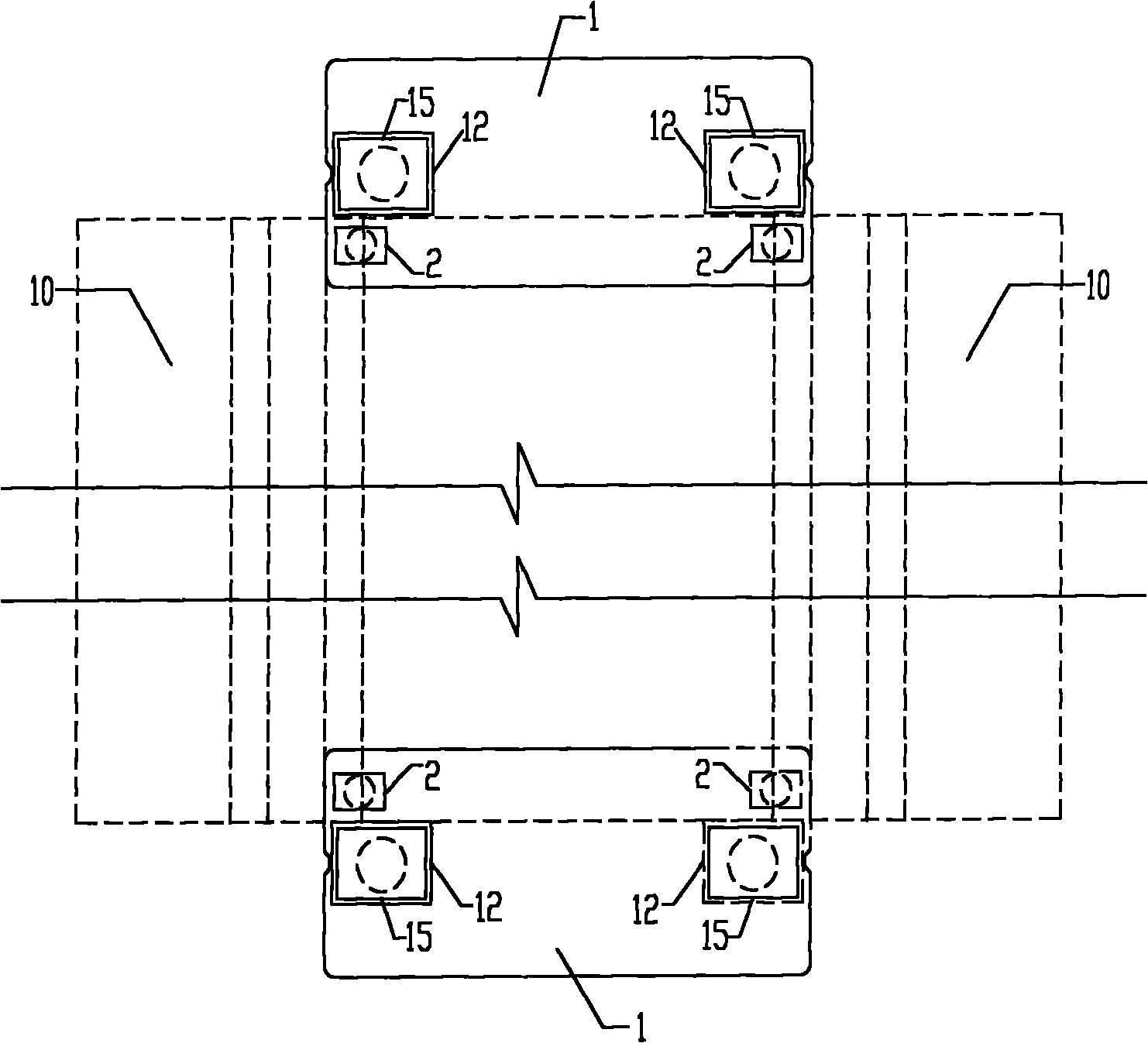

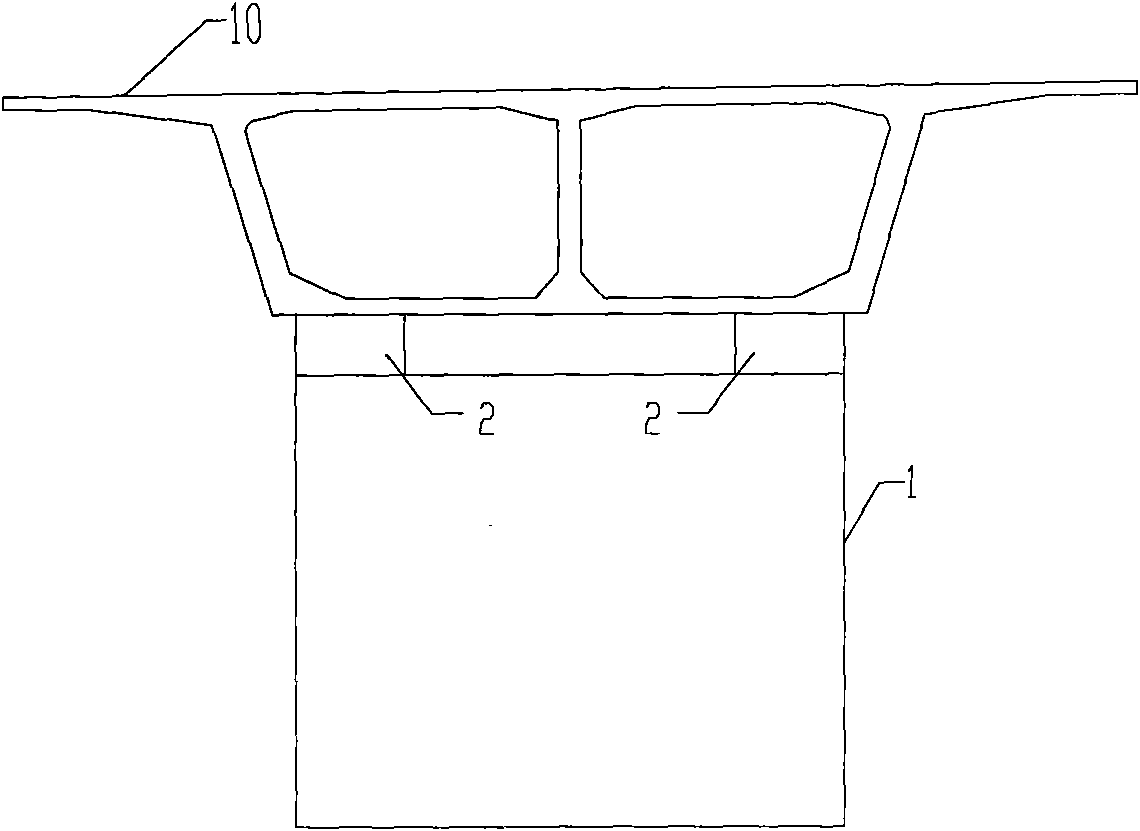

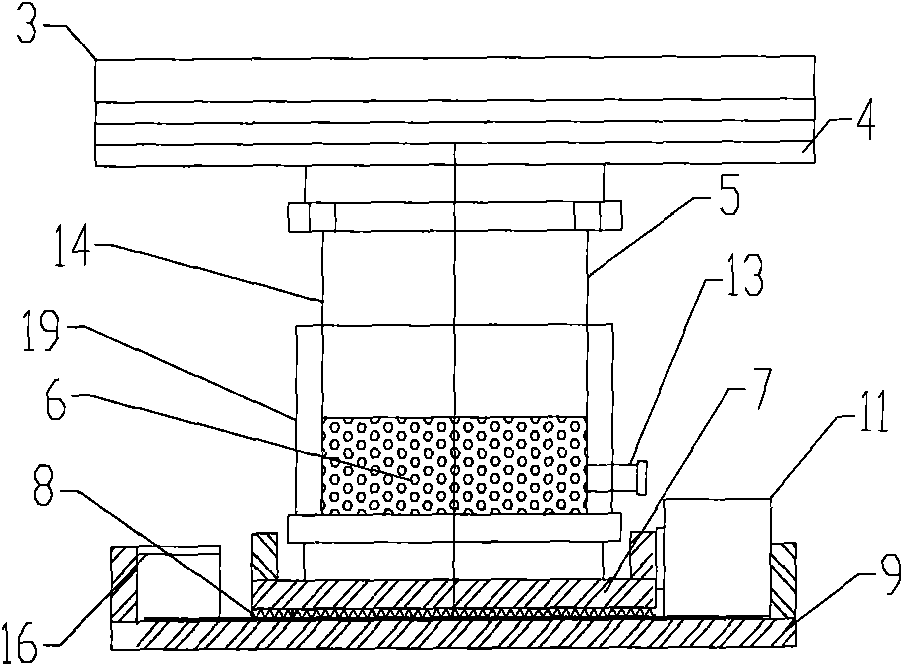

[0028] The manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] Such as image 3 As shown, the box girder positioning temporary support 2 of the present invention includes a steel grit top 5, a base 9 below it and a steel backing plate 4 above it. Wherein, the steel grit top 5 also includes a cylinder 19 and a piston 14 matched therewith, the piston 14 is partly accommodated in the cylinder 19, the part below the piston 14 inside the cylinder 19 is filled with steel grit 6, the side wall of the cylinder 19 The lower end is provided with a quicksand nut 13 for releasing internal steel sand 6, and its side wall has an internally threaded through hole, and the quicksand nut 13 is screwed into the internally threaded through hole. The diameter can not be too large or too small, and the present embodiment selects steel grit with a standard diameter of 2mm. A steel backing plate 4 is laid on the top of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap