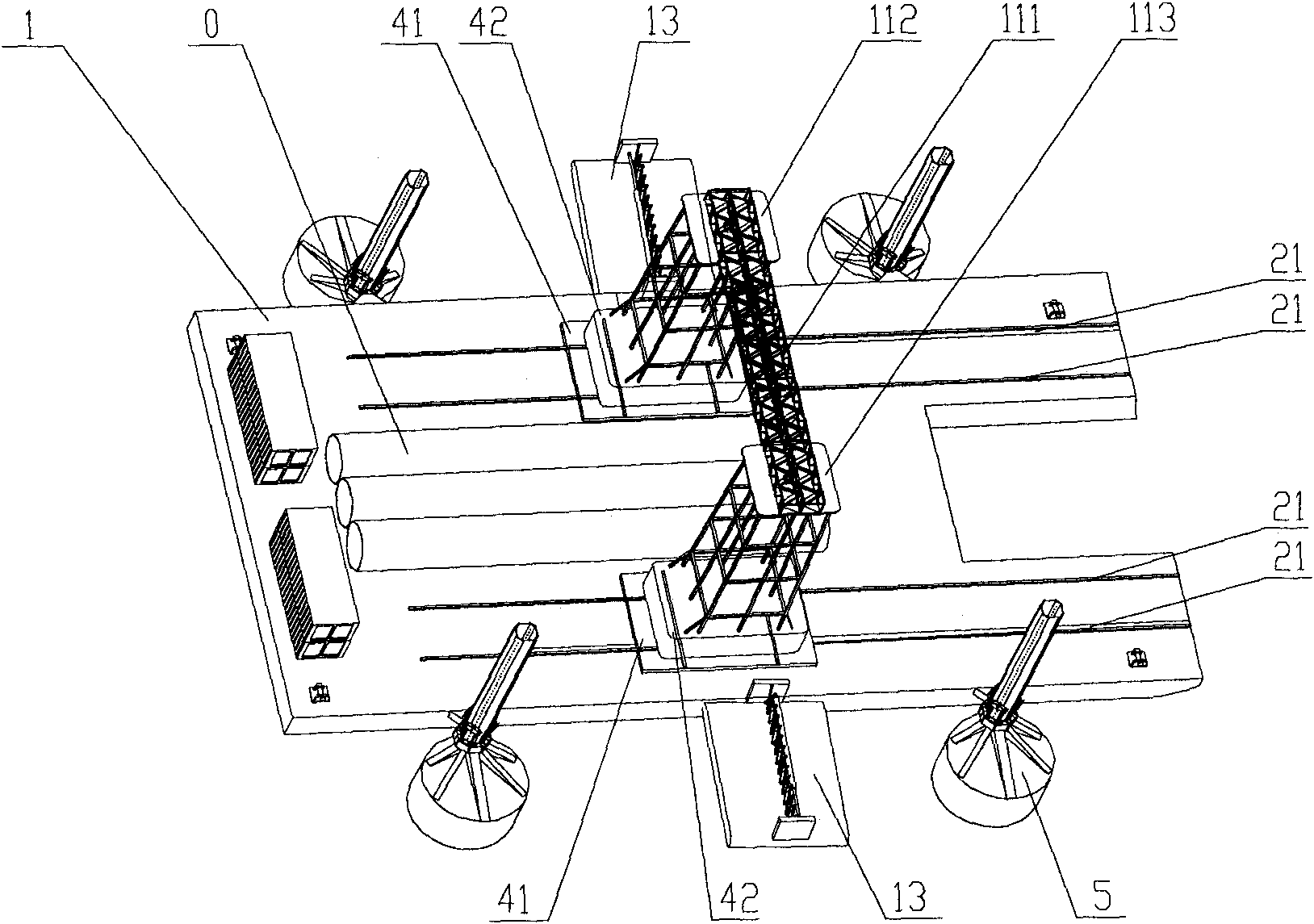

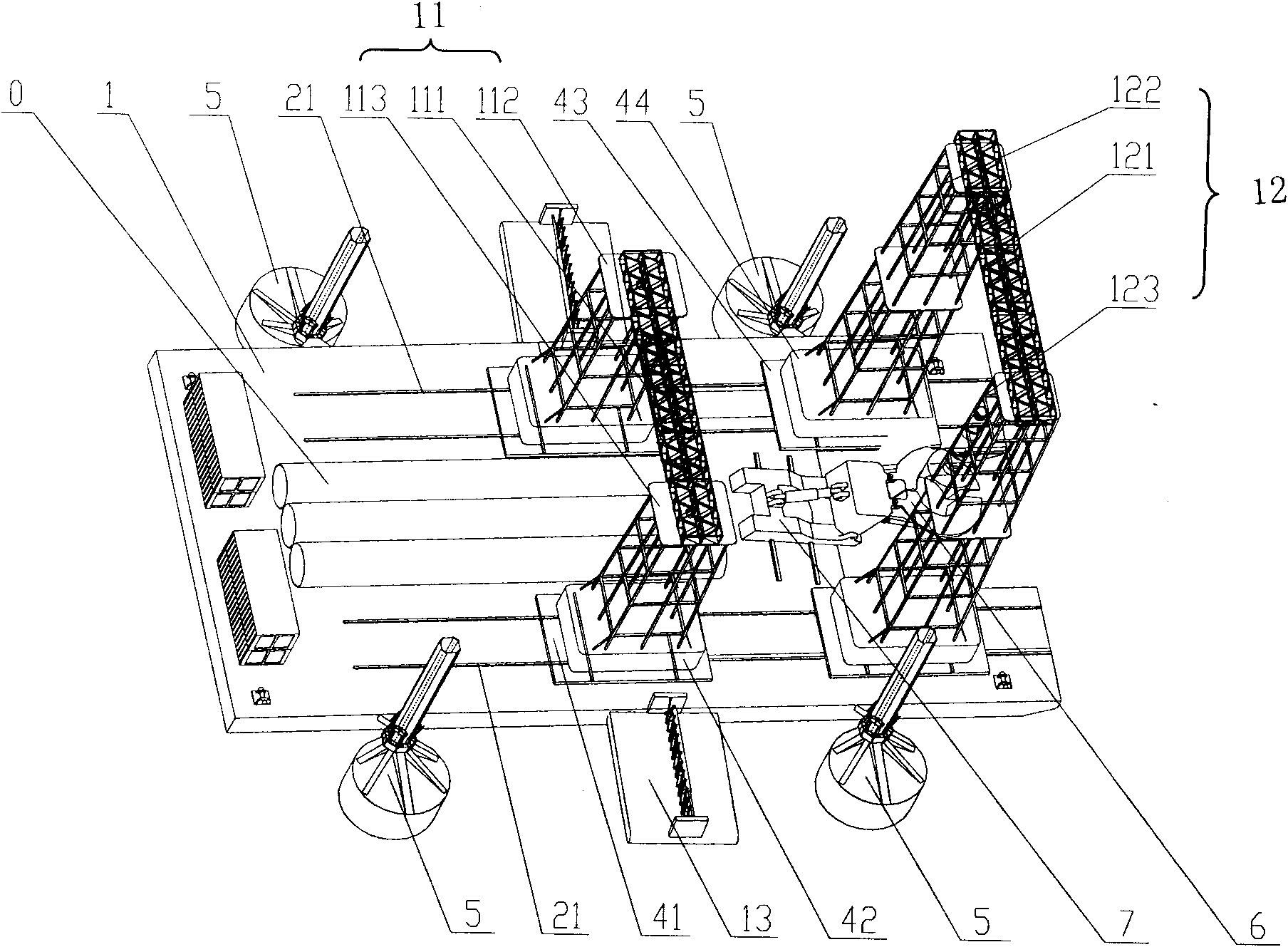

Foundation construction platform for intertidal zone or offshore zone

A technology for foundation construction and infrastructure, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc. It can solve the problem of increasing auxiliary construction equipment, limiting the transition speed of foundation construction platforms, and long auxiliary work time such as picking and transferring piles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

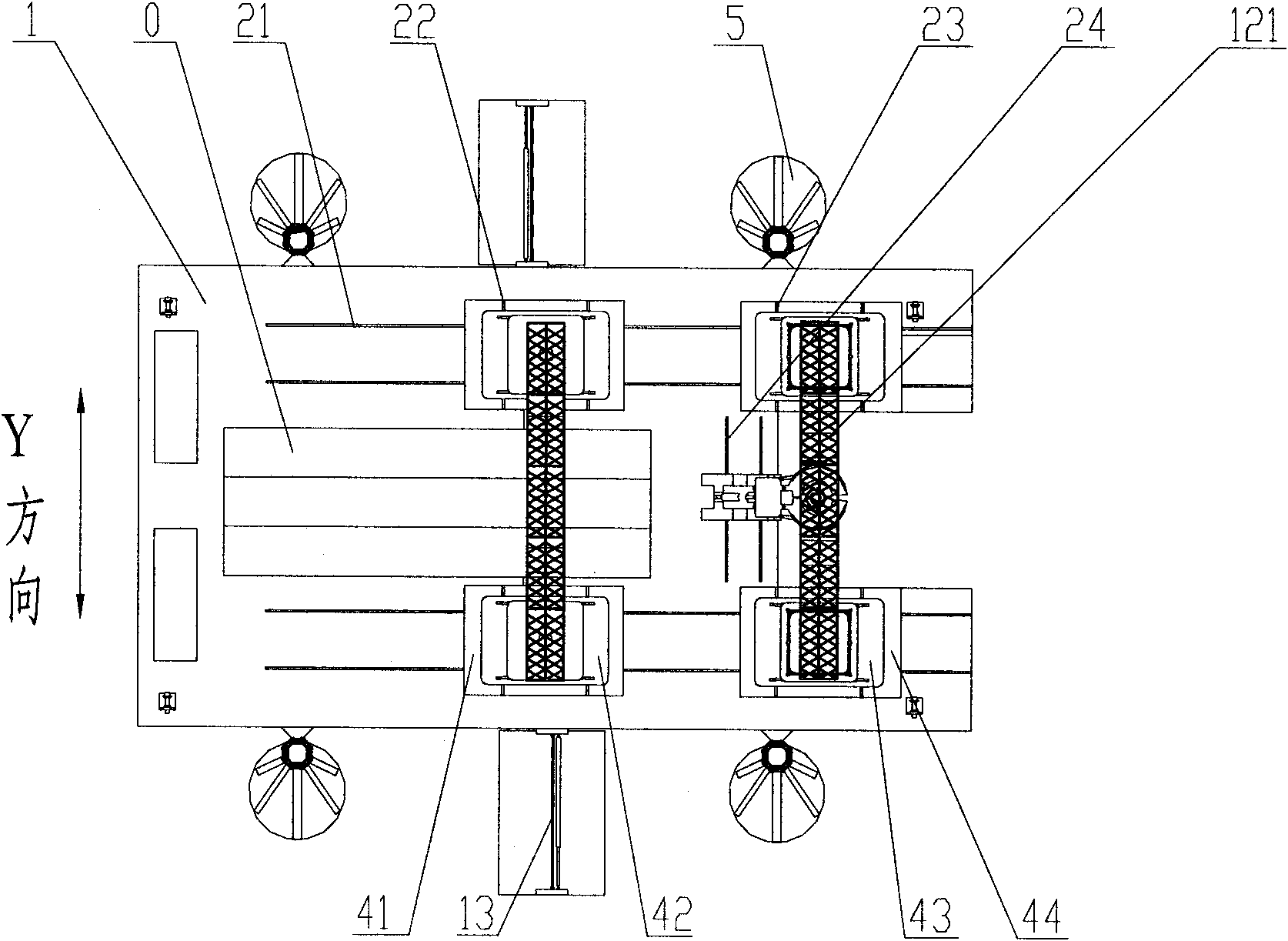

Method used

Image

Examples

specific Embodiment approach

[0058] The above two hoisting devices can move laterally relative to the first beam 111 and the second beam 121 respectively, so that the horizontal movement of the hoisting device and the longitudinal movement of the first lifting frame 11 and the second lifting frame 12 can be achieved. Cooperate with each other, thereby expanding the scope of pipe pile 0 moving.

[0059] Above-mentioned first lifting frame 11 and second lifting frame 12 all can be truss structure, so that under the condition of guaranteeing strength, make first lifting frame 11 and second lifting frame 12 have less self-weight, thereby improve the The hanging pile weight of a lifting frame 11 and the second lifting frame 12. Apparently, the first lifting frame 11 and the second lifting frame 12 are not limited to the truss structure, and can also be other frame structures conventionally used in the field under the condition of satisfying the purpose of use and the working intensity.

[0060] The first lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com