Vertical thin film transistor (TFT) and manufacturing method thereof as well as display device and manufacturing method thereof

A technology of thin film transistors and manufacturing methods, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of not too high voltage, high off-current, and poor switching effect, so as to prevent the off-current from being too high , Improve the effect of stress resistance and conduction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

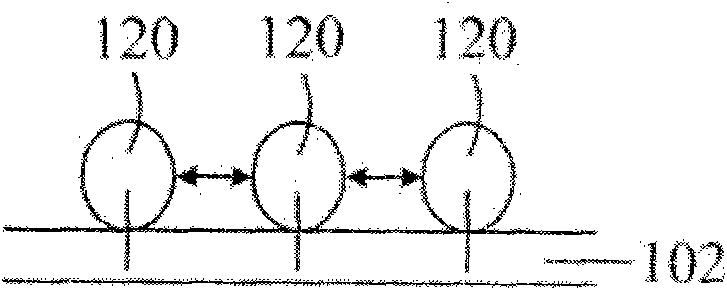

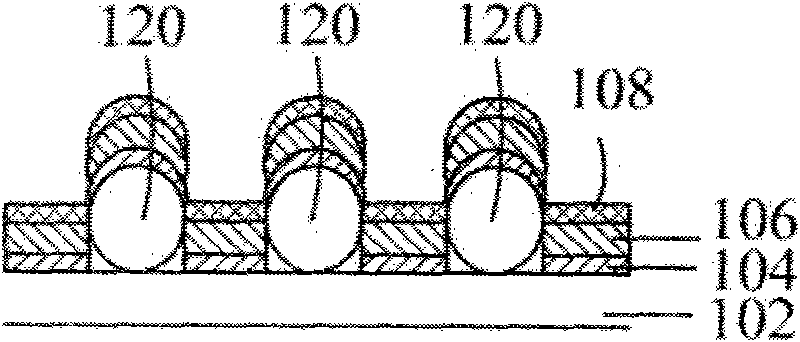

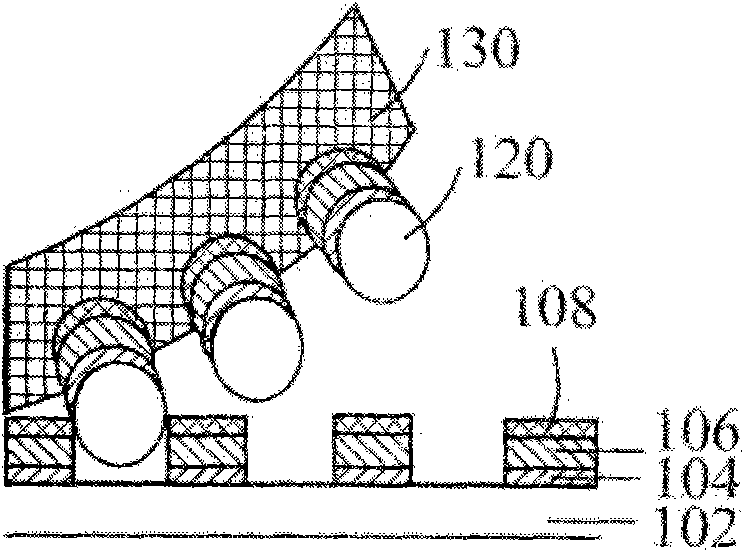

[0020] see image 3 , is a schematic structural diagram illustrating a vertical thin film transistor 300 according to an embodiment of the present invention. The upper part of the figure is a top view, and the lower part is a side view.

[0021] The vertical thin film transistor 300 is applied to a substrate 302, including a first electrode layer 304, a first insulating layer 306, a gate layer 308, a second insulating layer 314, a semiconductor layer 310, a third insulating layer 316 and a second electrode layer 312 . The feature of the present invention is that the gate layer 308 is implemented as a concentric ring structure, thereby improving the stress resistance of the vertical thin film transistor 300, protecting the semiconductor layer 310 when the substrate 302 is bent, and increasing the channel width (will be detailed later. describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com