Commutator motor

A commutator and motor technology, which is applied in the field of commutator motors, can solve the problems of brush contact area reduction, narrow space distance, spark generation, etc., and achieve the effect of improving rectification performance, improving rectification performance, and improving electrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

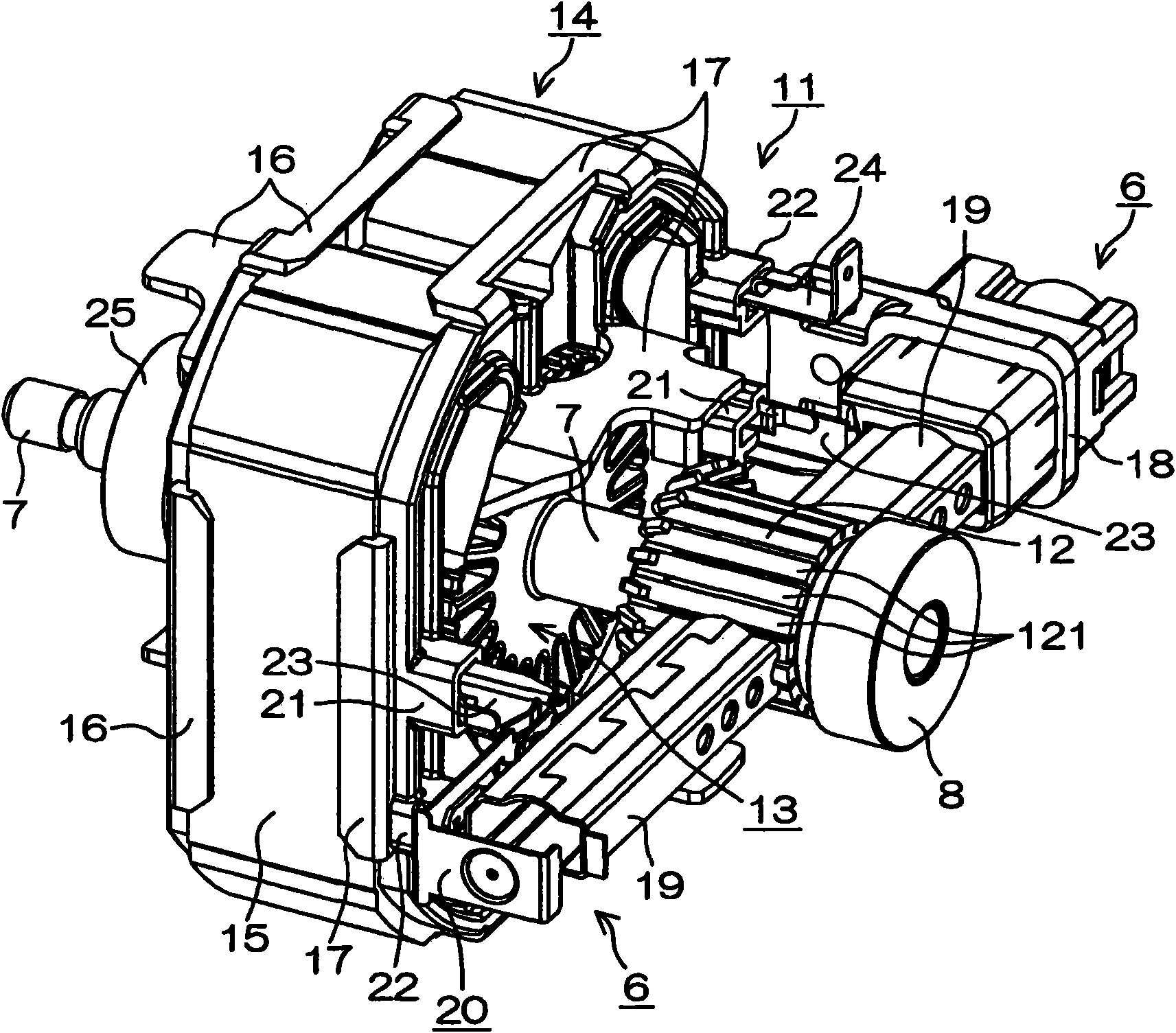

[0052] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

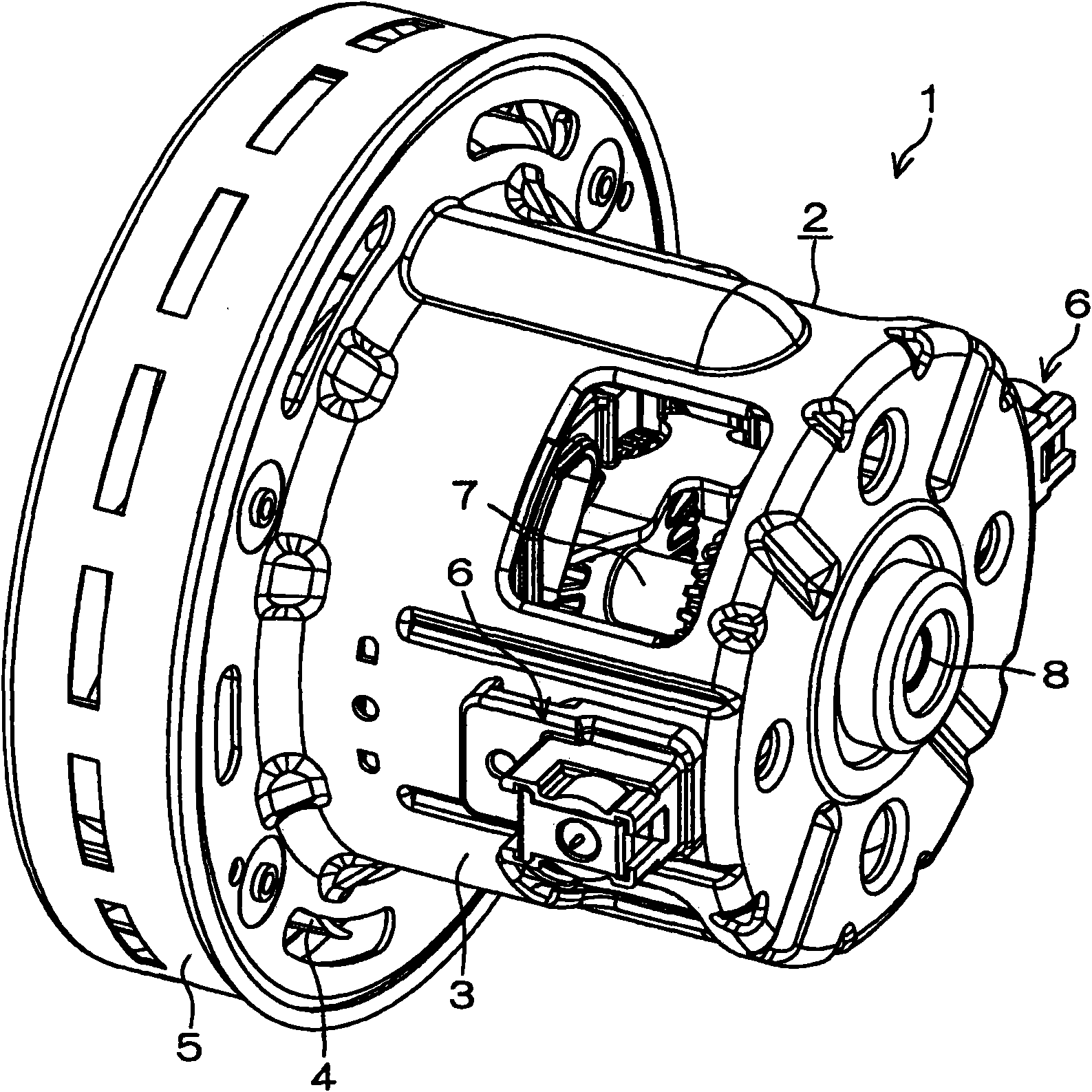

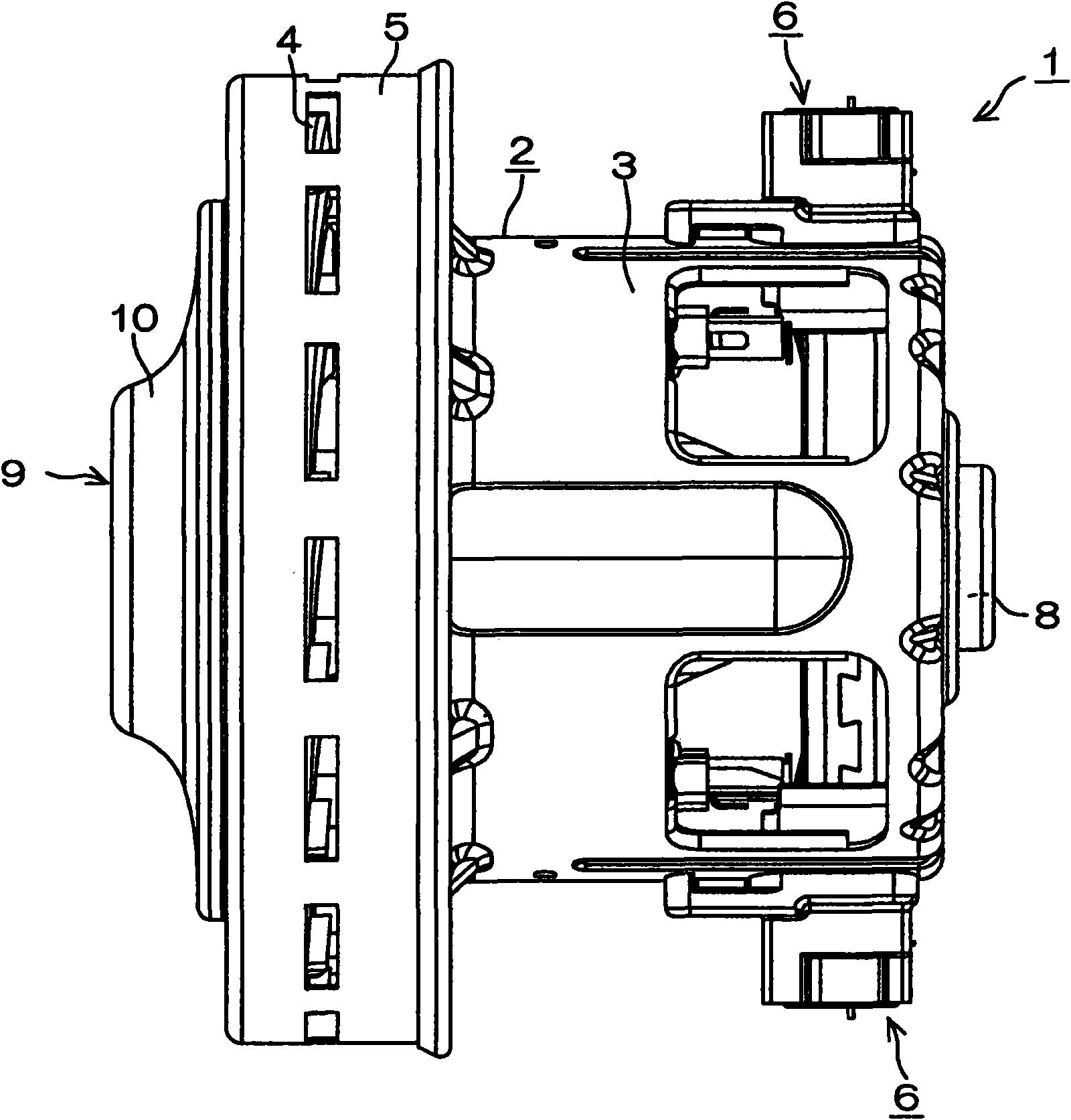

[0053] figure 1 It is a perspective view of the electric blower 1 of one embodiment seen from obliquely rearward.

[0054] A commutator motor according to one embodiment of the present invention is incorporated in the blower 1 .

[0055] exist figure 1 In the figure, 2 represents the case 2 which forms the outer shape of the electric blower 1, and this case 2 also serves as the case of the commutator motor. Case 2 includes bracket 3 covering the outside of the motor, and fan case 5 covering the outside of blower blade 4 .

[0056] A brush unit 6 is attached to the bracket 3 . Part of the brush unit 6 protrudes outward from the bracket 3 . A mounting hole for the brush unit 6 is formed in the bracket 3 , and the brush unit 6 is configured to be fitted into the mounting hole from the outside of the bracket 3 to be mounted.

[0057] In addition, in figu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap