Injection molded article and method of manufacturing the same

A technology of injection molding and manufacturing methods, applied in the direction of electrical components, magnetic field/electric field shielding, electrical equipment casing/cabinets/drawers, etc., can solve problems such as limited plastic resin, bending of injection molded products, thin product trends, etc., to ensure Stiffness, the effect of increasing the degree of freedom of choice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

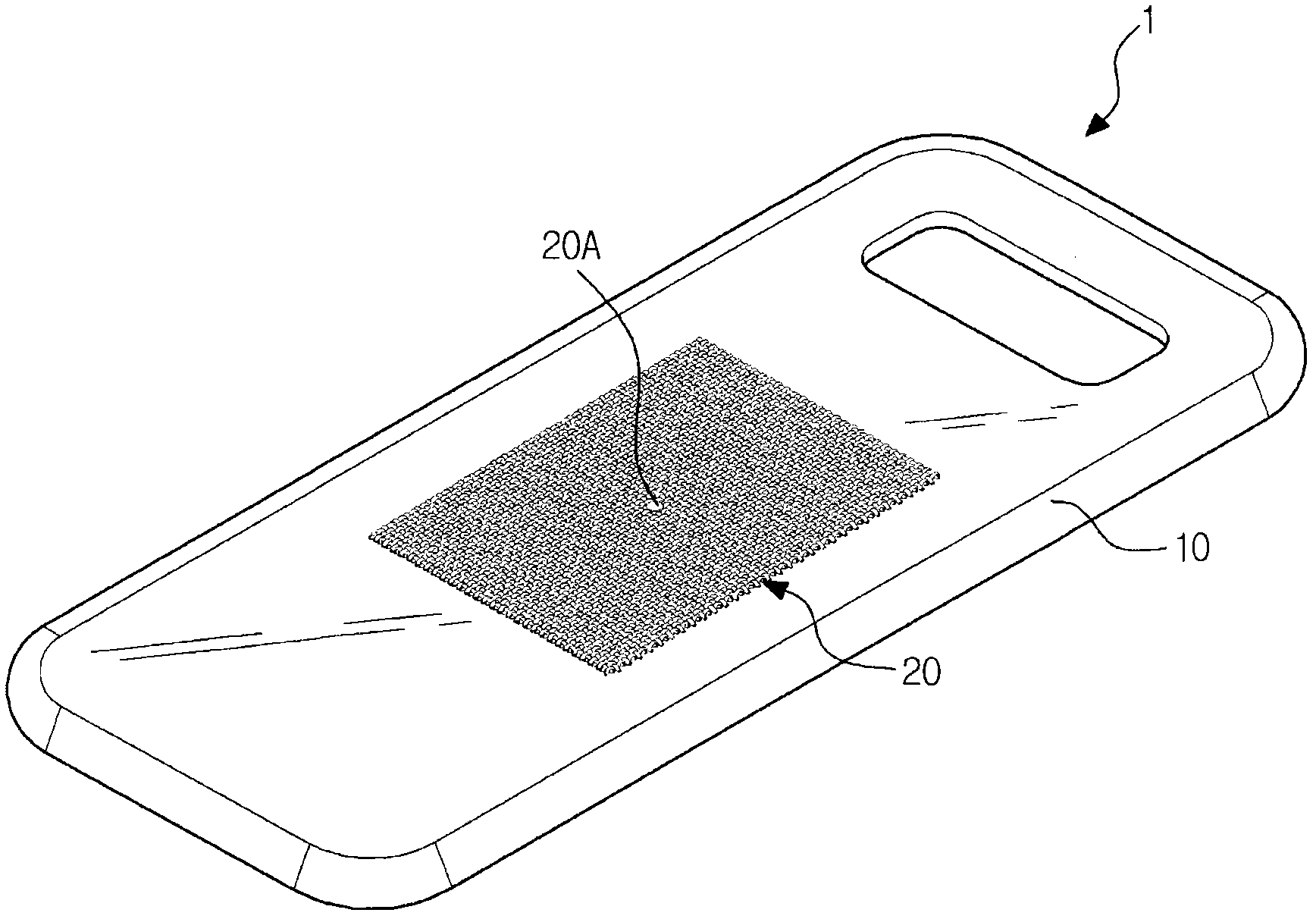

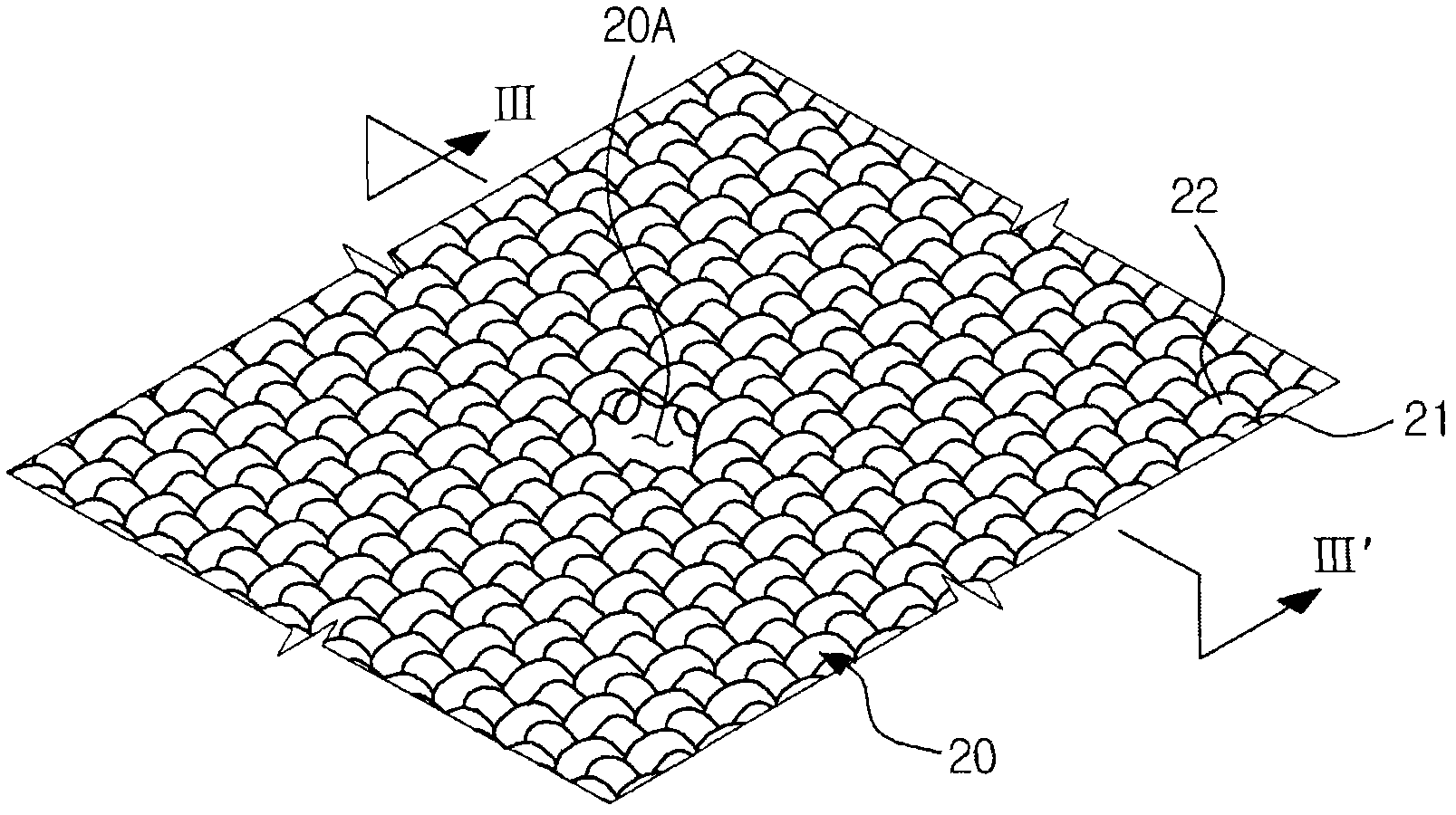

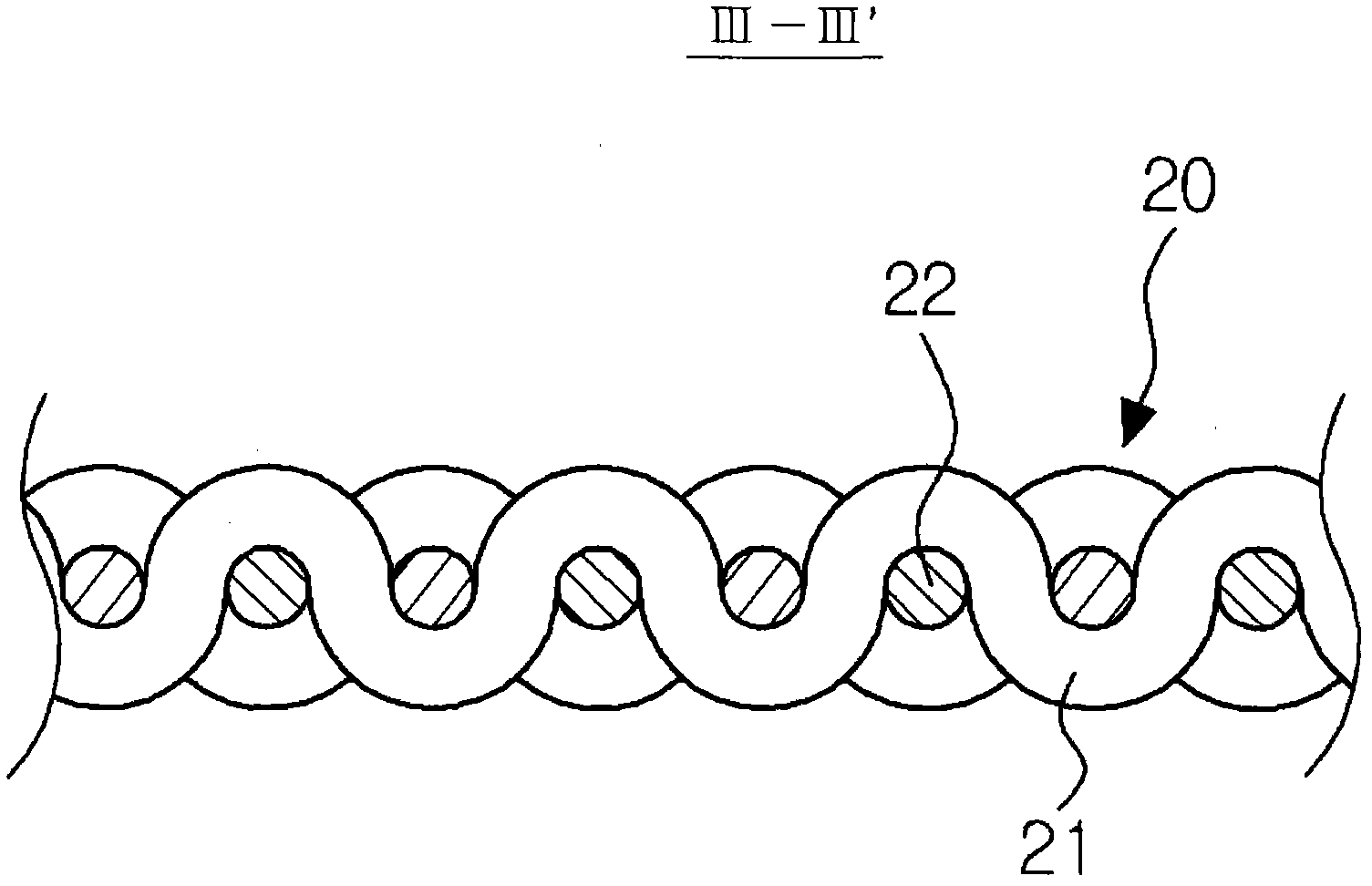

[0039] figure 1 To show a schematic diagram of a plastic injection molded product according to an embodiment of the present invention, figure 2 To enlarge the schematic diagram showing the insert molding according to the embodiment of the present invention, image 3 for along figure 2 Sectional view of line III-III'.

[0040] Such as Figure 1 to Figure 3 As shown, the injection molded article 1 according to the embodiment of the present invention includes: a substrate 10 forming the appearance of the injection molded article 1 and an insert molding 20 embedded in the substrate 10 and increasing the rigidity of the injection molded article 1 .

[0041] The base material 10 may be composed of plastic resin. Plastic resins may include transparent resins, opaque resins, and translucent resins.

[0042] The base material 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com